Hybrid acoustic wave resonator of bulk acoustic wave resonator and surface acoustic wave resonator

A technology of bulk acoustic wave resonators and acoustic wave resonators, which is applied in the field of hybrid acoustic wave resonators, can solve problems such as cracking and warping, achieve the effect of reducing the process flow and avoiding piezoelectric substrate cracking or serious warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

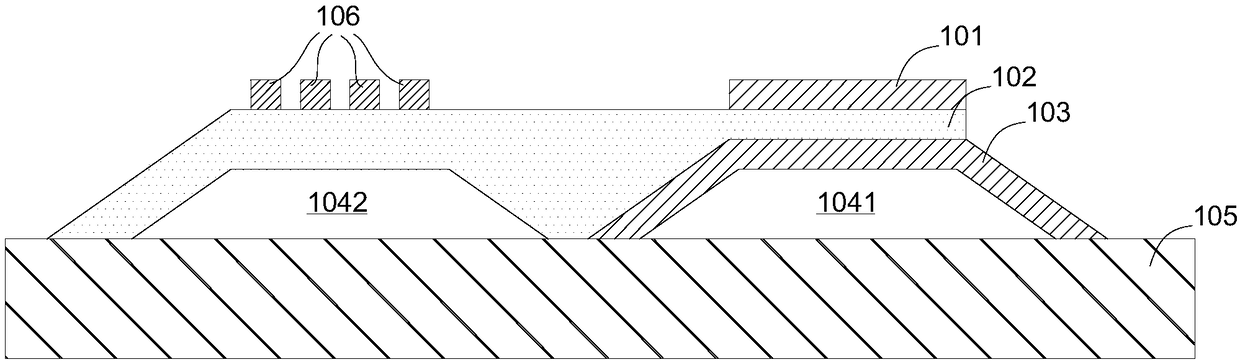

[0018] This embodiment provides a hybrid acoustic wave resonator of a bulk acoustic wave resonator and a surface acoustic wave resonator, such as figure 1 As shown, it includes: a substrate 105, a bottom electrode 103, a piezoelectric layer 102, and a top electrode 101 arranged in sequence from bottom to top, and a first air cavity 1041 is formed between the substrate 105 and the bottom electrode 103, thereby forming a bulk acoustic wave resonator ; An interdigital electrode 106 is formed on the same piezoelectric layer 102, and a second air cavity 1042 is formed between the substrate 105 and the piezoelectric layer 102, thereby forming a surface acoustic wave resonator. The interdigital electrode 106 is a finger-like or comb-like electrode with a periodic pattern in its plane.

[0019] Both the first air cavity 1041 and the second air cavity 1042 are raised air cavities, and may also be a combination of different reflective surfaces.

[0020] Preferably, in the surface acous...

