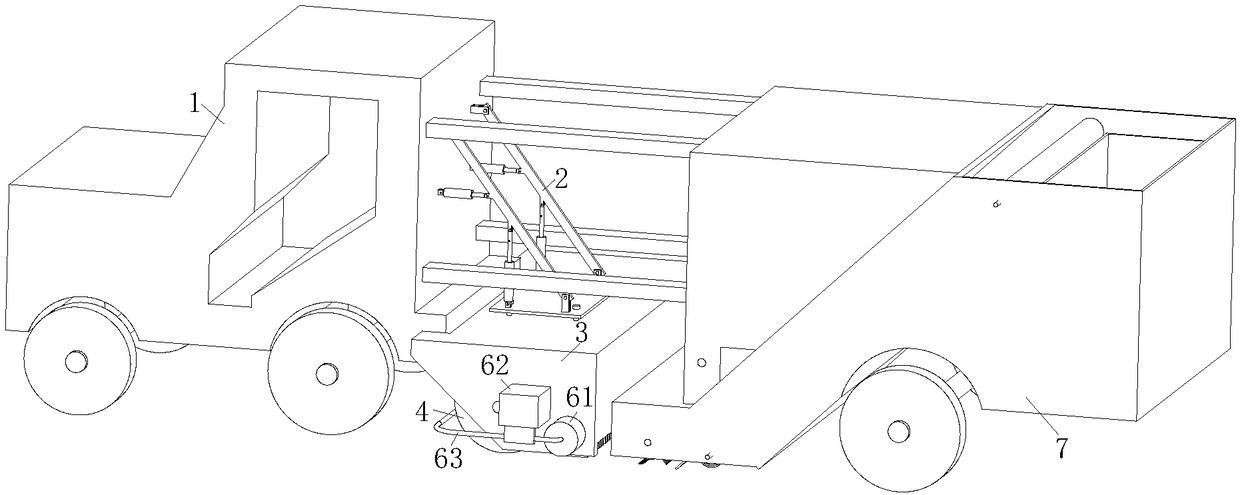

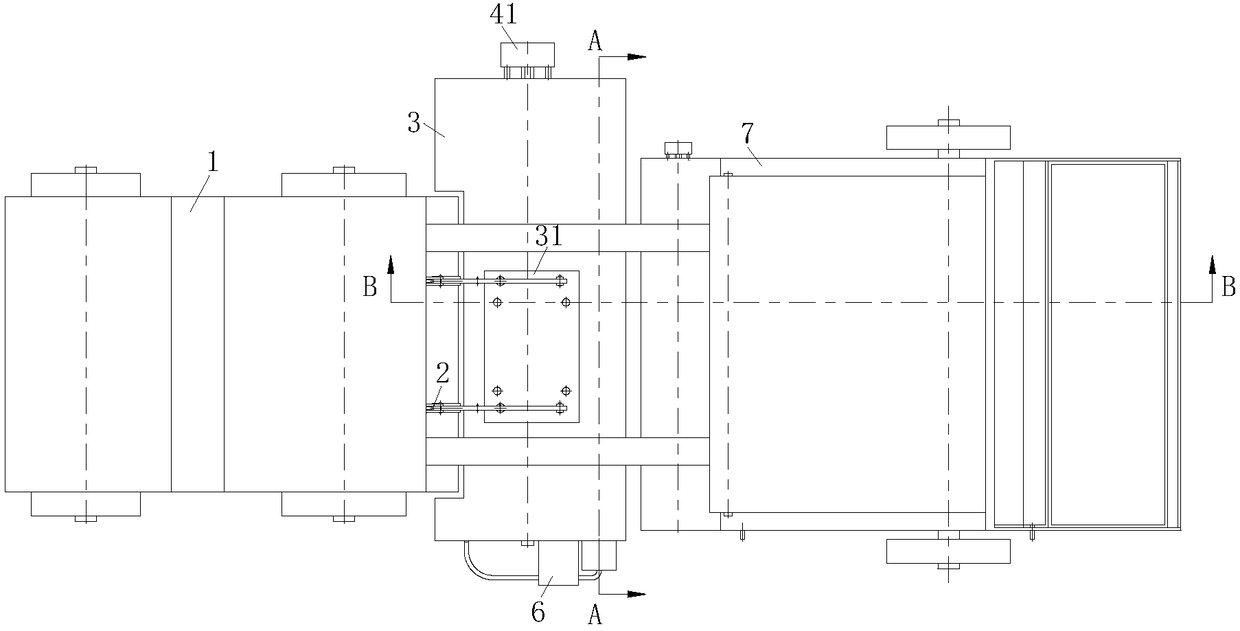

Crushing and recycling vehicle for old concrete pavement

A technology of old cement and crushing box, which is applied in the field of old cement pavement crushing and recycling vehicles, which can solve the problems of low work efficiency, dust generation, high labor intensity, etc., and achieve the effects of improving service life, reducing impact and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

