Dynamic balancing catcher

A technology of dynamic balancing and positioning disc, applied in the field of dynamic balancing, can solve the problems of affecting working time, complicated disassembly and installation, etc., and achieve the effect of reducing labor intensity, saving processing cost and material cost, and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

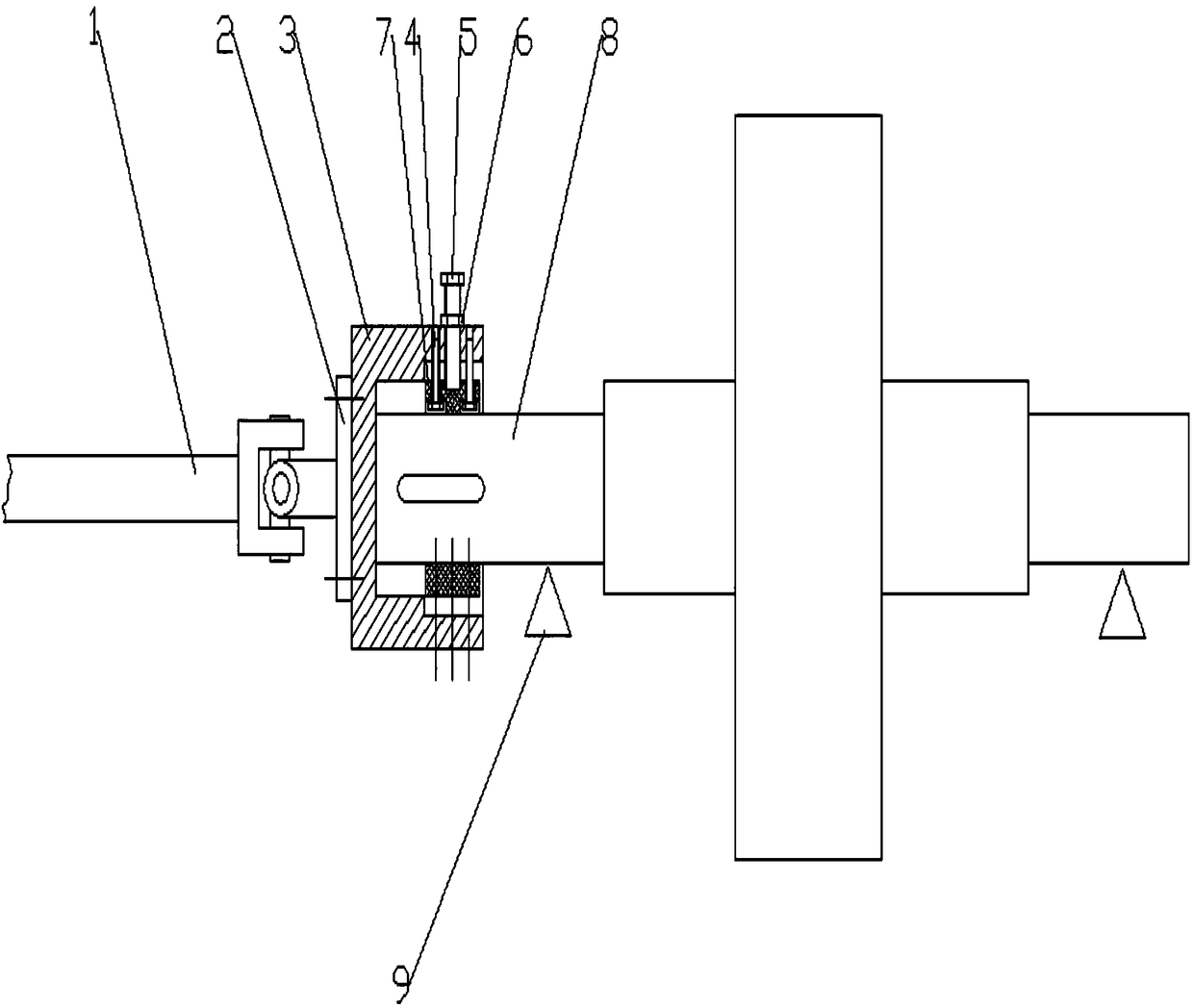

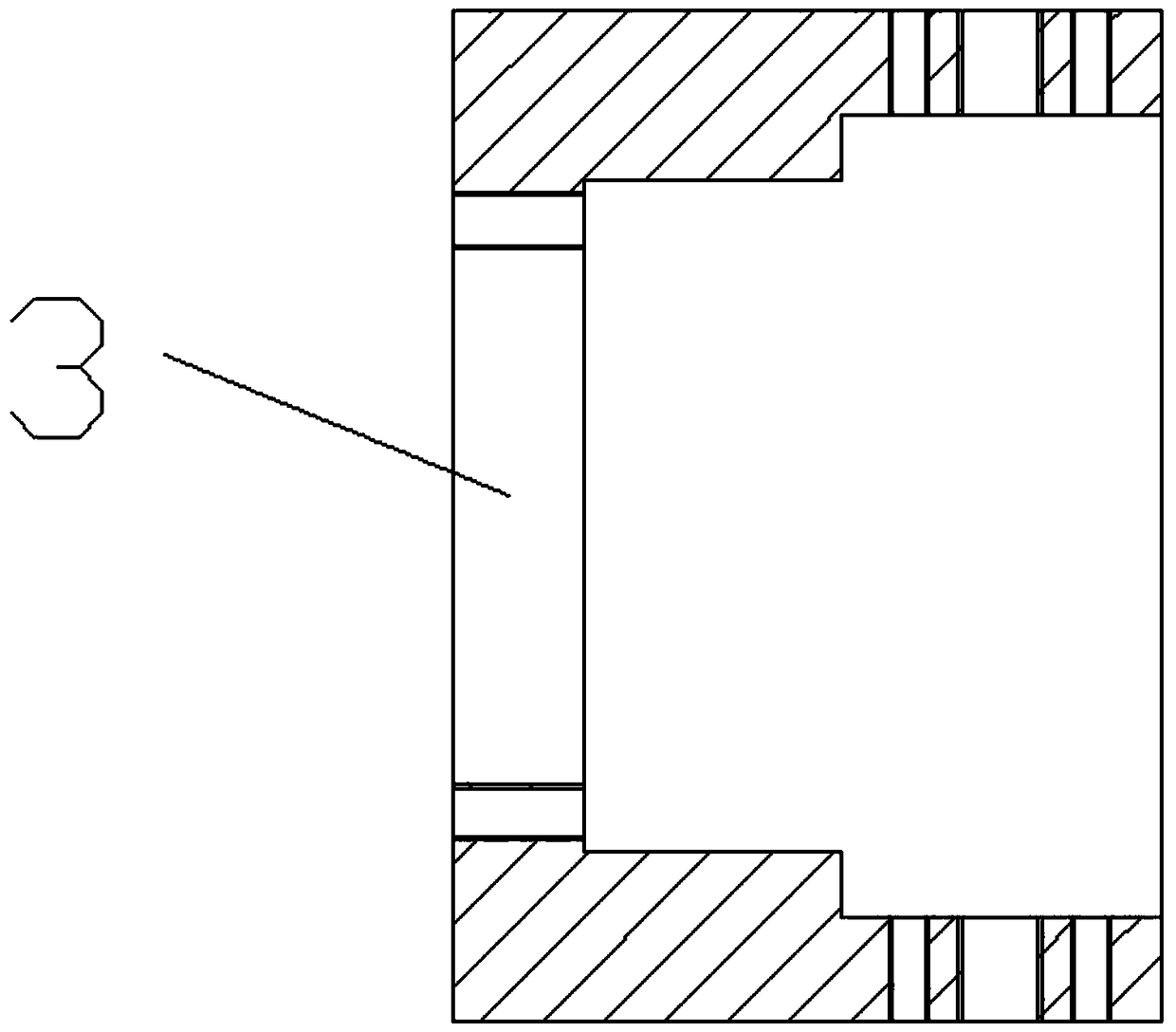

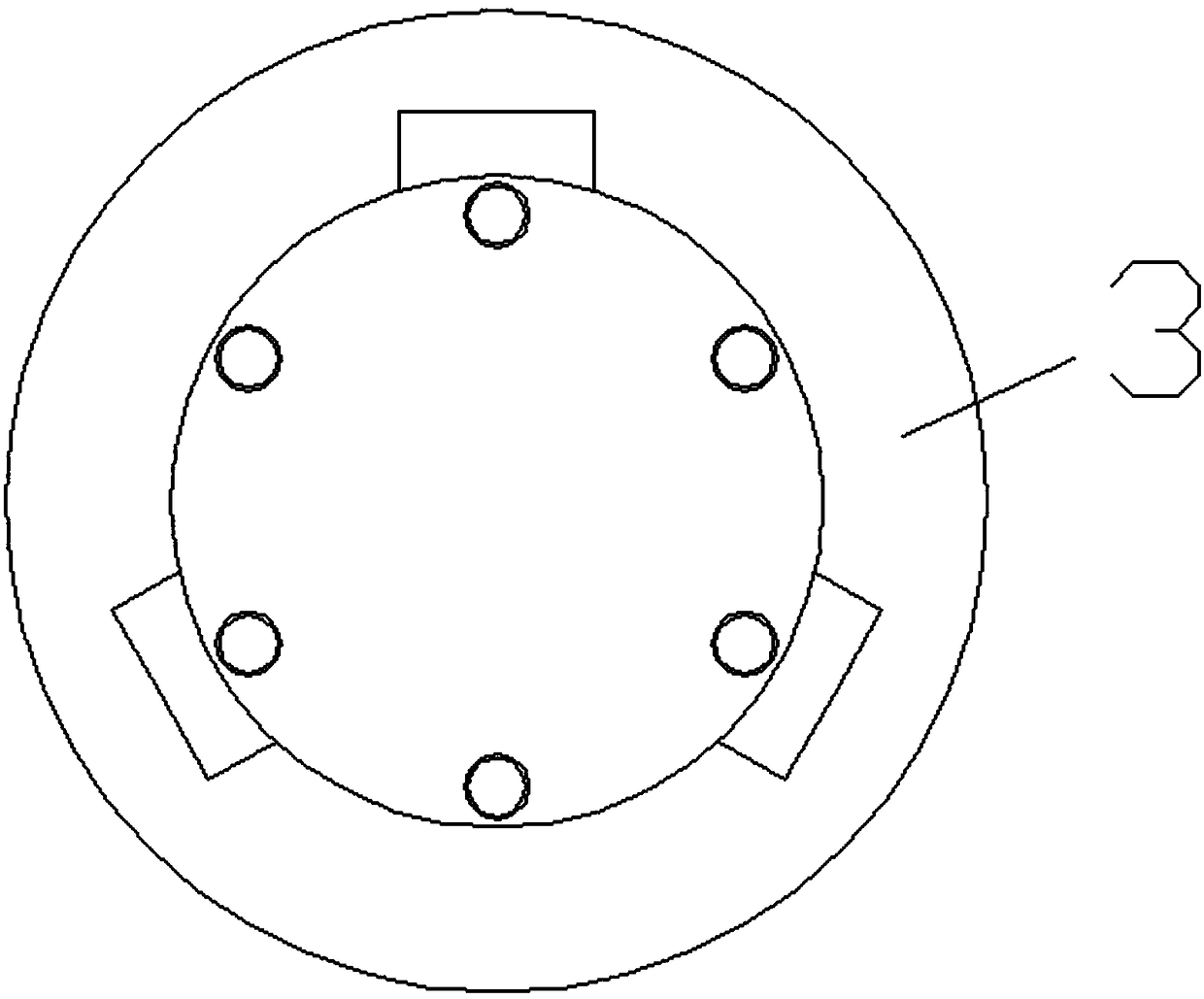

[0015] see Figure 1-Figure 5 , a dynamic balance joint provided by the embodiment of the present invention, the dynamic balance joint is used to connect the universal joint 1 and the experimental rotor 8 . The dynamic balancing handle includes a positioning plate 3, a positioning device (including a pad 7, a positioning screw 5, a nut 6 and two limit screws 4) and a small connecting plate 2. There are at least three positioning devices (three in the embodiment of the present invention). The small connecting disc 2 is fixed on one side of the positioning disc 3, and the universal joint 1 is fixed on the positioning disc 3 through the small connecting disc 2. The positioning disc 3 is cup-shaped, and the positioning disc 3 has a positioning hole, and the number of the positioning holes is consistent with the number of the positioning devices (there are three in the embodiment of the present invention). The three positioning holes are evenly distributed on the same circumferen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap