Magnet filter for heating system

A heating system, using magnet technology, applied in the direction of fixed filter element filter, filtration separation, filtration treatment, etc., can solve the problems of incomplete filtration and inability to magnetize water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

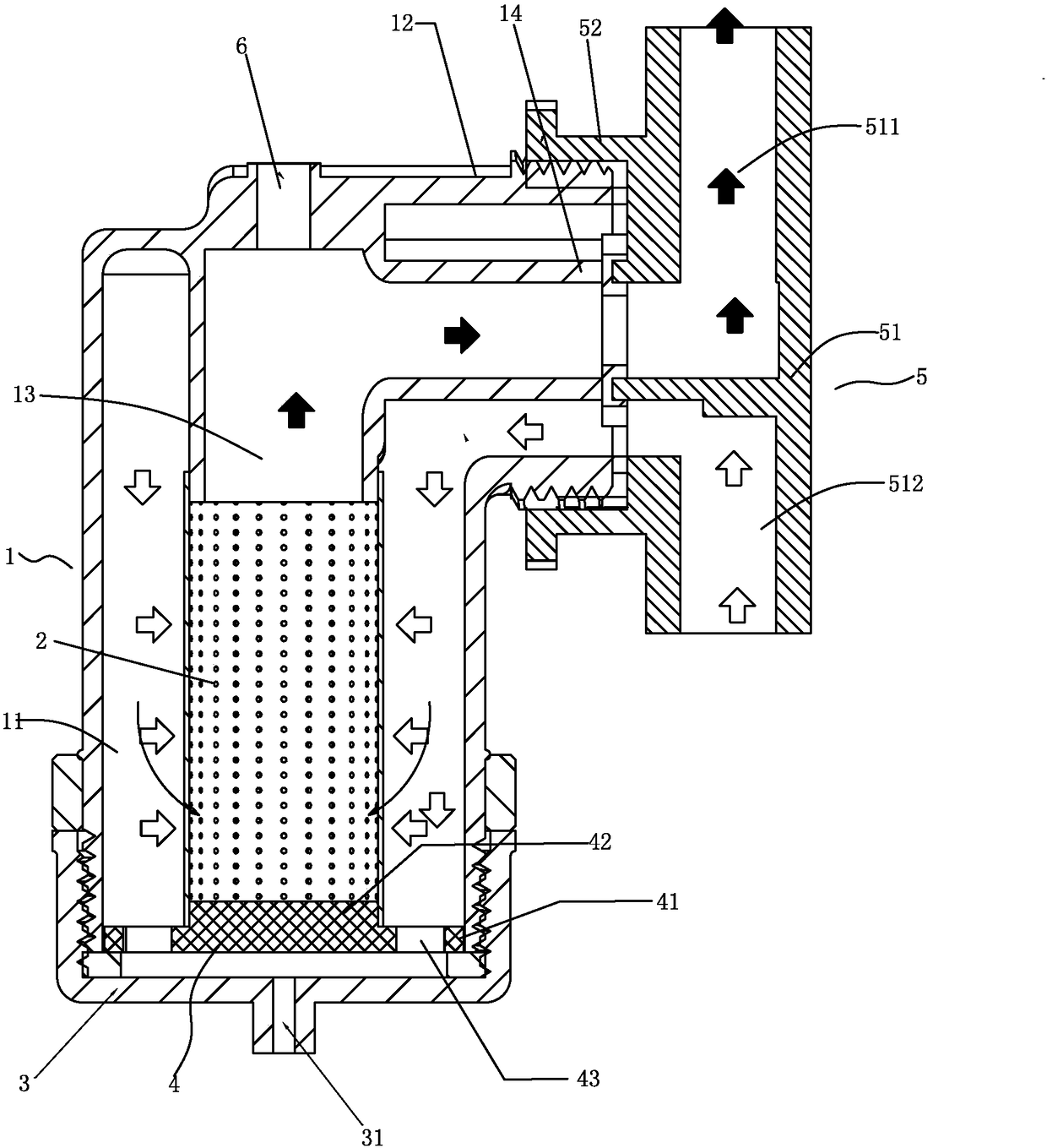

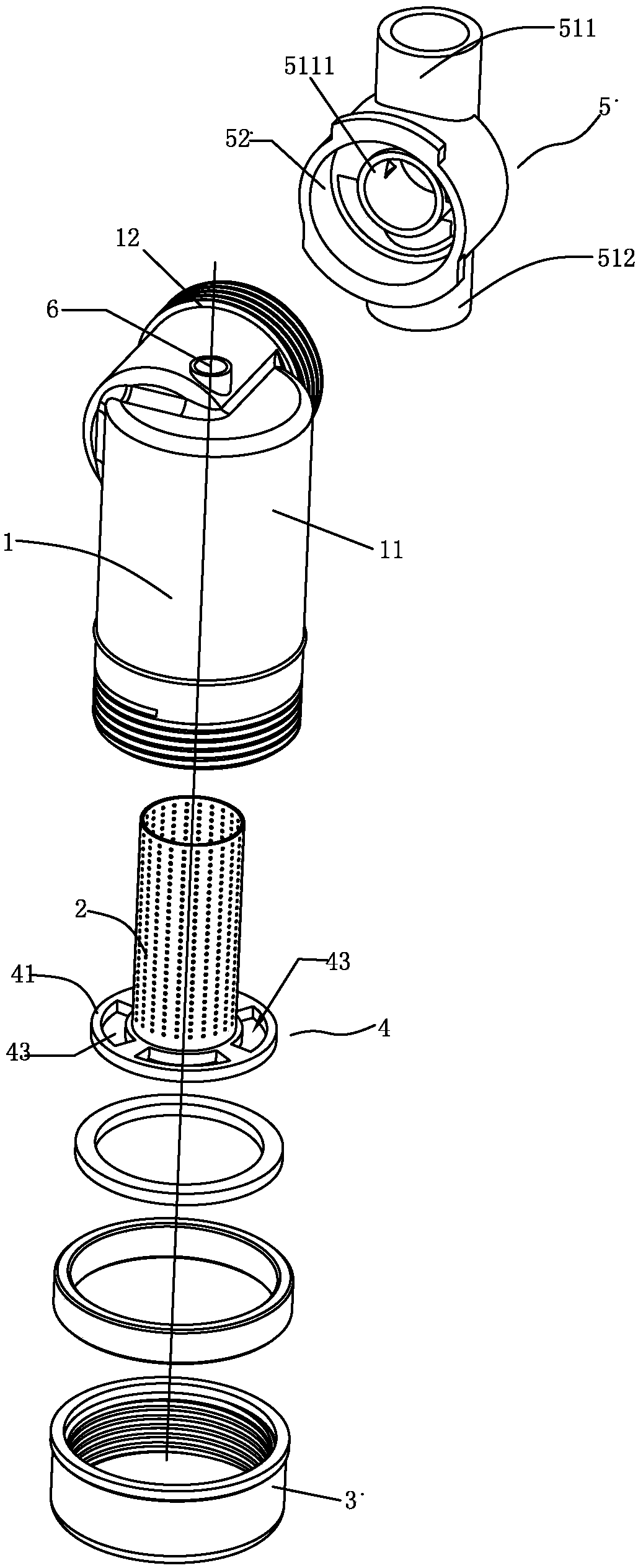

[0025] Such as figure 1 As shown, a magnet filter for a heating system includes a housing 1 and a filter core 2 .

[0026] The housing 1 includes a body 11 with a lower opening, a water inlet 12 arranged on the upper part of the body, a water guide 13 arranged in the body, and a water outlet 14 arranged in the water inlet 12. The water guide 13 is connected to the body. There is a gap between the parts 11, and there is a gap between the water outlet interface 14 and the water inlet interface 12; the top of the water guide pipe 13 is fixedly connected to the top plate of the body part 11; the water outlet interface 14 is connected to the water guide pipe 13;

[0027] The filter core 2 has upper and lower openings, and the filter core 2 is made of stainless steel;

[0028] It also includes a bottom cover 3, a magnet 4 and a water inlet and outlet part 5,

[0029] The water inlet and outlet part 5 includes an inlet and outlet water body part 51 and an external interface 52. The...

