Area adjustable forming platform and method applied to 3D printer forming cylinder

A technology of 3D printers and forming cylinders, which is applied in the field of area-adjustable forming platforms, can solve the problems of inflexible metal parts forming requirements, and achieve the effect of simple and easy technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

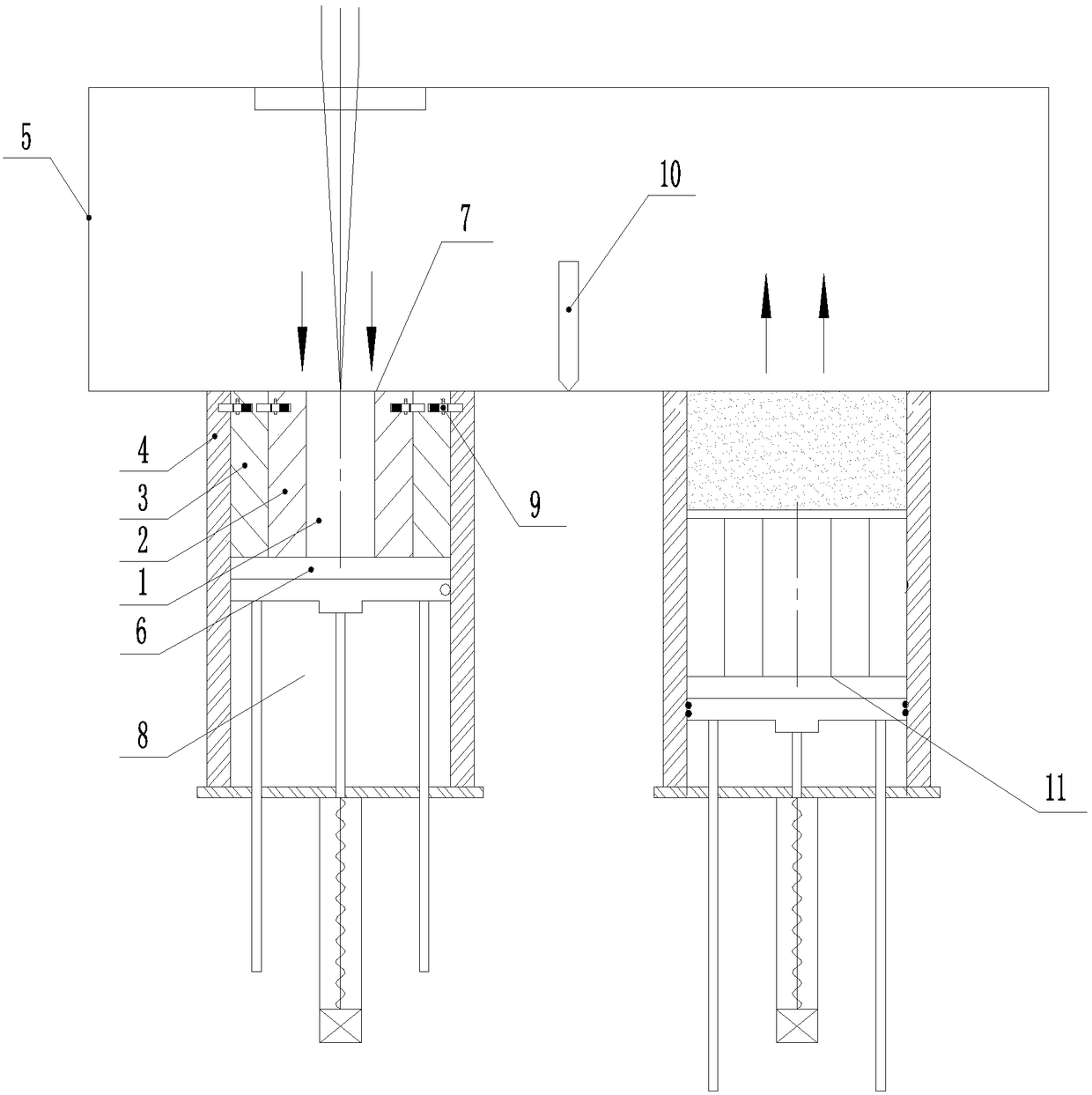

