Surface film plasmon resonance-based metal film measuring device and method

A surface plasmon and measuring device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in precise control of air gap thickness, poor repeatability, affecting the characterization accuracy of optical constants of metal thin films, etc., and achieve precise control of the dielectric layer. The effect of thickness, small error and large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and drawings, but the protection scope of the present invention should not be limited by this.

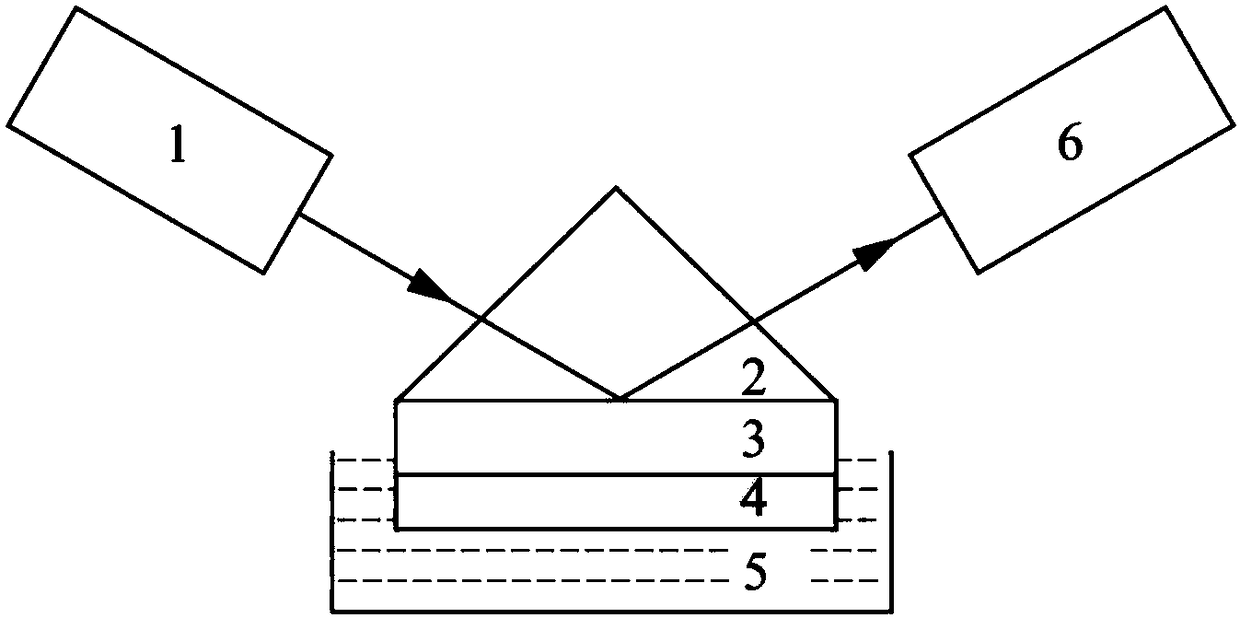

[0033] See figure 1 , figure 1 It is a schematic diagram of the structure of the metal film measuring device based on surface plasmon resonance of the present invention. It can be seen from the figure that the present invention includes an isosceles right-angle prism 2, on the bottom surface of the isosceles right-angle prism 2 is sequentially plated with a submicron thickness of the dielectric film 3 and the metal film layer 4 to be tested, and immersed in the solution 5. .

[0034] The optical path is: the light beam emitted by the ellipsometer launching arm 1 is incident on the right-angle surface of the isosceles right-angle prism 2, when the incident light is incident on the interface between the bottom surface of the isosceles right-angle prism 2 and the dielectric film 3 with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com