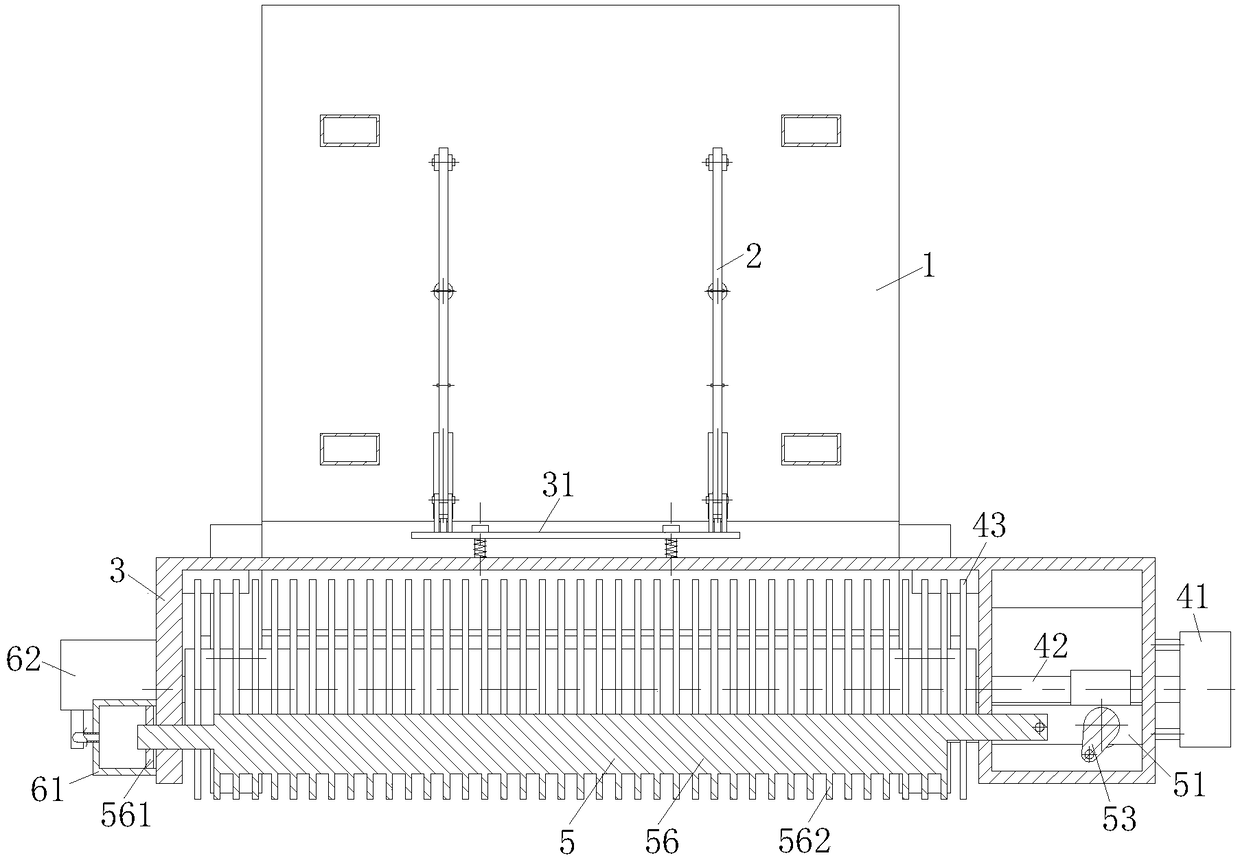

[0040] As an embodiment of the present invention, the crushing unit 5 includes a mounting plate 51, a drive shaft 52, a turbine 53, a cam 54, a connecting rod 55 and a crushing rod 56; the mounting plate 51 is installed inside the crushing box 3, so The transmission shaft 52 is rotated on the mounting plate 51, and one end of the transmission shaft 52 is provided with a turbine 53, and the turbine 53 cooperates with the helical teeth provided on the rotation shaft 42 to realize the rotation of the transmission shaft 52; the other end of the transmission shaft 52 is fixedly connected Cam 54; one side of the cam 54 is rotatably connected to one side of the connecting rod 55, and the other side of the connecting rod 55 is rotatably connected to the crushing rod 56, and the crushing rod 56 is embedded in the cutting gap formed by the cutting unit 4; The transmission shaft 52, the turbine 53, the cam 54 and the connecting rod 55 cooperate to realize the horizontal reciprocating move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com