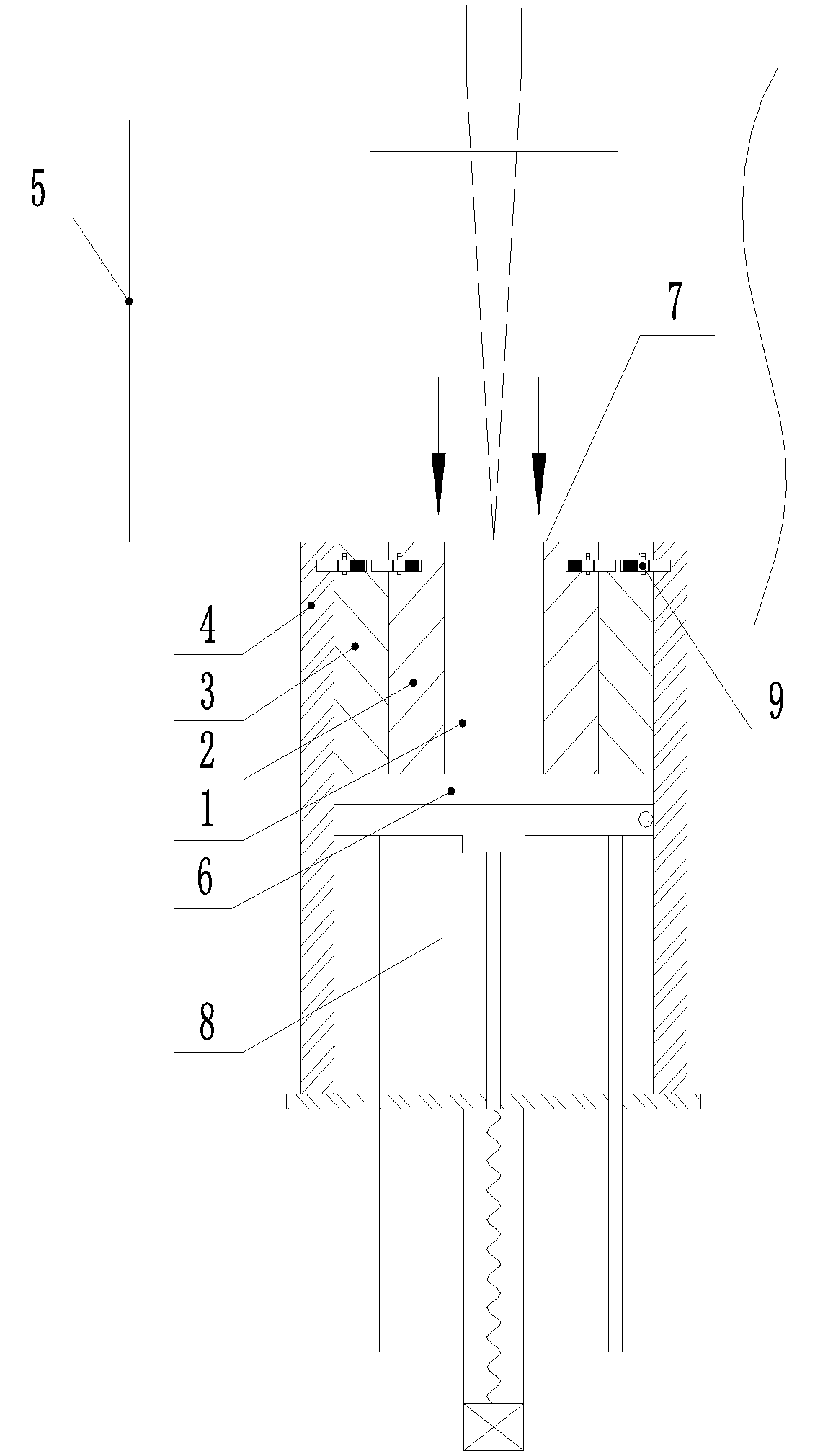

[0038] Such as Figure 1-6 shown. The invention discloses an area-adjustable molding platform applied to a molding cylinder of a 3D printer, comprising a molding chamber 5, a molding cylinder 4 placed below the molding chamber 5, a screw mechanism 8 carrying the molding platform to move up and down; powder spreading 10, Powder cylinder and its lifting mechanism 11;