Embodiment 2

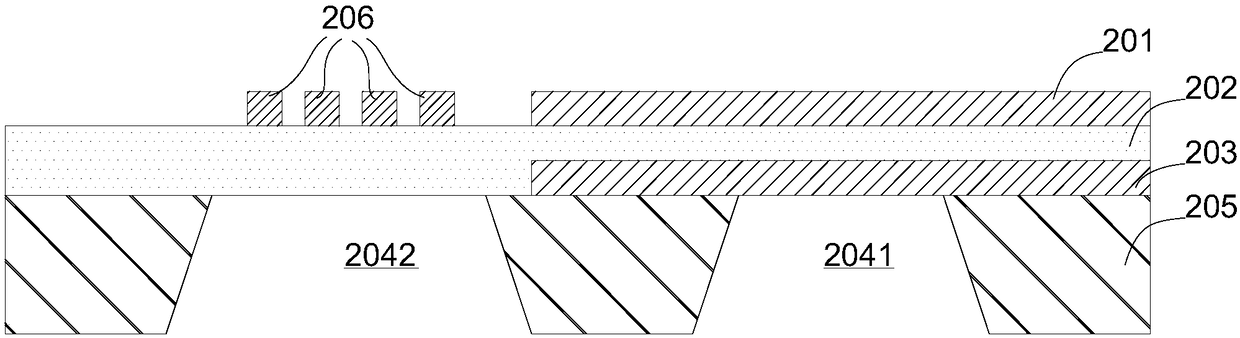

[0023] This embodiment provides a hybrid acoustic wave resonator of a bulk acoustic wave resonator and a surface acoustic wave resonator, such as figure 2 As shown, it includes: a substrate 205, a bottom electrode 203, a piezoelectric layer 202, and a top electrode 201 arranged in sequence from bottom to top, and a first air cavity 2041 is formed between the substrate 205 and the bottom electrode 203, thereby forming a bulk acoustic wave resonator ; Interdigital electrodes 206 are formed on the same piezoelectric layer 202, and a second air cavity 2042 is formed between the substrate 205 and the piezoelectric layer 202, thereby forming a surface acoustic wave resonator. The interdigital electrode 206 is a finger-like or comb-shaped electrode with a periodic pattern in its plane.

[0024] Both the first air cavity 2041 and the second air cavity 2042 are air cavities formed by etching holes on the substrate, and may also be a combination of different reflective interfaces.

[...

Embodiment 3

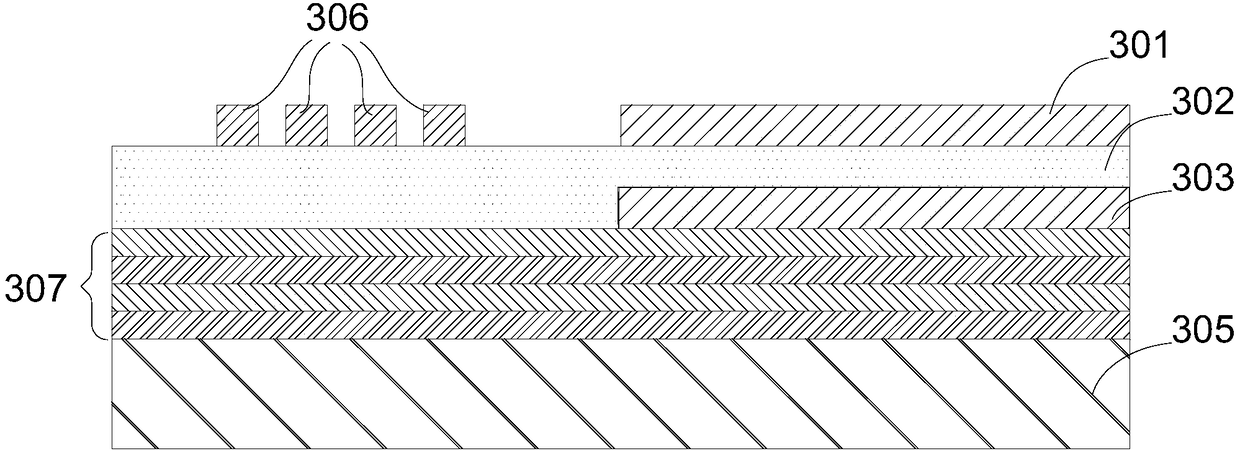

[0028] This embodiment provides a hybrid acoustic wave resonator of a bulk acoustic wave resonator and a surface acoustic wave resonator, such as image 3 As shown, it includes: a substrate 305, a bottom electrode 303, a piezoelectric layer 302, and a top electrode 301 arranged in sequence from bottom to top, and the substrate 305 and the bottom electrode 303 are formed by overlapping materials with high acoustic resistance and low acoustic resistance. The Bragg reflector 307 is formed to form a bulk acoustic wave resonator; the interdigitated electrodes 306 are formed on the same piezoelectric layer 302 to form a surface acoustic wave resonator. The interdigital electrode 306 is a finger-like or comb-like electrode with a periodic pattern in its plane.

[0029] In this embodiment, the first reflective layer and the second reflective layer can be integrated, that is, only one Bragg reflector 307 formed by overlapping materials with high acoustic resistance and low acoustic res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com