Quick treatment method for pipe blocking of cast-in-place pile

A processing method and cast-in-place pile technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of design scheme delays, pile breakage, etc., and achieve the effect of easy technology and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

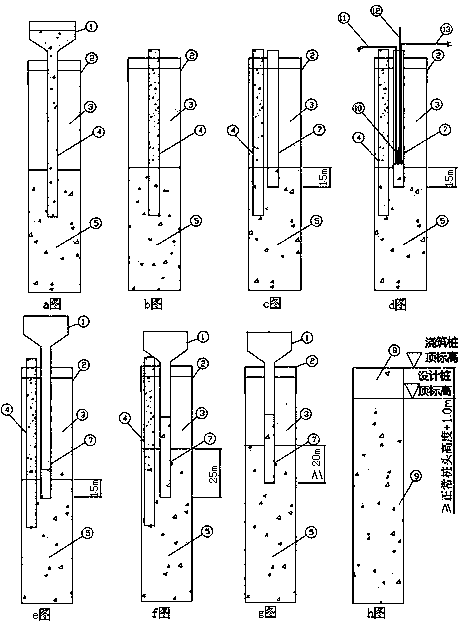

[0028] Such as figure 1 As shown, when the present invention is suitable for pouring cast-in-situ pile concrete using the conduit method, the concrete 5 is stuck, and the concrete 5 cannot be poured further, and the concrete outside the stuck conduit 4 still has certain fluidity and continuous pouring. Sustainability here means that the installation of the standby conduit 7 is completed and the pouring of concrete is started, and this period of time must be sufficient or sufficient. Only when the above-mentioned conditions are met can the method of the present invention be started.

[0029] Using the technical method of this invention, it is also required that the construction site be equipped with lifting equipment with the ability to lift the stuck conduit 4 out of the pile hole (generally, one crane with a lifting capacity of more than 25 tons); a set of spare conduits 7, and the inner diameter of the standby conduits can be 35 ~40cm, the calculation method of its wall thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com