Embodiment 2

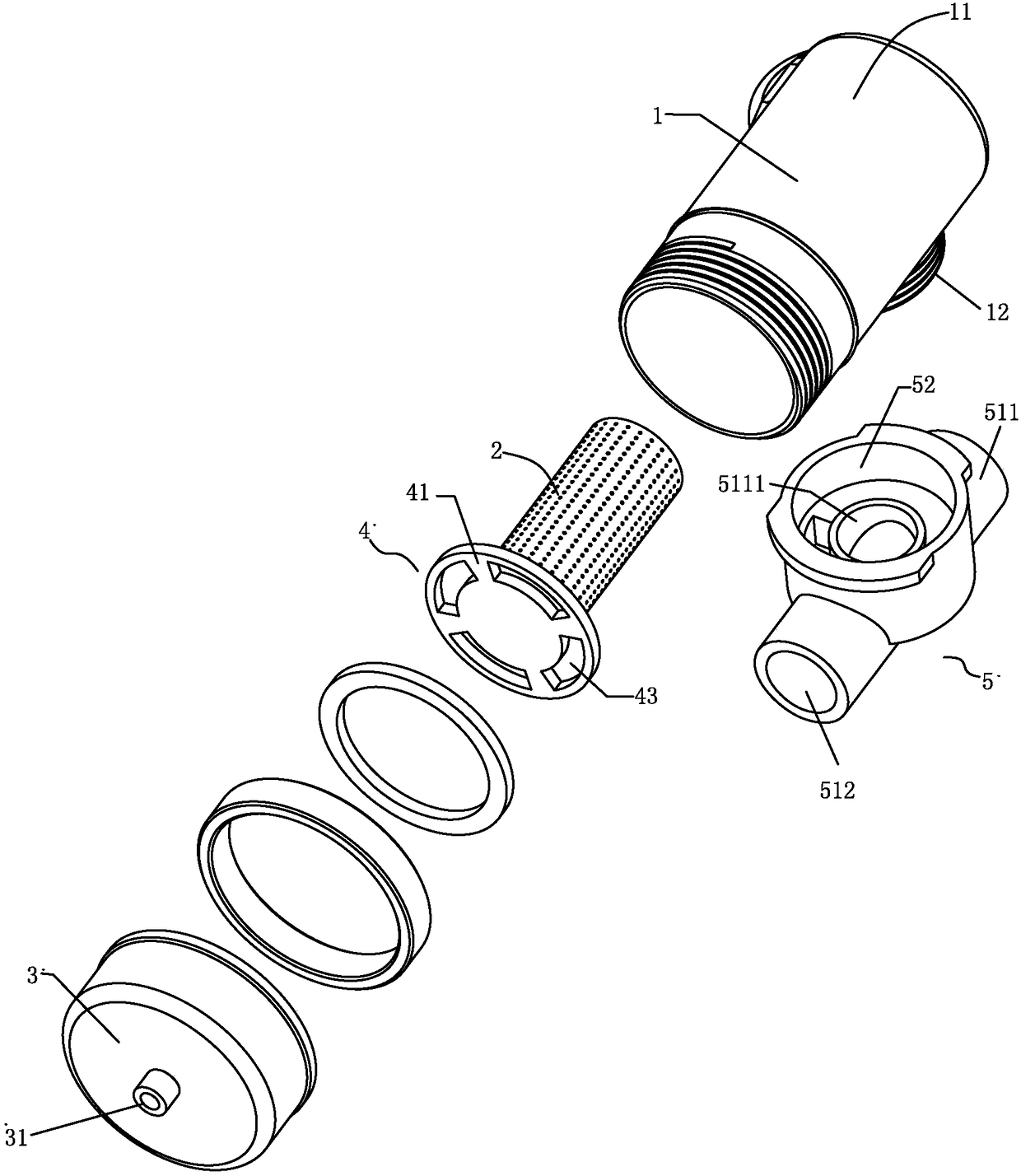

[0038] Such as Figure 4 As shown, the water outlet at the lower part of the water outlet pipe part 511 is provided with a circular interface 5111; the outer interface 52 of the water inlet and outlet part 5 is provided with a retaining ring 521;

[0039] It also includes a fastening screw sleeve 7; one end of the fastening screw sleeve 7 is provided with a circular end plate;

[0040] The ring end plate cooperates with the retaining ring 521, and the fastening screw sleeve 7 is screwed with the water inlet port 12 of the housing 1; the circular port 5111 is docked with the water outlet port 14 of the housing and is liquid-tight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com