Cooling system of electric vehicle lithium battery

A technology for electric vehicles and heat dissipation systems, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as thermal runaway, poor temperature consistency of battery cells, and large resources, so as to reduce preheating links and maintain temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

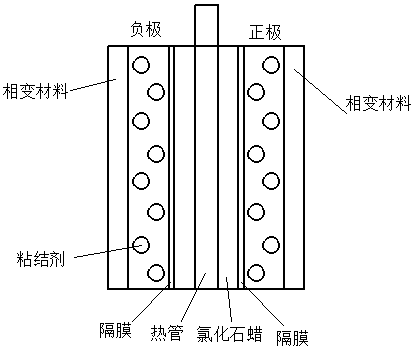

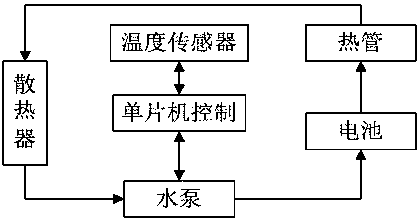

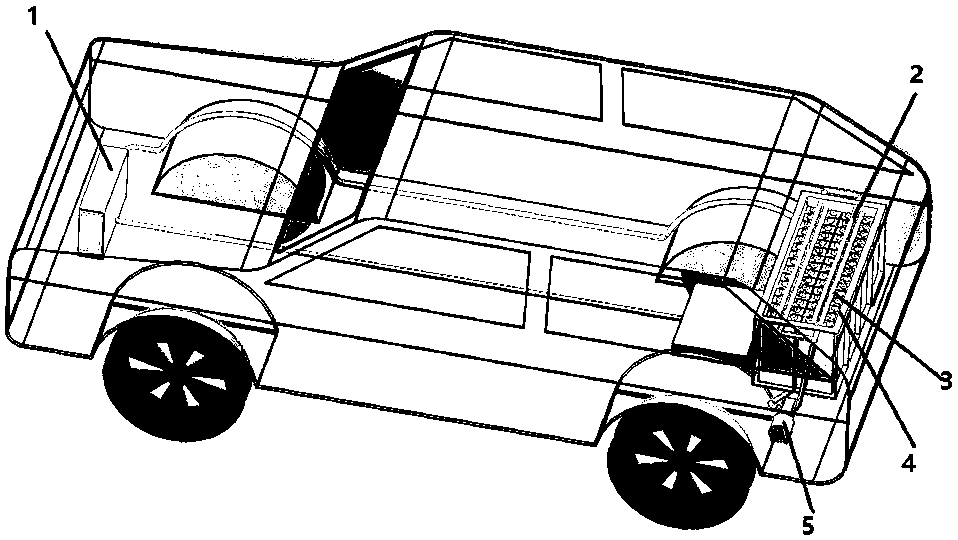

[0014] A heat dissipation system for a lithium battery of an electric vehicle according to the present invention comprises a lithium battery pack composed of a single lithium battery, and a water cooling system for dissipating heat as a whole for the lithium battery pack; The double-diaphragm layers of the positive and negative poles of the battery are filled with chlorinated paraffin, and a heat pipe is inserted in the middle of the double-diaphragm layer. The heat pipes of each single lithium battery protrude from one end of the single lithium battery and are connected to each other. Cooling system. The periphery of the single lithium battery is covered with a phase change material to absorb the heat released by the single lithium battery and store it in the form of latent heat; meanwhile, it can play a heat preservation effect in a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com