Nozzle structure with azimuth angle for radial direction pre-swirling system

A technology of pre-swirl nozzle and pre-swirl system, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of poor cooling airflow, insufficient air supply flow, affecting stability, etc., and reduce pressure loss. , large air-conditioning flow, the effect of alleviating the temperature level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

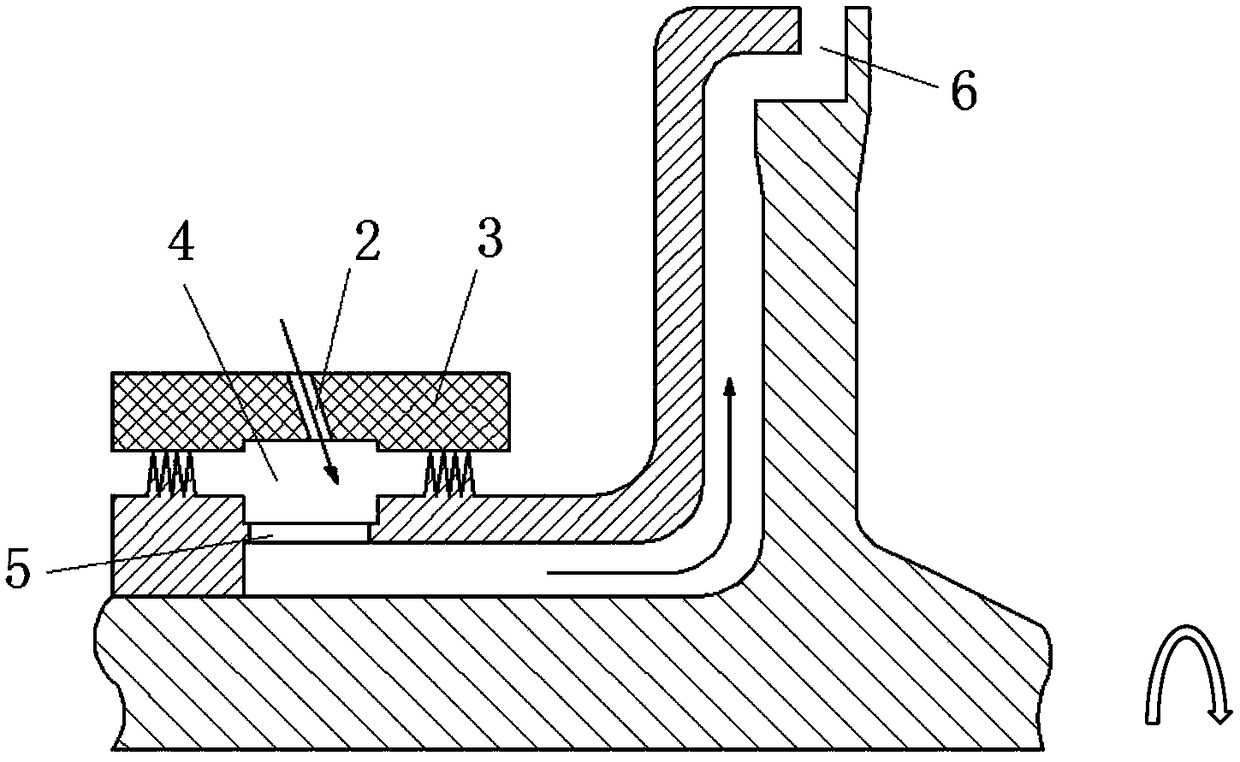

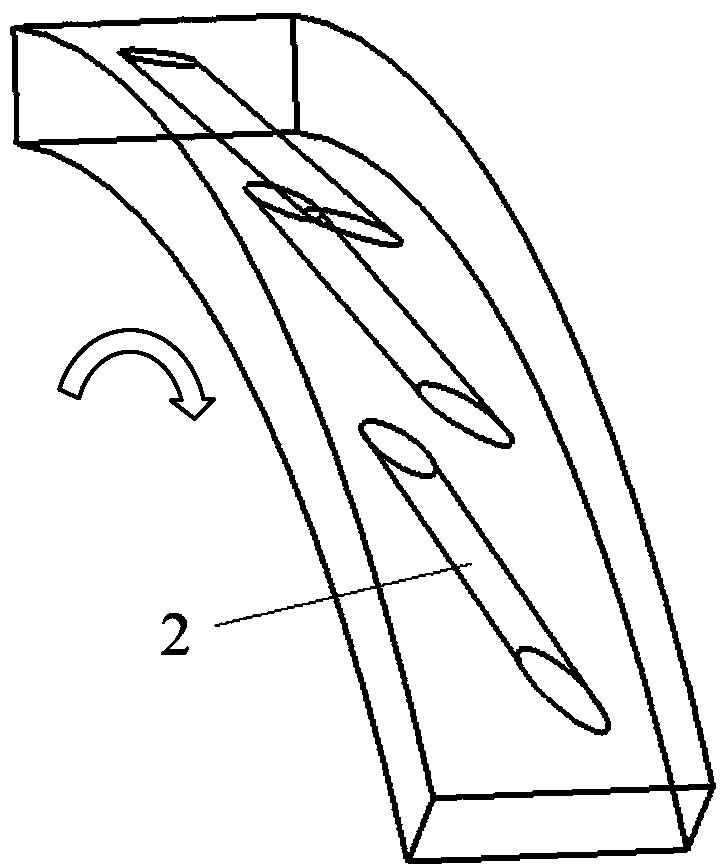

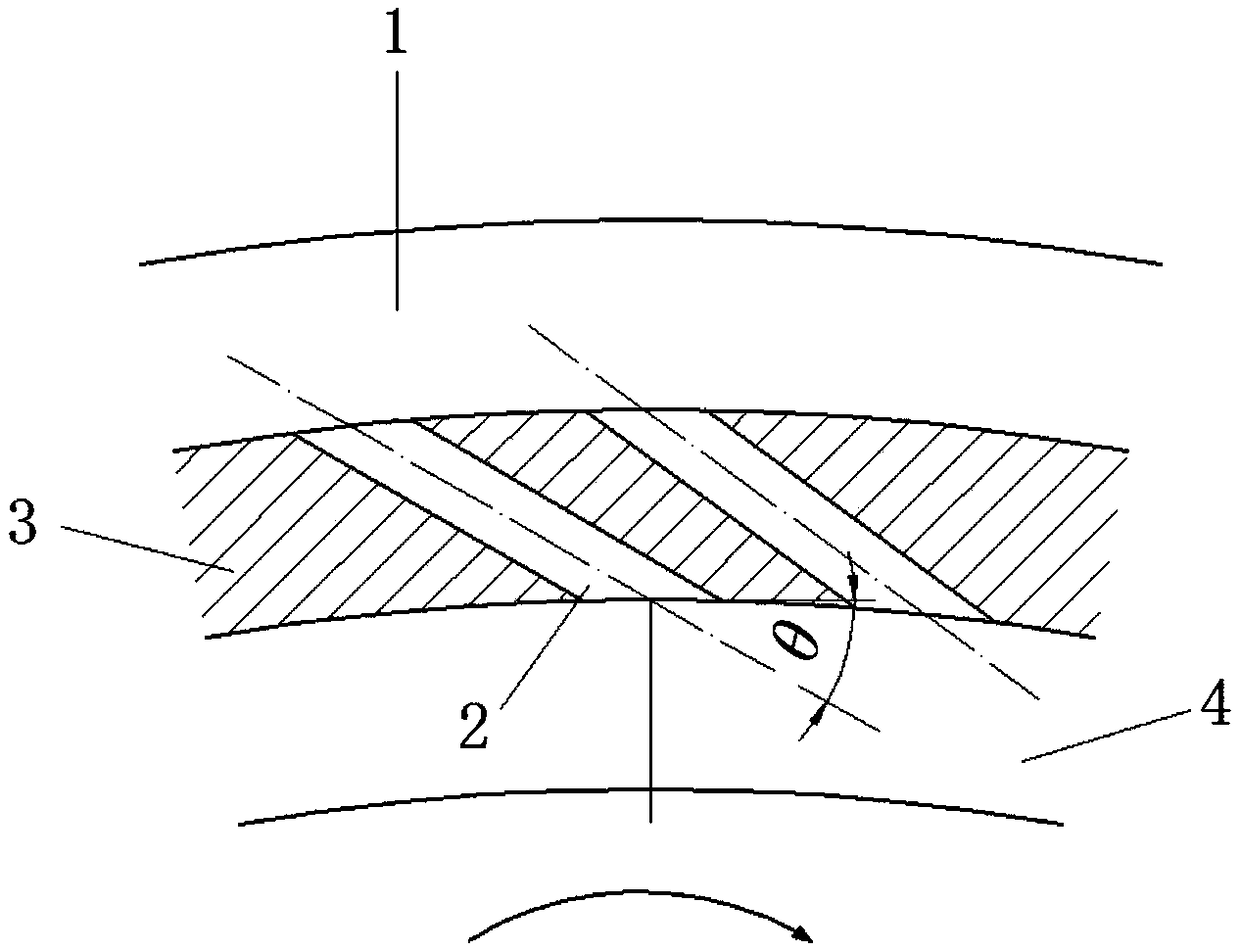

[0024] This embodiment is a nozzle structure with an azimuth angle in the radial pre-swirl system of aero-engine and ground gas turbine. The azimuth angle of the pre-swirl nozzle 2 is controlled by two angles, θ and α, where θ is the pre-swirl angle of the pre-swirl nozzle, and α is the off-angle of the axis of the pre-swirl nozzle in the axial direction. The above structure will be further described below with reference to the accompanying drawings.

[0025] like figure 1 As shown in the figure, in the radial pre-swirl system, the high-pressure cooling mainstream gas is drawn from the compressor and reaches the intake chamber 1, and then enters the pre-swirl nozzle 2 for expansion and acceleration, as shown in the figure figure 2 As shown in the figure, the inlet and outlet of the pre-swirl nozzle 2 are located on the annular surface of the static disk and are evenly arranged along the circumferential direction. The projection angle on the nozzle is the pre-swirl angle θ of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com