Multi-freedom degree self-adaption lifting obstacle crossing-type vehicle articulation mechanism

A technology of lifting and overcoming obstacles and hinged mechanism, which is applied to the steering mechanism, steering mechanism and vehicle parts of front and rear tandem vehicles, which can solve the problems of poor passability and large wheelbase, and achieve strong bearing capacity, low cost and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

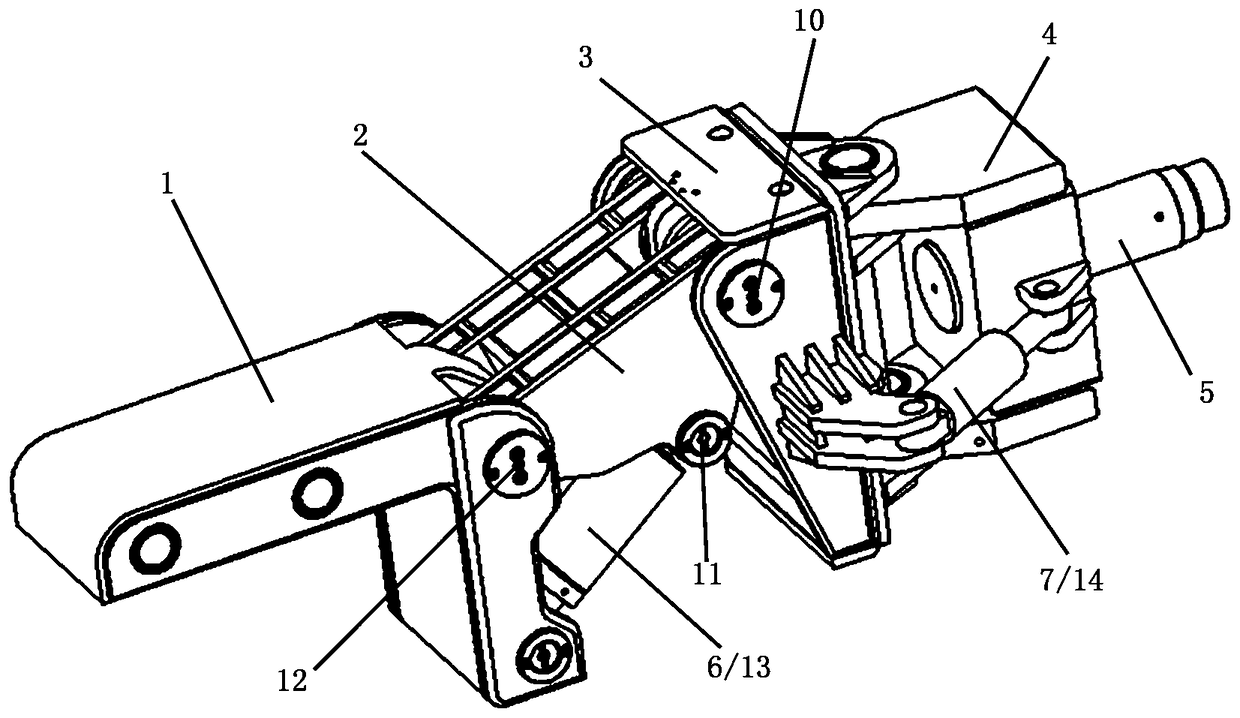

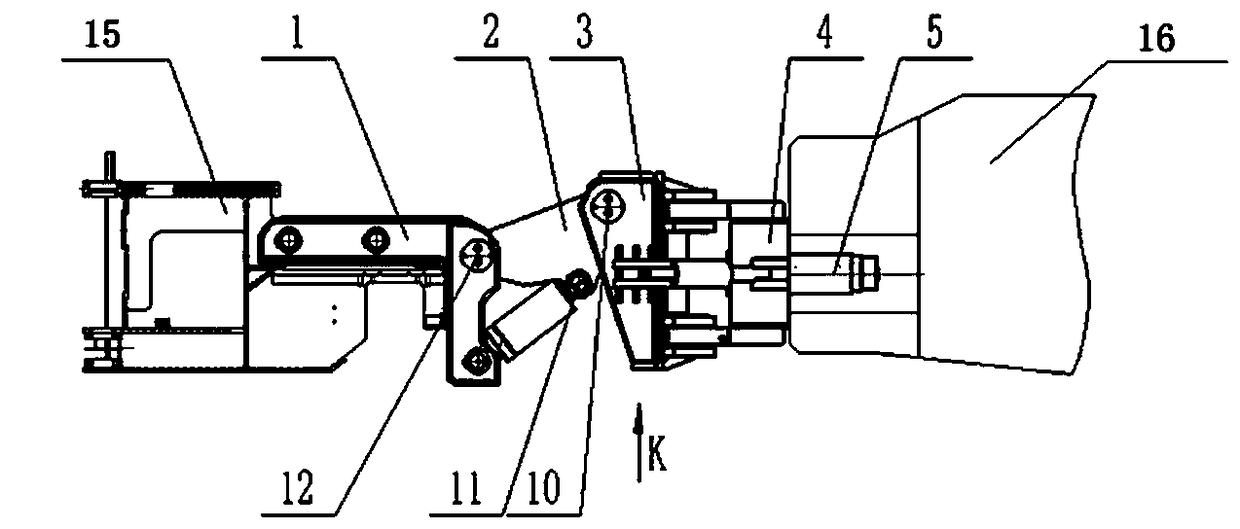

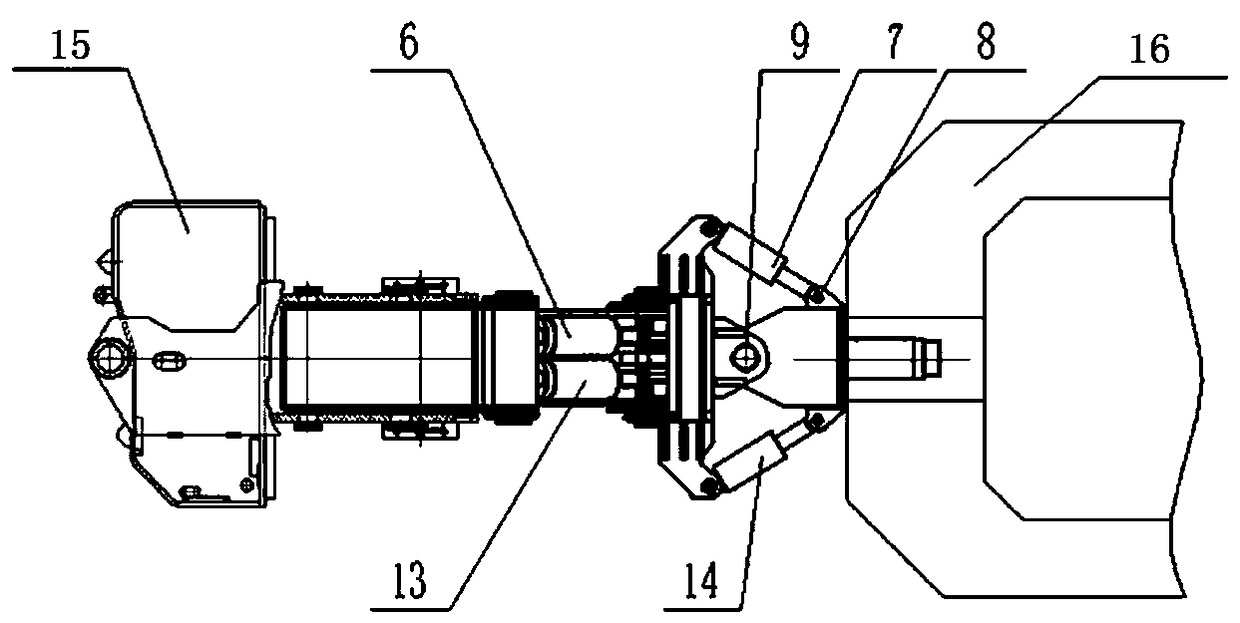

[0035] Such as figure 1 , 2 , the multi-degree-of-freedom self-adaptive lifting obstacle-crossing vehicle articulation mechanism shown in 3, including the front connection part 1, the triangular lifting arm 2, the steering joint part 3, the swing joint part 4, the swing shaft 5, the lifting cylinder I6, and the steering cylinder Ⅰ7, oil cylinder pin Ⅰ8, hinge pin Ⅰ9, hinge pin Ⅱ10, oil cylinder pin Ⅱ11, hinge pin Ⅲ12, lifting cylinder Ⅱ13, steering cylinder Ⅱ14. The front connecting part 1 is fixedly connected with the front frame through two sets of pin shafts. The front connecting part 1 is connected with the triangular lifting arm 2, the lifting cylinder I6, and the lifting cylinder II13 through the hinge pin III12 and the cylinder pin II11 to form a lifting mechanism. The triangular lifting arm 2 and the steering hinge part 3 are hinged horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com