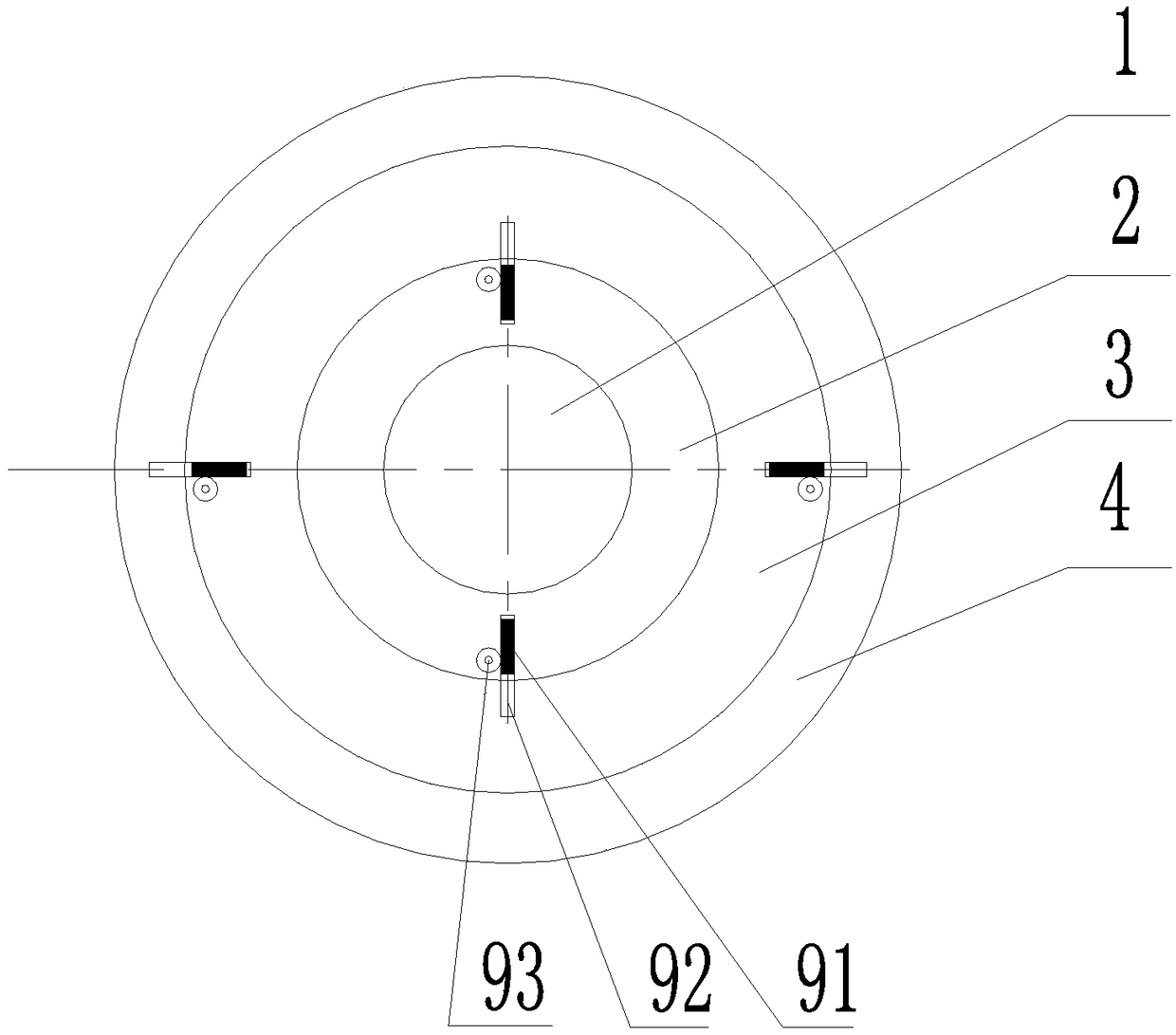

[0039] The forming platform includes: a first platform 1, a second platform 2 and a third platform 3 with equal heights and unequal diameters; the second platform 2 and the third platform 3 are hollow structures; The platform 1 is the center, and is nested in sequence according to the diameter and fits in a gap. They are placed on the adapter plate 6 connected with the screw mechanism 8; wherein, the first platform 1 is fixedly connected with the adapter plate 6;

[0040] At the radial contact positions between the forming cylinder 4, the second platform 2 and the third platform 3, there are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com