Precision casting slurry wetting and shell manufacturing center

A technology of precision casting and slurry dipping, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of being unsuitable for multi-variety and small batch production, unsuitable for automatic production lines, and affecting the promotion and use of equipment, etc., to achieve a solid structure Durable, Inexpensive, Well-Designed Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

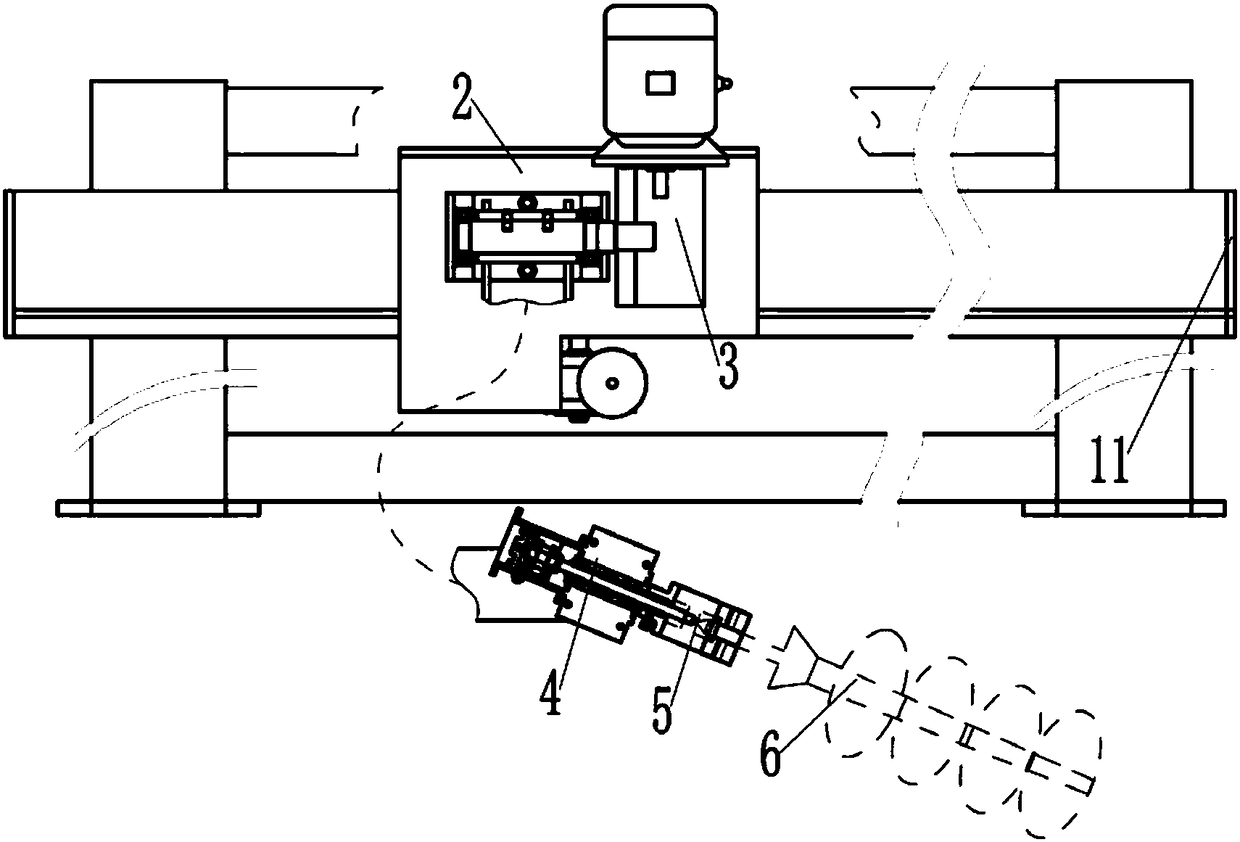

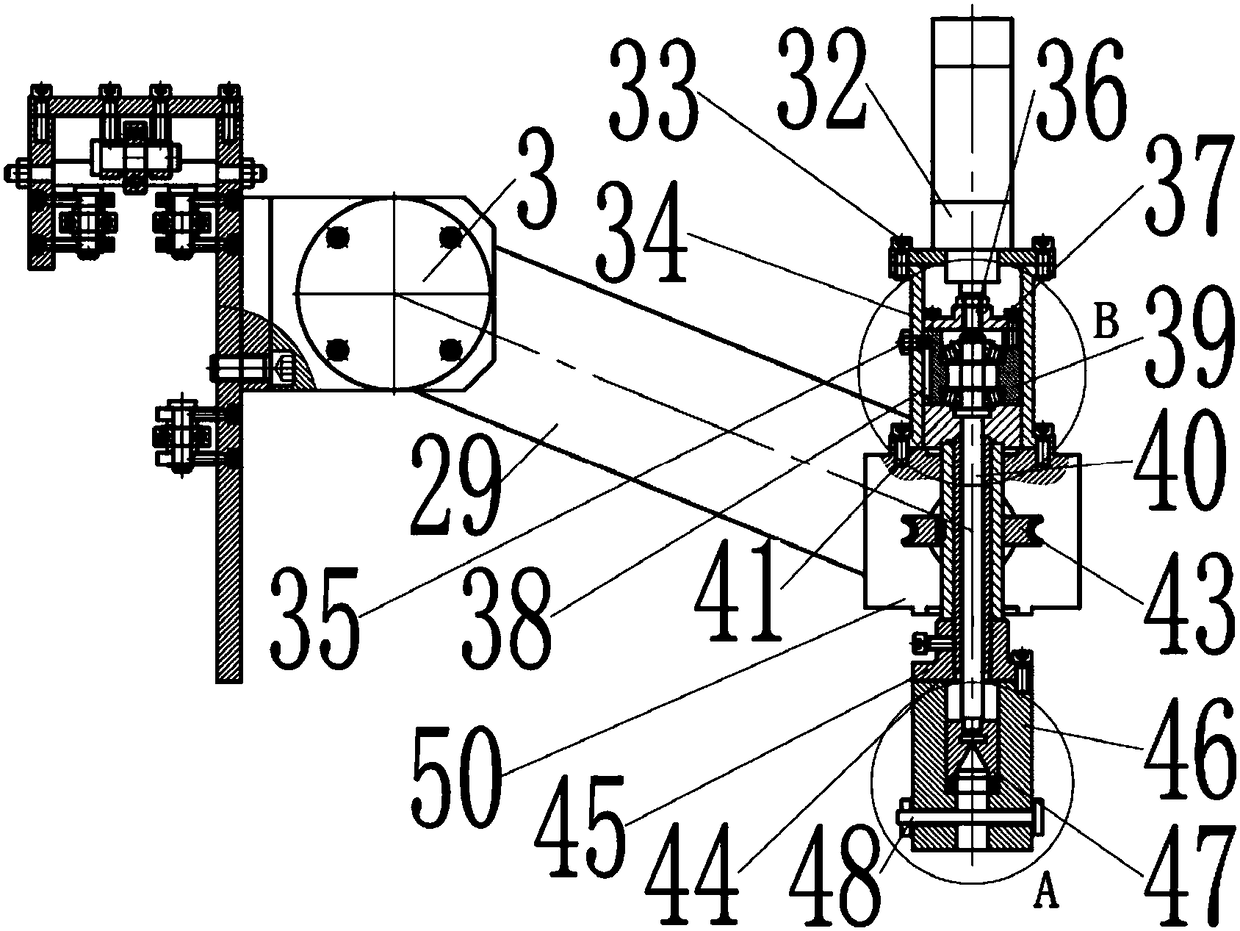

[0035] Such as Figure 1-6 Shown: the present invention comprises frame, the guide rail support device 2 that is installed on the frame, the swing arm device 3 that is installed on the guide rail support device 2, the overturn device 4 that is installed on the swing arm device 3 and is installed on the overturn device 4 and a grabbing device 5 for grabbing a wax pattern 6.

