Potential energy recycling and motor speed regulation double pump hydraulic energy saving system

A technology of motor speed regulation and potential energy recovery, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of insufficient energy recovery, improved recovery efficiency, unfavorable machinery, etc., and achieve compact structure , Improve recovery efficiency and reduce working volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

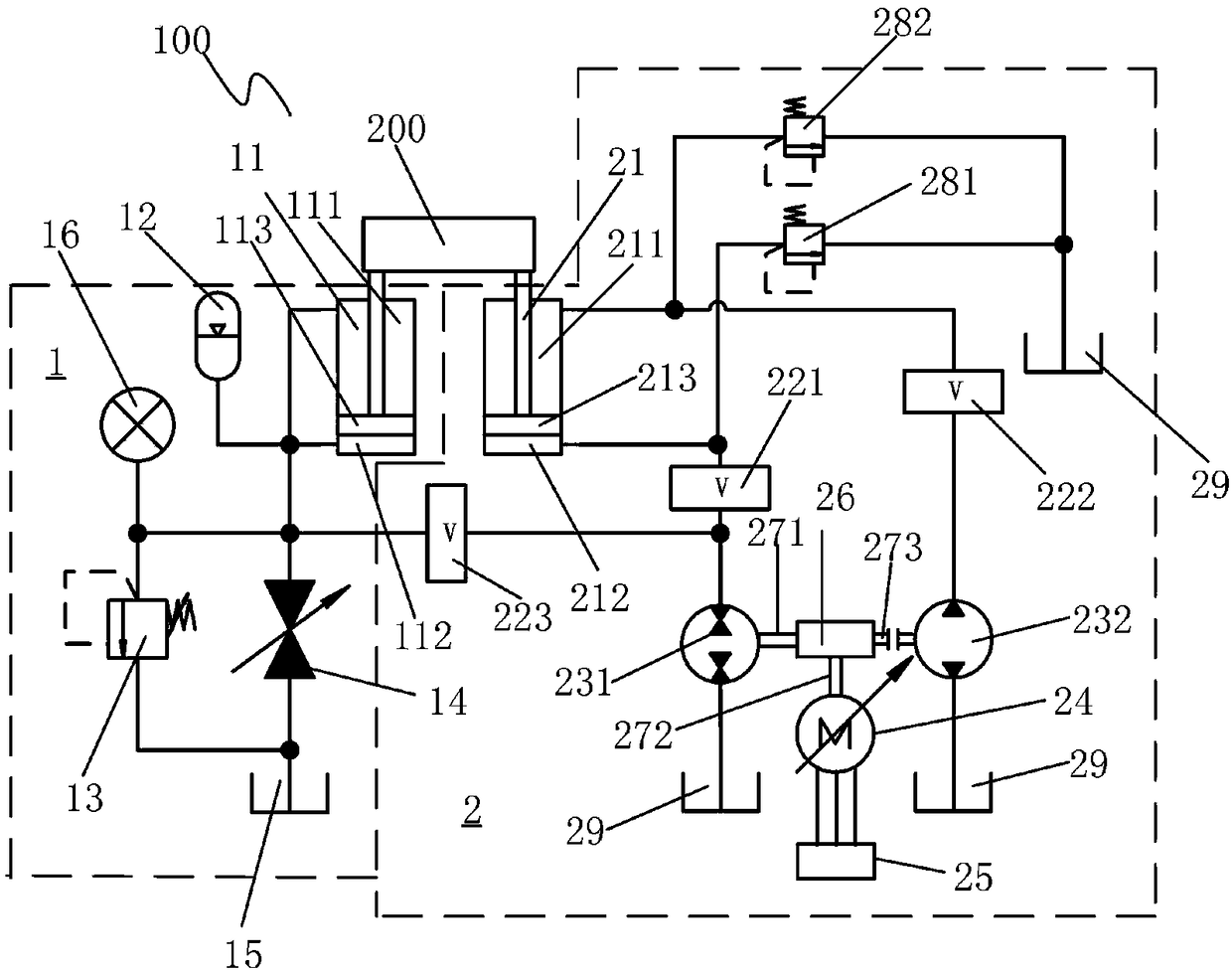

[0020] see figure 1 As shown, the double-pump hydraulic energy-saving system 100 of potential energy recovery and motor speed regulation of the present invention includes an energy recovery system 1 and a volumetric speed regulation control system 2;

[0021] The energy recovery system 1 includes an energy storage hydraulic cylinder 11 and an accumulator 12, a first safety valve 13, a shut-off valve 14, and an oil tank 15, and a pressure gauge 16; the energy storage hydraulic cylinder 11 can be a single-rod double-acting The hydraulic cylinder has an upper oil chamber 111 and a lower oil chamber 112 separated by a first piston 113, and the hydraulic effective area of the upper oil chamber 111 is smaller than the hydraulic effective area of the lower oil chamber 112, the upper oil chamber 111 and the lower oil chamber 112 The lower oil chamber 112 is connected to the accumulator 12; the upper oil chamber 111 and the lower oil chamber 112 are respectively connected to the fu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap