Composite anticorrosion coating process based on stainless steel material

A technology of anti-corrosion coating and stainless steel, which is applied in coatings, devices for coating liquid on the surface, and pretreatment of surfaces, etc. It can solve problems such as harsh environmental conditions, unfavorable energy-saving rings, and poor coating effects, so as to reduce operating costs , save resources and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

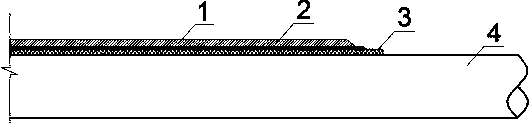

Image

Examples

Embodiment 1

[0023] Composite anti-corrosion coating process based on stainless steel It includes the following steps:

[0024] (1) The steel pipe after the surface purification treatment is transported from the pipe inlet platform to the derusting machine for fully enclosed surface sandblasting and derusting. The double shot blasting process is adopted. The abrasive material of the first sandblasting machine is stainless steel shot and The weight ratio of stainless steel grit is 1:2 as the shot blasting material. The second sandblasting machine abrasive chooses stainless steel grit as the shot blasting material. Turn on the shot blasting equipment and air compressor. The surface of the pipe body, so that the surface of the pipe body reaches a certain roughness, and the shot blasting process is completed; after the shot blasting, the quality inspection is carried out to make the final sandblasting rust removal standard reach Sa3 level, and the depth of the anchor pattern is 60-100μm, the pe...

Embodiment 2

[0029] Composite anti-corrosion coating process based on stainless steel It includes the following steps:

[0030] (1) The steel pipe after the surface purification treatment is transported from the pipe inlet platform to the derusting machine for fully enclosed surface sandblasting and derusting. The double shot blasting process is adopted. The abrasive material of the first sandblasting machine is stainless steel shot and The weight ratio of stainless steel grit is 1:1 as the shot blasting material. The second sandblasting machine abrasive chooses stainless steel grit as the shot blasting material. Turn on the shot blasting equipment and air compressor. The surface of the pipe body, so that the surface of the pipe body reaches a certain roughness, and the shot blasting derusting process is completed; after the shot blasting, the quality inspection is carried out to make the final sandblasting derusting standard reach Sa3 level, the depth of the anchor pattern is 60 µm, and th...

Embodiment 3

[0035] Composite anti-corrosion coating process based on stainless steel It includes the following steps:

[0036] (1) The steel pipe after the surface purification treatment is transported from the pipe inlet platform to the derusting machine for fully enclosed surface sandblasting and derusting. The double shot blasting process is adopted. The abrasive material of the first sandblasting machine is stainless steel shot and The weight ratio of stainless steel grit is 1:3 as the shot blasting material. The second sandblasting machine abrasive chooses stainless steel grit as the shot blasting material. Turn on the shot blasting equipment and air compressor, and the shot blasting material is thrown to the tube by centrifugal force. The surface of the pipe body, so that the surface of the pipe body reaches a certain roughness, and the shot blasting derusting process is completed; after the shot blasting, the quality inspection is carried out to make the final sandblasting derusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com