Novel board processing device

A sheet metal processing and equipment technology, applied in the field of sheet metal processing, can solve the problems of troublesome operation, random dripping of paint, easy dripping of paint on the ground or people, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

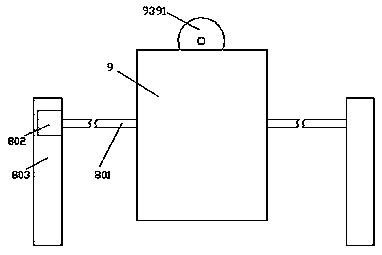

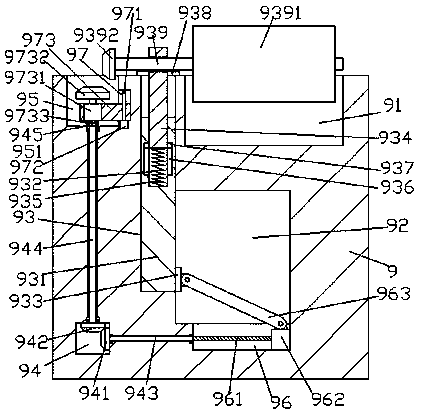

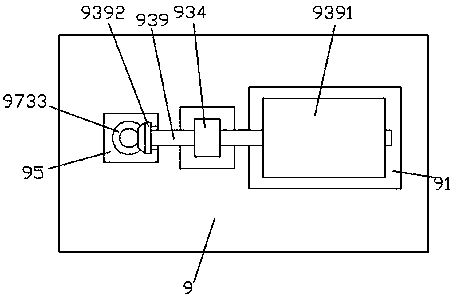

[0015] Such as Figure 1-Figure 4 As shown, a new type of plate processing equipment of the present invention includes a front and rear driving frame and a movable frame 9 movably installed on the front and rear driving frames. Shaped cavity 901, the front and rear driving frame includes a screw-shaped column 801 that is screw-fitted and installed in the screw-shaped cavity 901 and extends forward and backward. The plate 803 is rotated and installed, and the front part of the screw-shaped column 801 is extended and the end is installed in cooperation with the main driving machine 802. The outer surface of the main driving machine 802 is installed in the support plate 803, and the right side of the movable frame 9 A storage tank 91 is provided in the side top end surface, and a sinking groove 95 is provided in the left top end surface of the movable frame 9, and the movable frame 9 between the sinking groove 95 and the storage groove 91 The top end face is provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com