System and method for utilizing flue gas pyrolysis to perform pre-desulfurization and demercuration before combustion of high sulfur coal

A high-sulfur coal, pre-desulfurization technology, applied in the preparation/purification of sulfur, fuel, solid fuel, etc., can solve the problems of neglecting sulfur, fixed removal of mercury, etc., and achieve the effect of reducing treatment cost and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

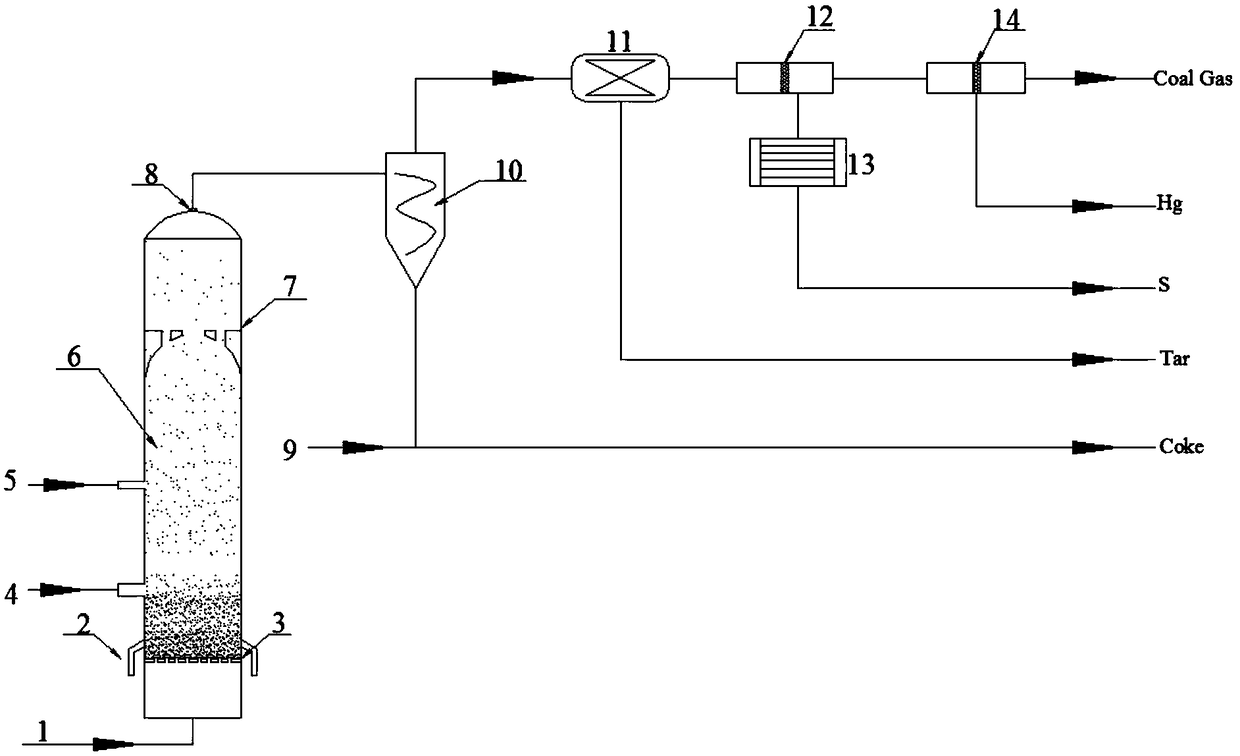

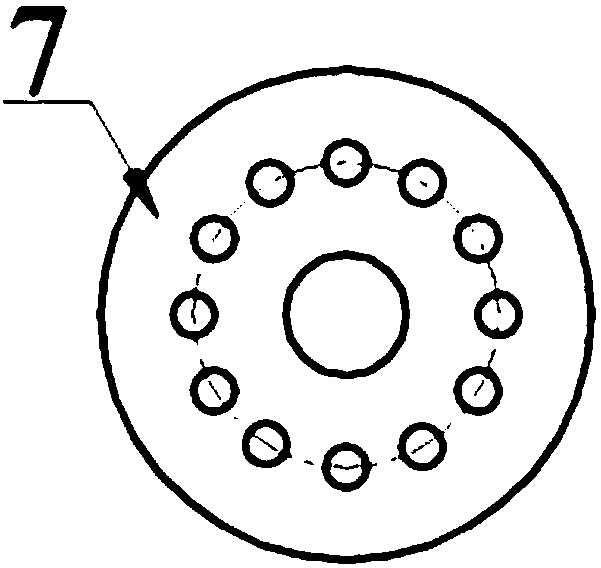

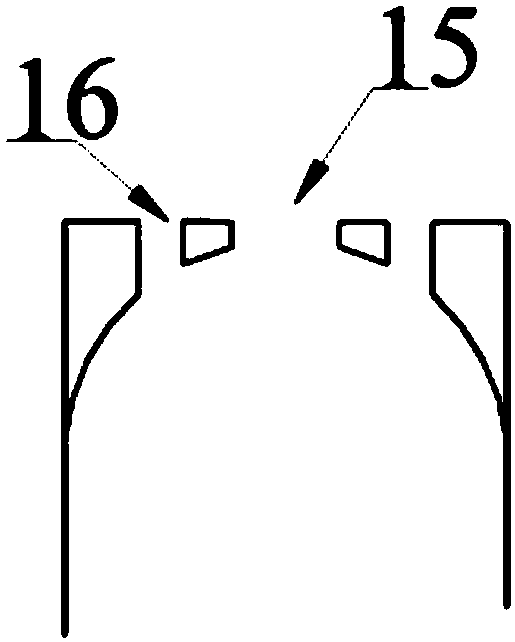

[0056] A high-sulfur coal is used as raw material, and its industrial analysis element analysis is shown in Table 1. The particle size of pulverized coal is about 0.1-0.3mm, and the flue gas is transported into the pyrolyzer from the pulverized coal inlet 4; the high-temperature sulfur-fixing agent with a particle size of 0.5-1.0mm is blown into the heat from another flue gas through the sulfur-fixing agent inlet 5 Decomposer, the flow is 1 / 10-1 / 5 of the pulverized coal flow. The flue gas enters the fluidized bed pyrolyzer through the air distribution plate 3 of the hood, and the bed temperature is controlled at 700-900°C. The pulverized coal undergoes a pyrolysis reaction, and the generated gas entrains powdered coke to contact with the sulfur-fixing agent, and about 60% of the gas mixture flows out from the airflow pipe of the inverted concave spoiler 7 . The gas mixture enters the cyclone separator 10, and the gas tar collecting device 11 after gas-solid separation. The p...

Embodiment 2

[0058] A medium-sulfur coal is used as raw material, and its industrial analysis element analysis is shown in Table 1. The particle size of pulverized coal is about 0.1-0.3mm, and the flue gas is transported into the pyrolyzer from the pulverized coal inlet 4; the high-temperature sulfur-fixing agent with a particle size of 0.5-1.0mm is blown into the heat from another flue gas through the sulfur-fixing agent inlet 5 Decomposer, the flow is 1 / 10-1 / 5 of the pulverized coal flow. The flue gas enters the fluidized bed pyrolyzer through the air distribution plate 3 of the hood, and the bed temperature is controlled at 700-900°C. The pulverized coal undergoes a pyrolysis reaction, and the generated gas entrains powdered coke to contact with the sulfur-fixing agent, and about 60% of the gas mixture flows out from the airflow pipe of the inverted concave spoiler 7 . The gas mixture enters the cyclone separator 10, and the gas tar collecting device 11 after gas-solid separation. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com