Automatic pin device

A pin insertion device and automatic technology, applied in the field of automatic pin insertion devices, can solve the problems of low pin insertion efficiency and uncontrollable pin quality, and achieve the effects of improving pin insertion accuracy and improving pin insertion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

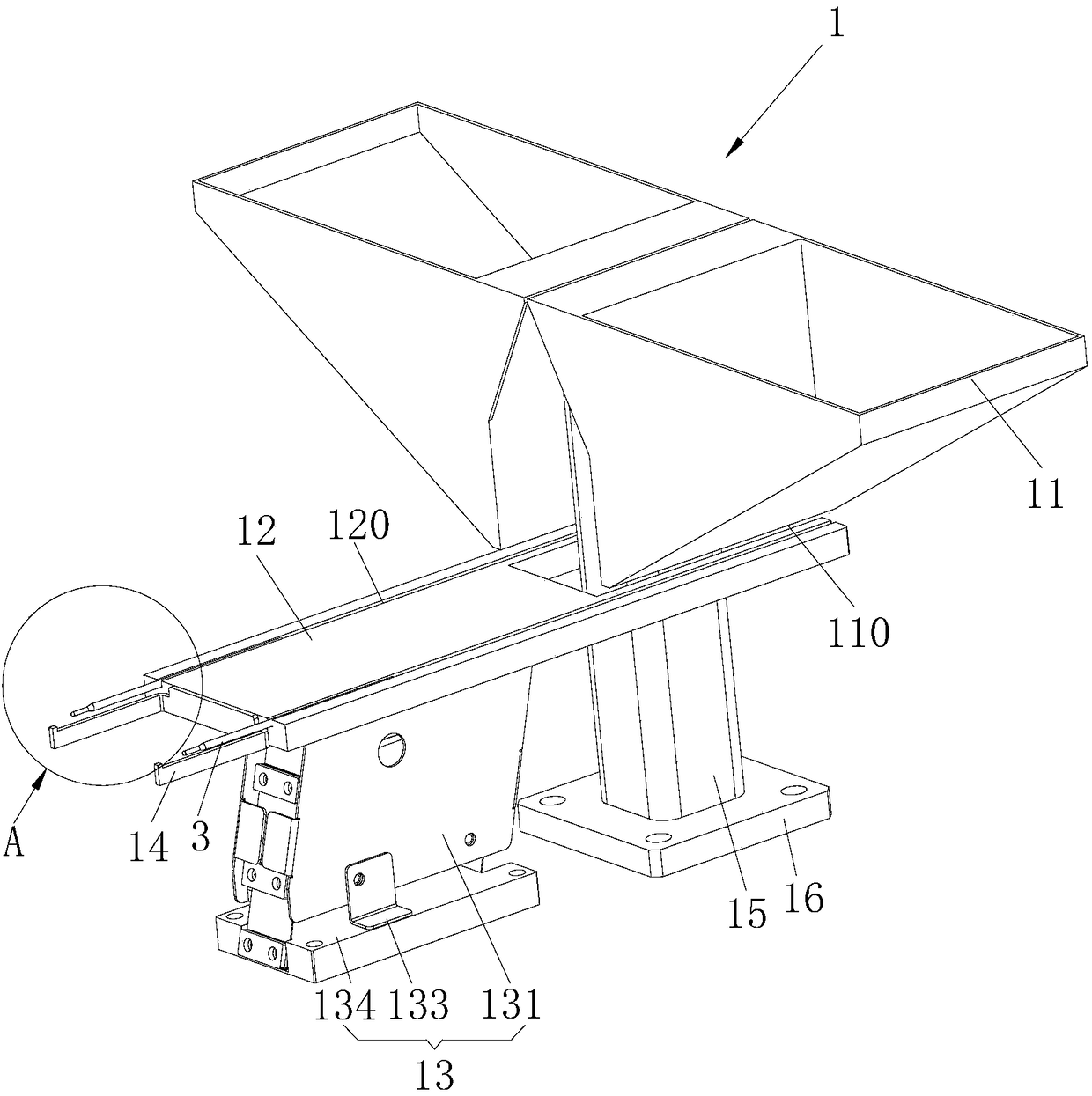

[0044] Further, see image 3 and Figure 5 , as a specific embodiment of the automatic pin insertion device provided by the present invention, the direct vibration assembly 13 includes a vibration housing 131 and a vibration motor 132, the vibration motor 132 is fixed on the inner wall of the vibration housing 131, and the vibration housing 131 and The material guide plate 12 abuts against each other. When the vibration motor 132 works, the vibration housing 131 is vibrated, thereby driving the material guide plate 12 to vibrate, and realizing the movement of the welding needle 3 in the material guide groove 120. The cost of the vibration motor 132 is low, and the vibration of the material guide plate 12 is driven by the vibration motor 132, which can reduce the production cost.

[0045] Further, see image 3 , as a specific embodiment of the automatic pin insertion device provided by the present invention, the direct vibration assembly 13 further includes a first fixing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com