High-temperature high-pressure lubricant oil single-liquid-droplet evaporation and ignition device and using method thereof

A high temperature and high pressure, lubricating oil technology, applied in the direction of chemical analysis using combustion, can solve problems such as high viscosity and early volatilization of droplets, and achieve the effects of short heating time, simple steps and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

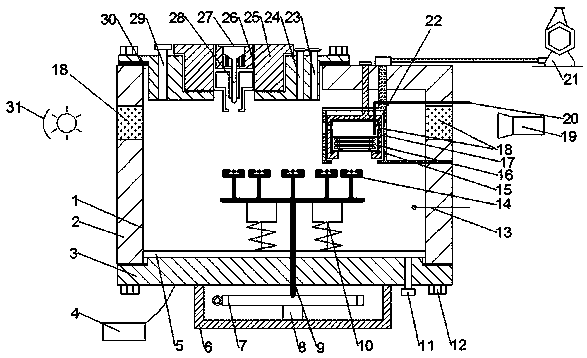

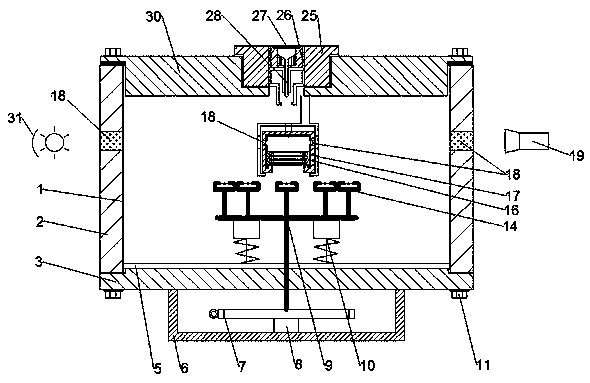

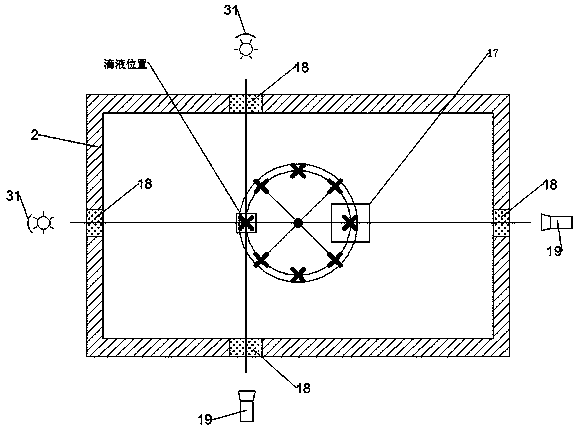

[0021] Such as figure 1 As shown, an experimental device for evaporation and spontaneous combustion of lubricating oil droplets in a high-temperature and high-pressure environment includes a closed high-pressure outer container 1 surrounded by an upper end cover 30, a lower end cover 3, and a side plate 2, and an internal high-temperature chamber inside the airtight pressure vessel 1. The heating device 16 in 17, the droplet suspension device 9, and the heat insulating material provide an adiabatic high-temperature environment and a carrier for the stable evaporation and ignition of the droplets for the experiment. The airtight high-pressure outer vessel 1 is a device that provides a high-pressure environment for the experiment. In order to facilitate installation and conduct the experiment smoothly, the shape adopts a squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com