A Reinforcement Method for Partition Rock Pillars in Shallow-Buried Small-Space Tunnels in Urban Areas

A small clear distance, shallow burial technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of large surface deformation and loss, and achieve the goals of controlling ground uplift and settlement, reducing impact, and improving strength and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

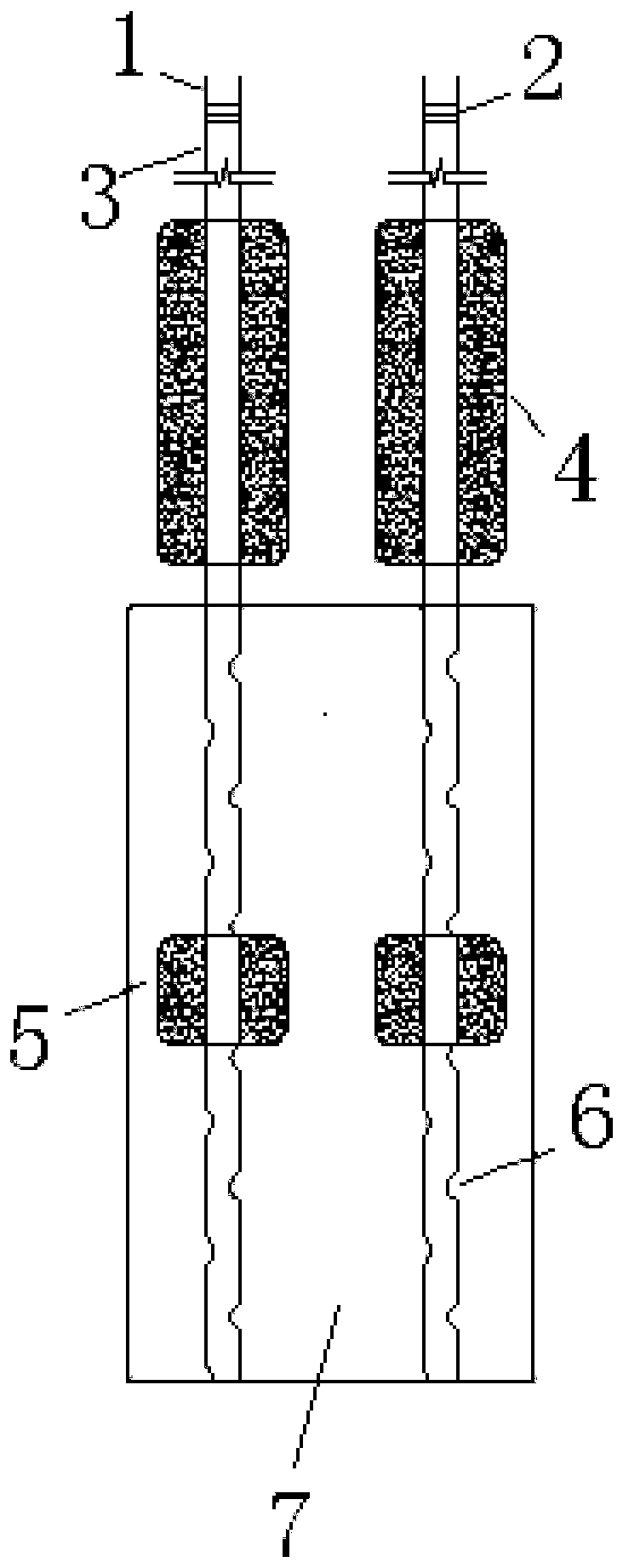

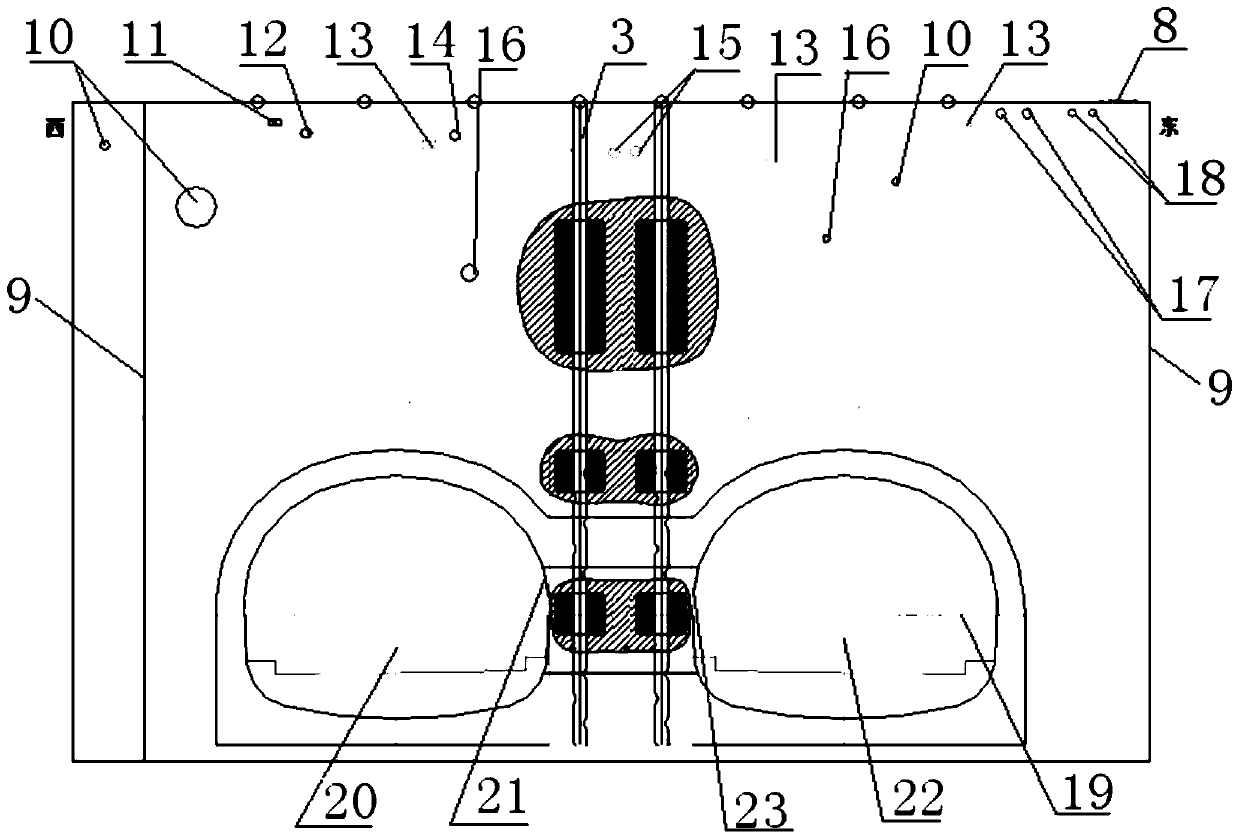

[0035] A method for reinforcing a partitioned rock pillar in an urban shallow-buried tunnel with a small clear distance, comprising the following steps:

[0036] (1) According to the width of the septum rock pillar and the stratum conditions, two rows of grouting holes are designed on the ground surface, and construction and drilling are carried out on the surface of the grouting holes; the construction drilling sequence is in accordance with the order of jumping holes in every row, and odd numbers are performed first. Drill holes in rows, and then use even rows of drilled holes as inspection holes or supplementary grouting holes according to the actual situation; the interval between rows of grouting holes is 1m.

[0037] (2) Combining the grouting design requirements and the depth of the target area, design and process the grouting pipe, make a round hole on the grouting pipe with reference to the grouting reinforcement target area, and bind the expansion mold bag at the same...

Embodiment 2

[0043] A method for reinforcing a partitioned rock pillar in a shallow-buried urban tunnel with a small clear distance, the steps of which are as described in Example 1, except that in step (1), the interval between rows of grouting holes is 2m.

Embodiment 3

[0045] A method for strengthening the middle rock pillar of an urban shallow-buried small-space tunnel, the steps of which are as described in Example 1, the difference being that in step (2), the grouting pipe is tied to the expansion mold bag in the first-level pressure isolation zone. Drill a round hole at the position, and inject liquid into the mold bag through the round hole; drill round holes at intervals along the axial direction of the grouting pipe on the grouting pipe located in the reinforcement area of the septum rock pillar; the diameter of the round hole is 10mm, located in the reinforcement area of the septum rock pillar The distance between the round holes on the grouting pipe is 20cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com