Multi-functional steel-aluminum composite door window system

A steel-aluminum composite, multi-functional technology, applied in windows/doors, wing sash frames, building components, etc., can solve the problems that steel non-insulated doors and windows cannot meet fire prevention and heat insulation at the same time, high cost, complex design, etc. To achieve the effect of beautiful appearance, environmentally friendly materials, and various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

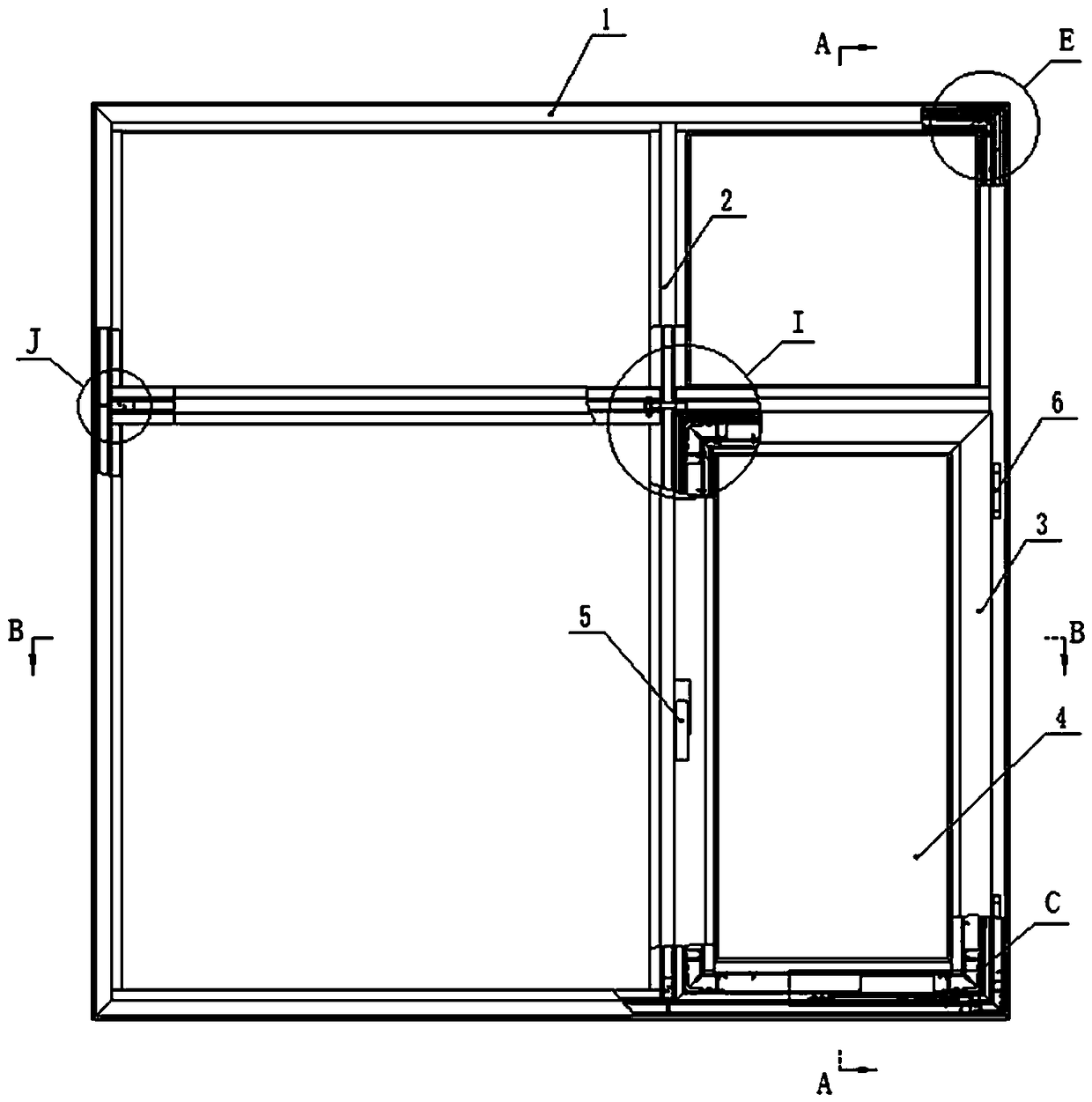

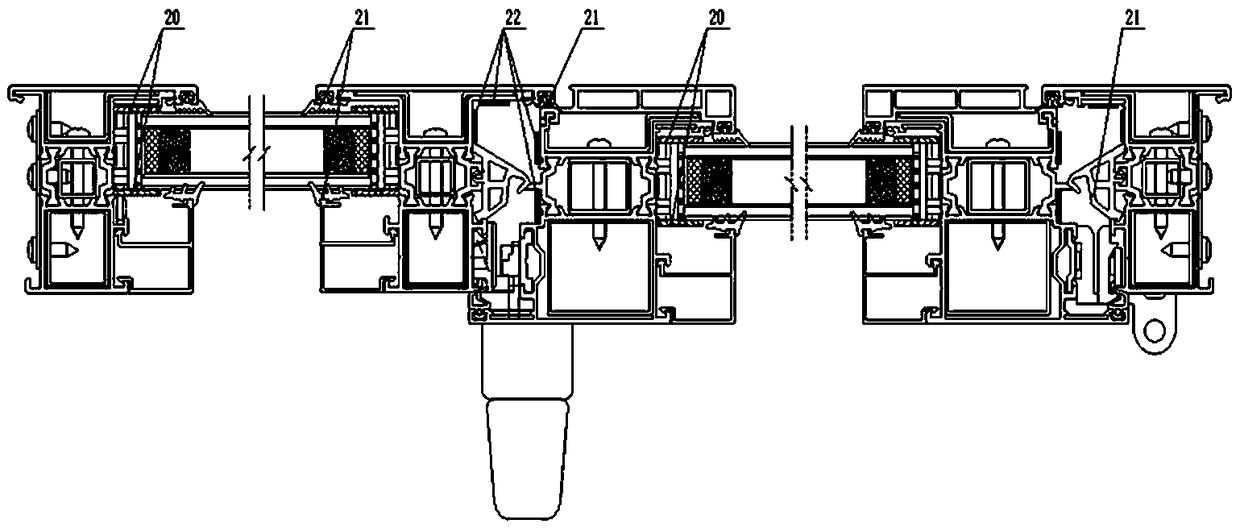

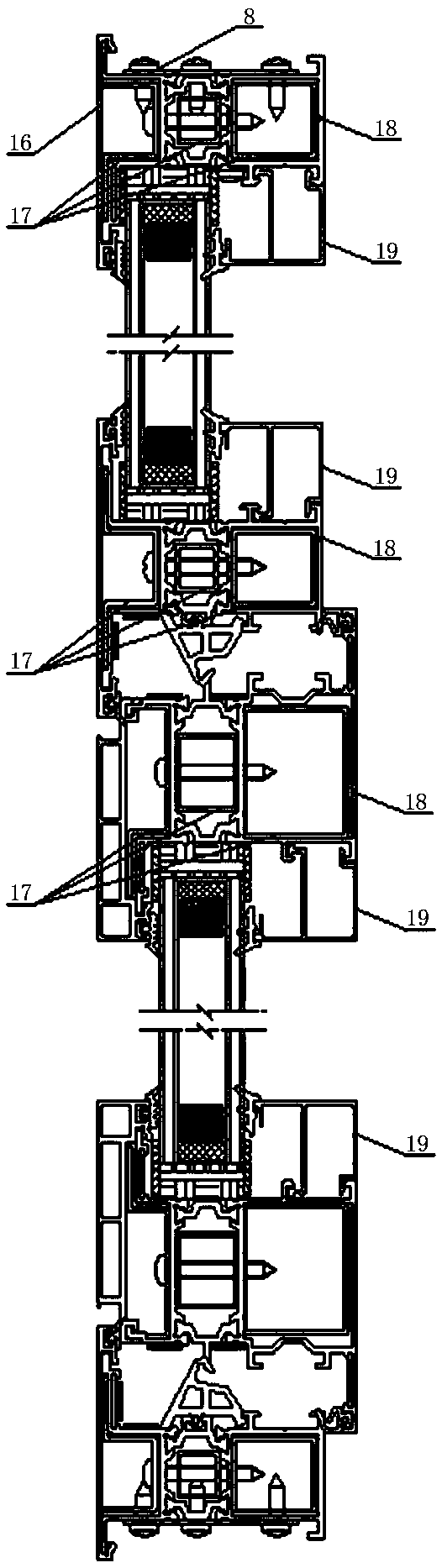

[0033] A multifunctional steel-aluminum composite door and window system, including a window frame 1, a middle stile 2, a sash frame 3, and matching glass 4, a lock 5, and a hinge 6. The window frame 1 and the sash frame 3 are connected by hinges. The window frame profile, The middle sash profile and the window sash frame profile include the broken bridge aluminum profile 18 and the steel frame 17. After the steel frame 17 is penetrated into the cavity of the broken bridge aluminum profile 18, the entire row of fixing screws is fixed on the upper surface of the steel frame 17 , And finally penetrate the surface decorative aluminum profile 16 to form a steel-aluminum composite profile. The stile connector at the cross of the stile is connected by the stile tie rod 11 and the eccentric screw 12, and the stile connector is locked by adjusting the eccentric screw 12. Then screw the lock nut 13 on the eccentric screw 12.

[0034] In the above-mentioned multifunctional steel-aluminum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com