Piston type air compressor

An air compressor and piston technology, which is applied to liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of low efficiency of single-piston air compressors and inability to meet fuel cell systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

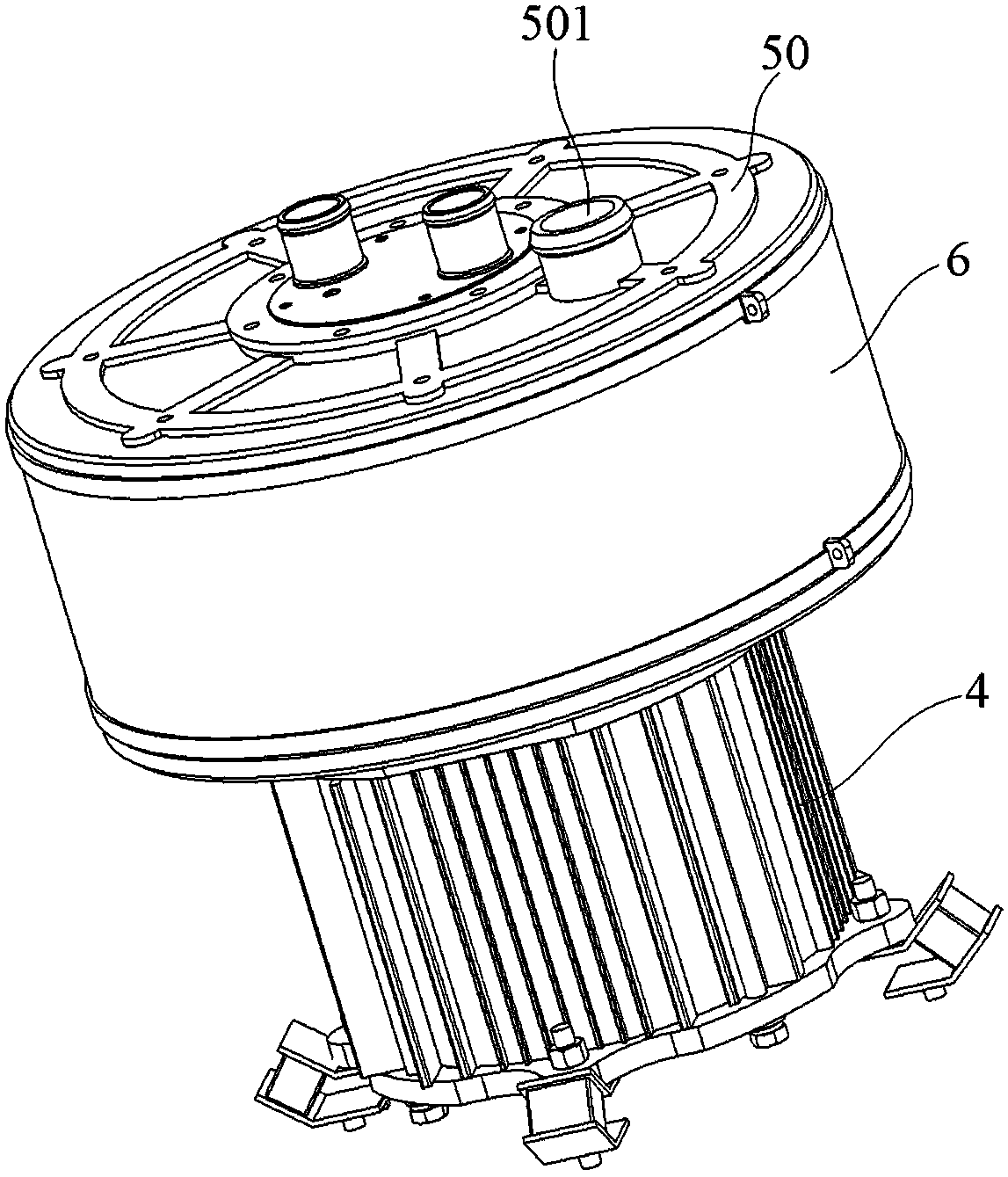

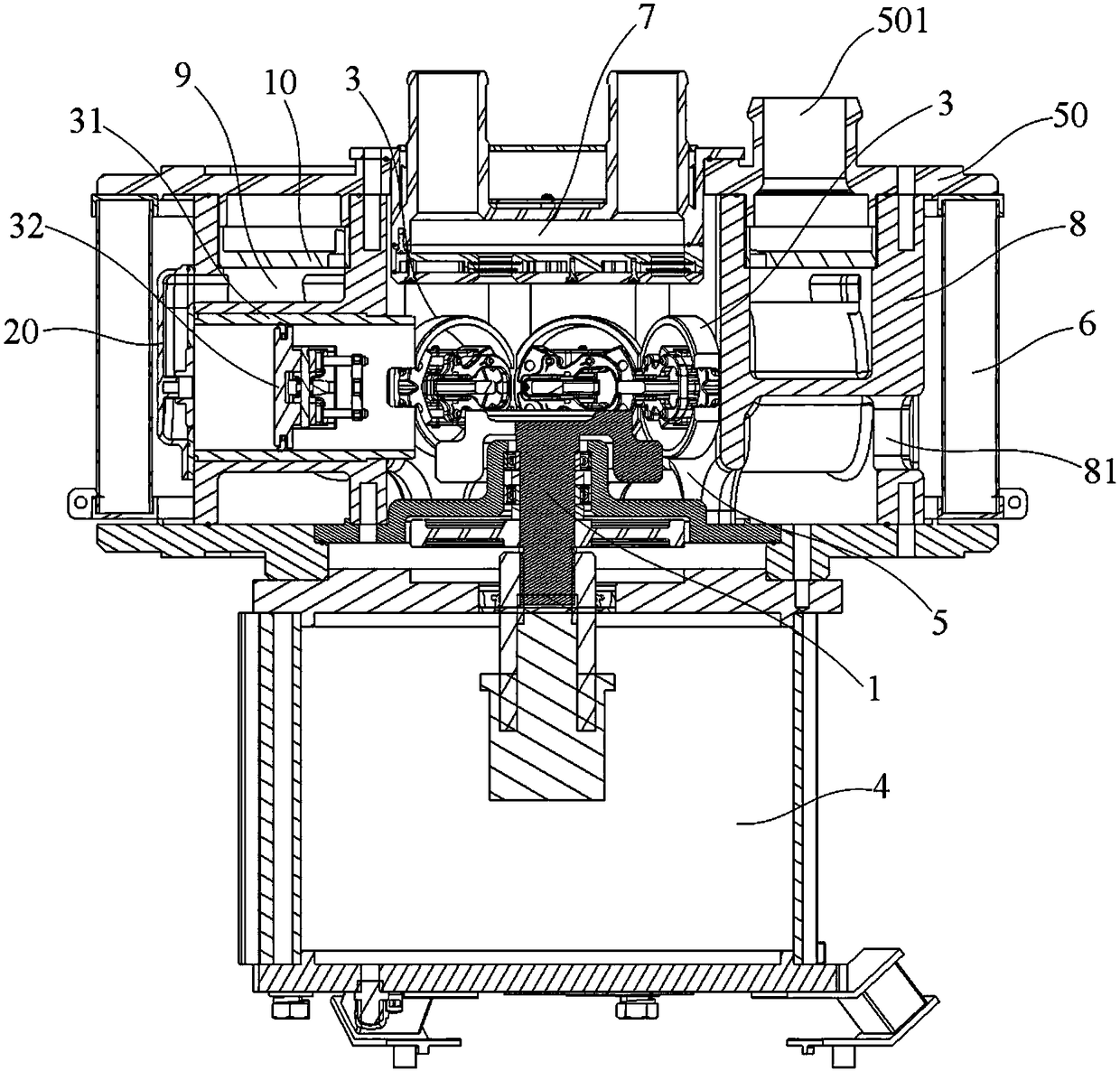

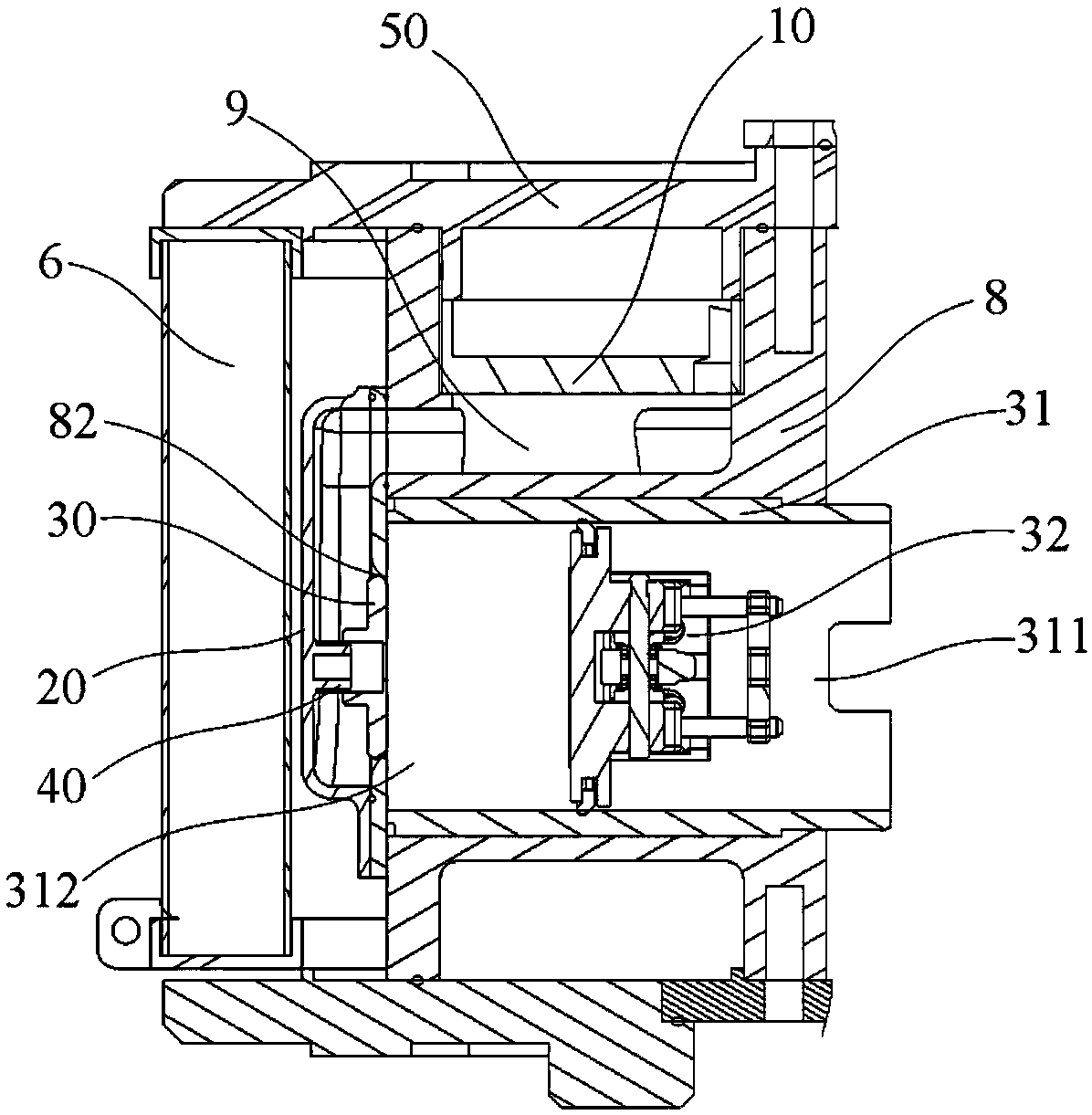

[0079] Such as Figure 1 to Figure 2 Shown is an embodiment of the piston air compressor of the present invention. The piston air compressor includes a main shaft 1, a driving part, an eccentric wheel 2 and a plurality of piston assemblies 3. The main shaft 1 rotates around the axis driven by the driving part; The axes of the main shaft 1 are parallel; a plurality of piston assemblies 3 are arranged around the circumference of the main shaft 1; Air port 312; the piston 32 is arranged in the cylinder body 31, one end of the connecting rod 33 is connected with the piston 32, and the other end of the connecting rod 33 is connected with the eccentric wheel 2; when the eccentric wheel 2 rotates, the connecting rod 33 drives the piston 32 in the cylinder The body 31 reciprocates.

[0080] The piston air compressor is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com