A kind of synthetic method of low-solvent ternary copolymerization block silicone oil

A technology of ternary copolymerization block and synthesis method, which is applied in the direction of improved hand feeling fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of reducing solvent usage, easy demulsification, fabric hydrophobicity, etc. Roller, increase the effective content, improve the effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare the product of embodiment 1 according to the following steps:

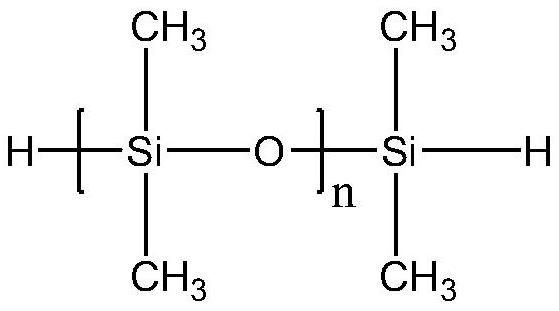

[0038] (1) Take 40 parts by mass of hydrogen-terminated silicone oil with a molecular weight of 13000 in a three-necked flask, stir and heat to 90°C,

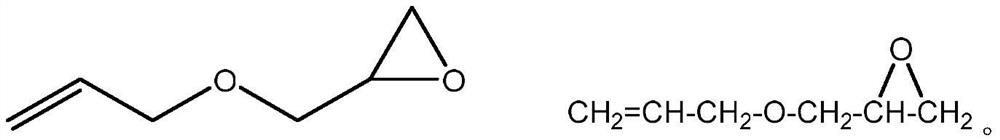

[0039] (2) Add 1 mass part of allyl glycidyl ether AGE and 0.04 mass part of chloroplatinic acid, heat and stir to keep the temperature at 115-126 ° C, and react for 2 hours,

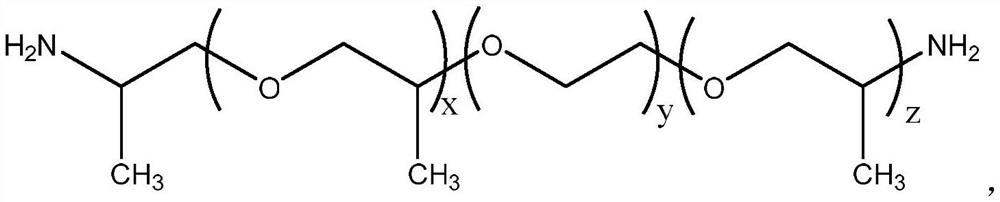

[0040] (3) Add 16 parts by mass of polyetheramine ED-2003, and at the same time add 16 parts by mass of 2-methyl-2,4-pentanediol and 32 parts by mass of ethylene glycol monobutyl ether at 140-150°C After reacting for 6 hours, adjust the pH to 6-7 with glacial acetic acid to obtain the finished block silicone oil.

Embodiment 2

[0042] Prepare the product of embodiment 2 according to the following steps:

[0043] (1) Take 35 parts by mass of hydrogen-terminated silicone oil with a molecular weight of 15000, stir and heat it to 90°C in a three-necked flask,

[0044] (2) Add 1 mass part of allyl glycidyl ether AGE and 0.035 mass part of chloroplatinic acid, heat and stir to keep the temperature at 115-126 ° C, and react for 2 hours,

[0045] (3) Add 12.25 parts by mass of polyetheramine ED-2003, and at the same time add 14 parts by mass of 2-methyl-2,4-pentanediol and 28 parts by mass of ethylene glycol monobutyl ether at 140-150°C After reacting for 6 hours, adjust the pH to 6-7 with glacial acetic acid to obtain the finished block silicone oil.

Embodiment 3

[0047] The product of embodiment 3 is prepared according to the following steps:

[0048] (1) Take 40 parts by mass of hydrogen-terminated silicone oil with a molecular weight of 13000 in a three-necked flask, stir and heat to 90°C,

[0049] (2) Add 1 mass part of allyl glycidyl ether AGE and 0.04 mass part of chloroplatinic acid, heat and stir to keep the temperature at 115-126 ° C, and react for 2 hours,

[0050] (3) Add 16 parts by mass of polyetheramine ED-2003, and at the same time add 20 parts by mass of 2-methyl-2,4-pentanediol and 28 parts by mass of ethylene glycol monobutyl ether at 140-150°C After reacting for 6 hours, adjust the pH to 6-7 with glacial acetic acid to obtain the finished block silicone oil.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap