All composite wingtip winglet for high-aspect-ratio wing

A composite material, high aspect ratio technology, applied in aircraft parts, aircraft control, aircraft stability and other directions, can solve the problems of difficult UAV design, small internal space of winglets, etc., to achieve the integrated design of structure and function , Reduce the manufacturing cost, the effect of small shape influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

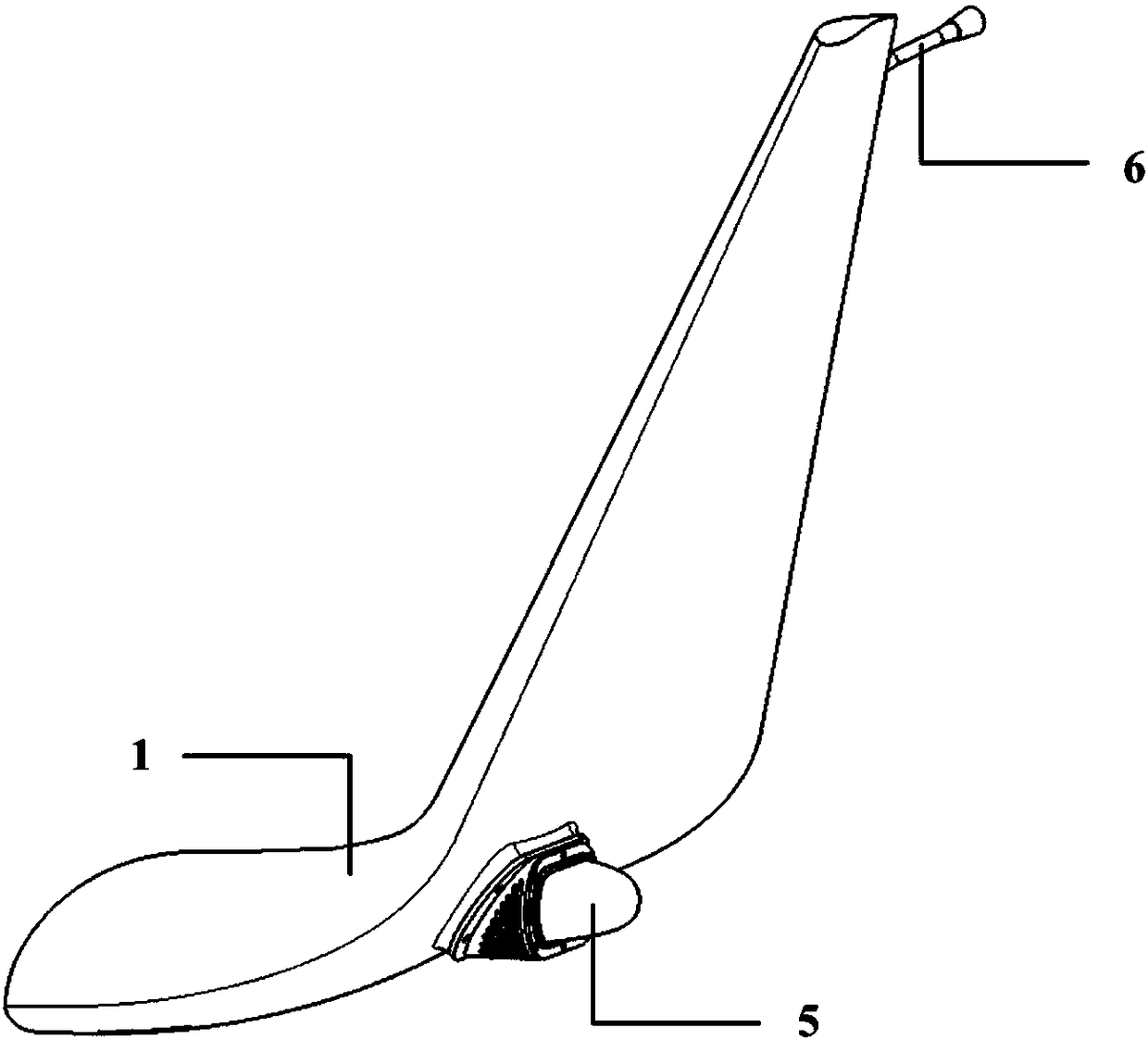

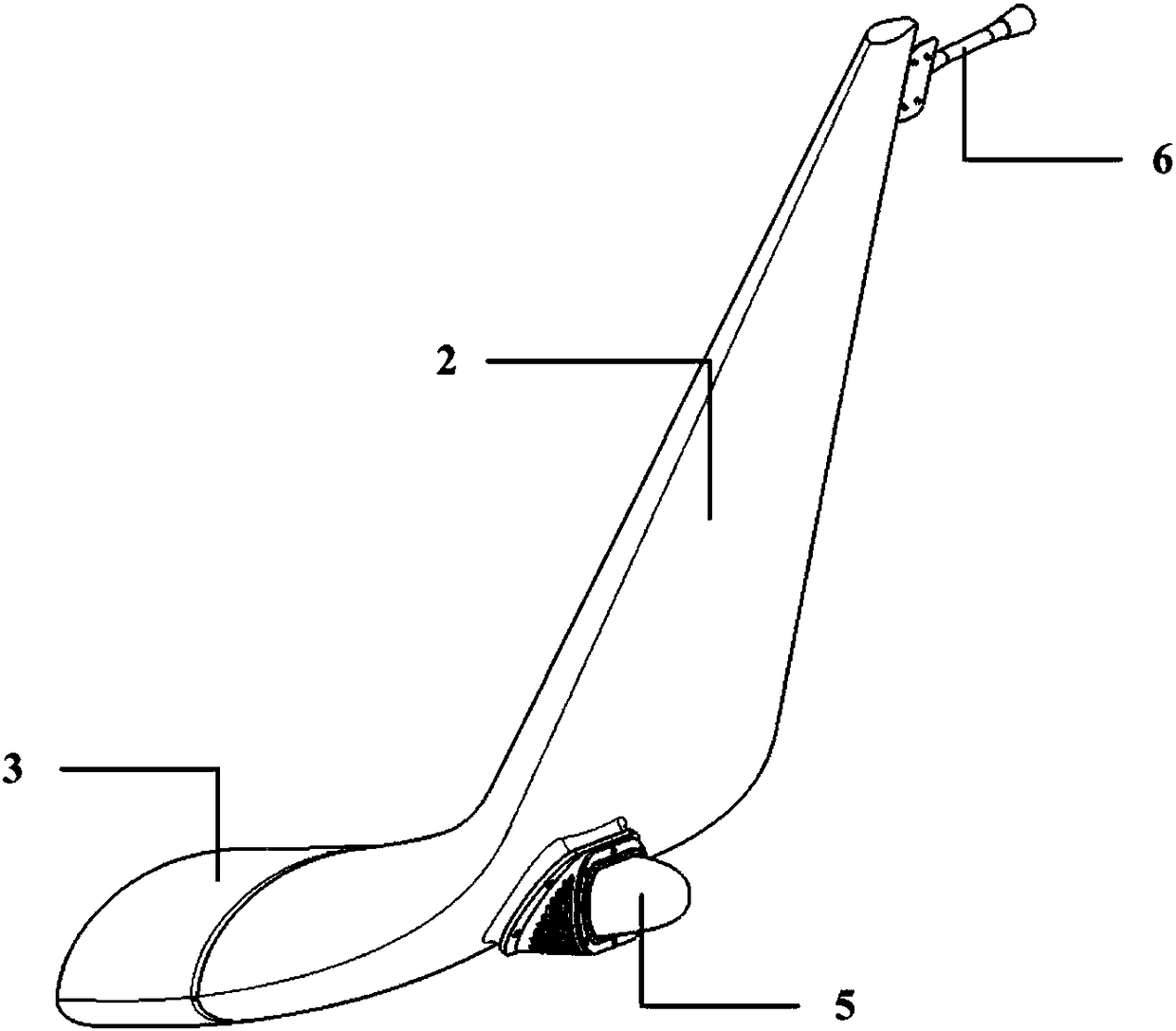

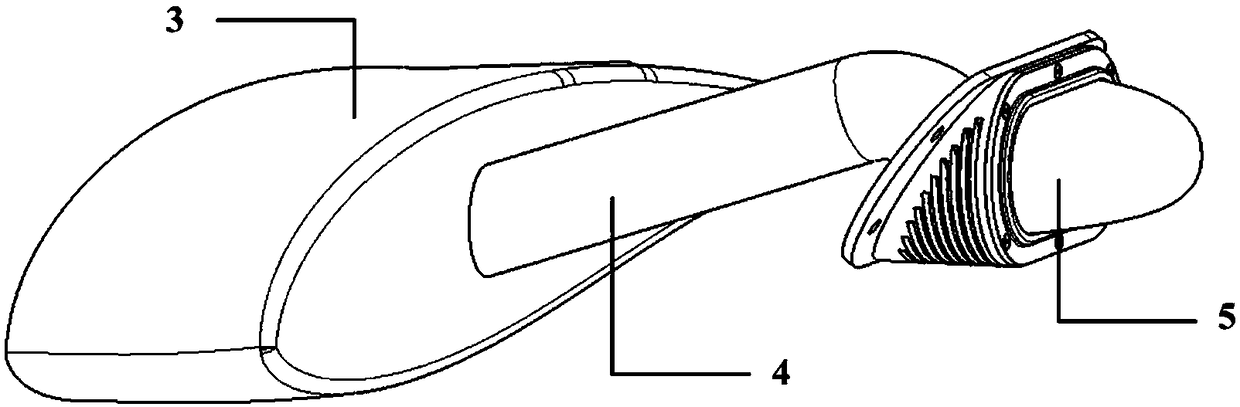

[0024] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 3 .

[0025] Such as Figure 1-3 As shown, an all-composite winglet suitable for a wing with a large aspect ratio, the winglet includes a skin 1, a foam core 2, an edge banding rib 3, and a round tube 4, and the skin 1 is cylindrical Cavity structure, the foam core 2 is placed in the cavity of the skin 1, and the edge sealing rib 3 is placed on the edge of the cavity of the skin 1; it is characterized in that the round tube 4 is placed in the foam core 2, and the skin 1 and the The edge sealing rib 3 communicates, the navigation light 5 is installed on the outer surface of the skin 1, and communicates with the circular tube 4, and the circuit of the navigation light 5 leads to the main airfoil of the wing through the circular tube 4.

[0026] The skin 1, the edge rib 3 and the round pipe 4 are made of the same glass fiber composite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com