Power module HTRB (high temperature reverse bias) reliability test system

A test system and power module technology, which is applied in the field of power module HTRB reliability test system, can solve the problems of failure to keep up with the development and progress of devices, operability, stability, and efficiency that are not suitable for actual production applications, and test systems that cannot be used. Electrical reliability test and other issues, to achieve the effect of high temperature setting accuracy, flexible and convenient testing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below. Examples of the embodiments are shown in the accompanying drawings, in which the same reference numerals in each figure represent the same parts. The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and are not understood as limitations to the present invention.

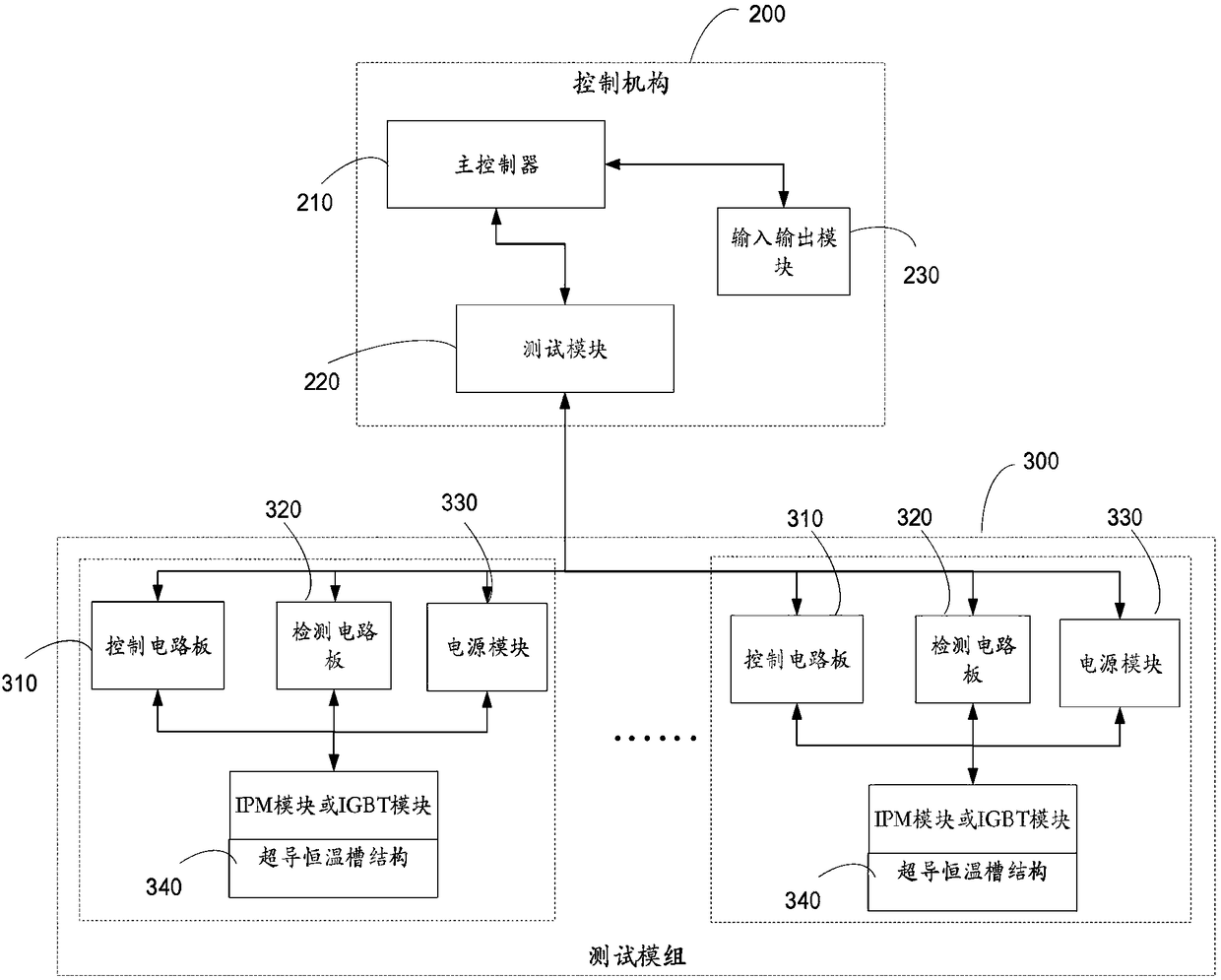

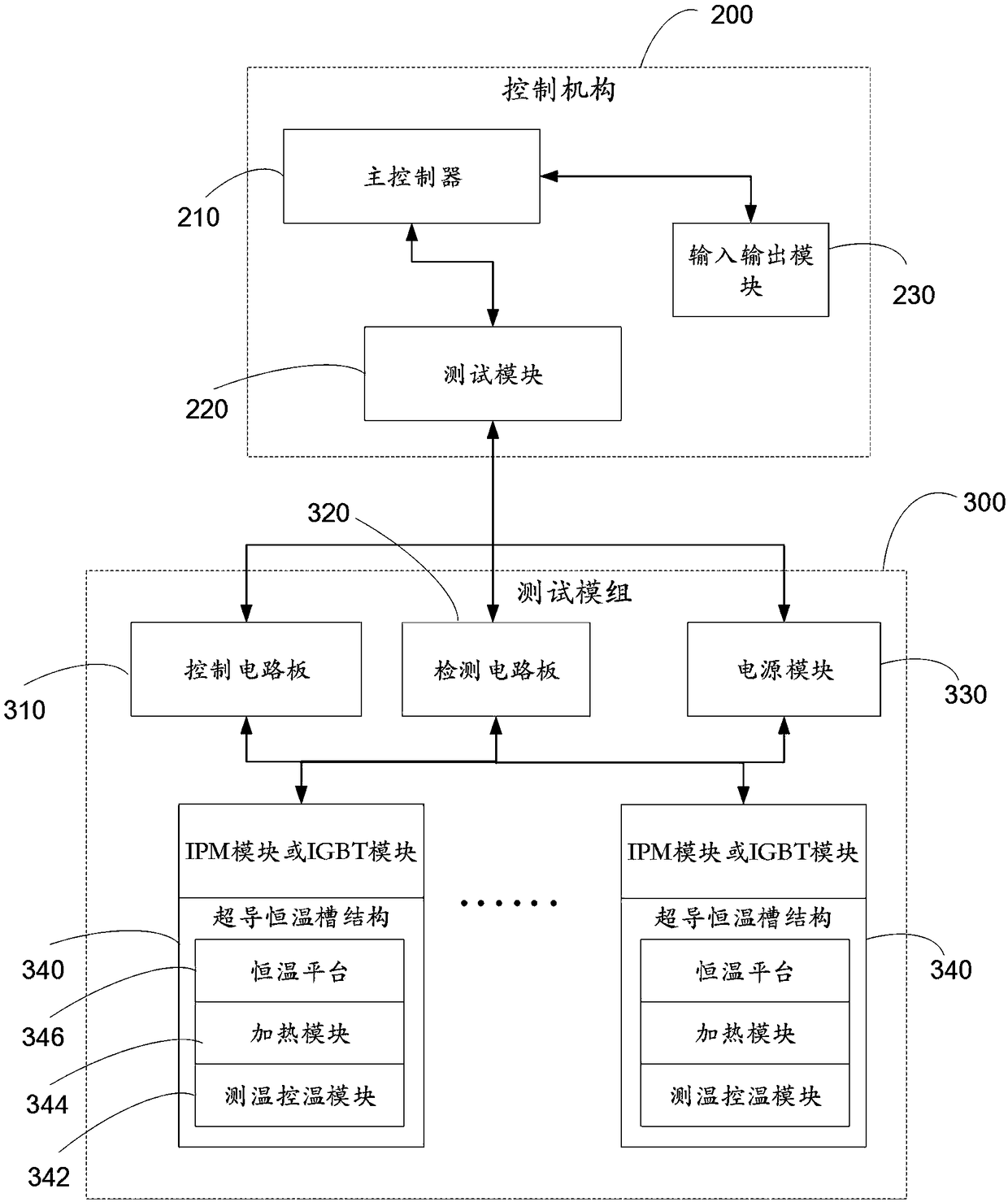

[0032] Such as Figure 1 to Figure 3 As shown, the present invention proposes a power module HTRB reliability test system, which includes a chassis 100, a communication connection control mechanism 200 and a test module 300 provided on the chassis 100. The IPM module or IGBT module is tested by the test module 300, and the control mechanism 200 controls the test process. The IPM module or IGBT module to be tested is placed in the test module 300 with a certain ambient temperature (the ambient temperature is set according to the specifications of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com