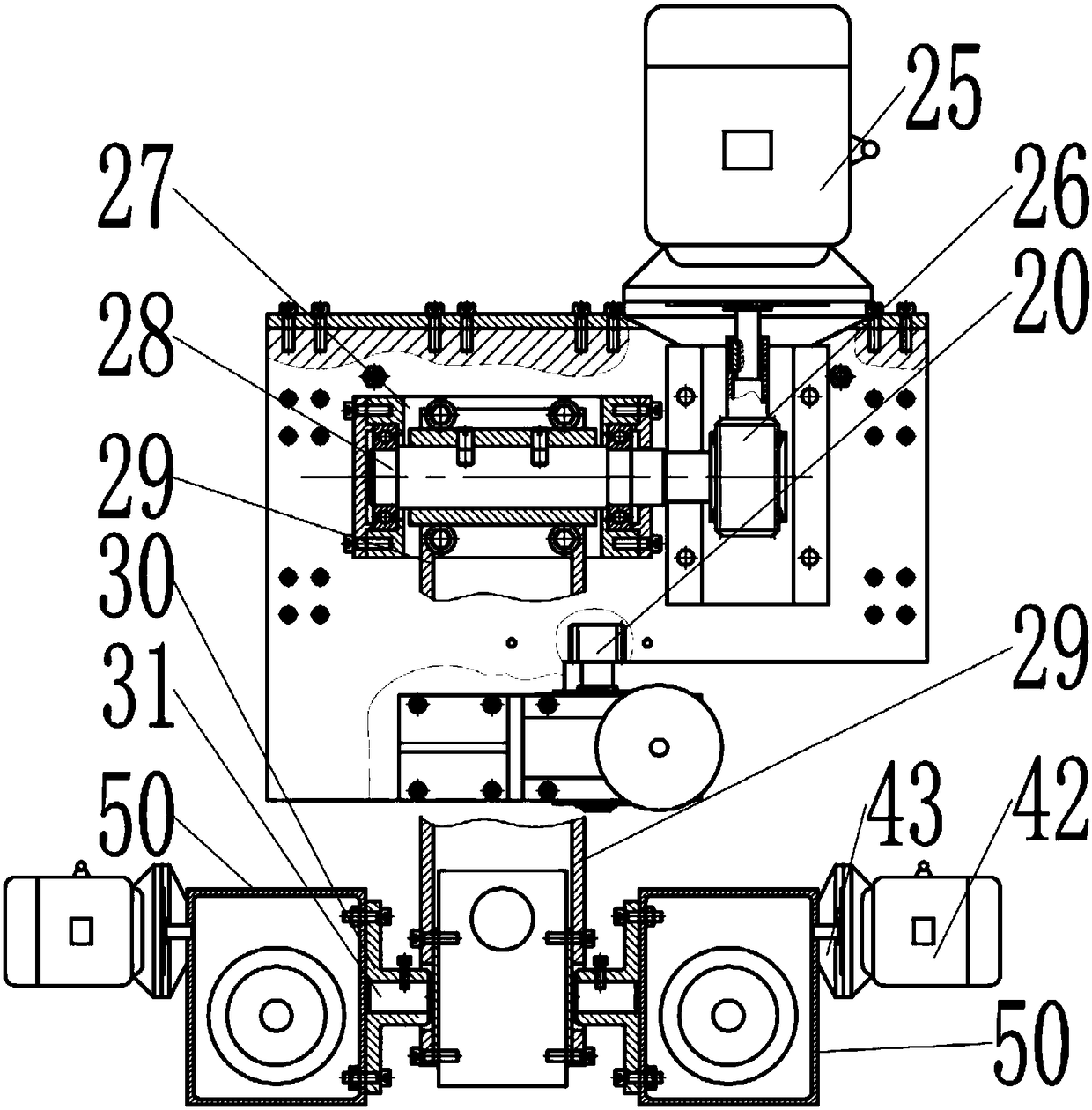

[0036] The rail support device 2 of the present invention includes a transmission device connected to the frame, a servo motor 25 connected to the transmission device, a swing arm 29 connected to the transmission device, and a cage 50 connected to the swing arm 29 .

[0037] Wherein, the transmission device can include a driving gear driven by the servo motor 25, a driven ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com