Wind power gear box main shaft repair method

A technology of wind power gearbox and repair method, which is applied in the direction of metal material coating process, coating, etc., can solve the problems of high cost, high economic cost, and the failure of wind turbines to work normally, and achieve the effect of saving materials and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment:

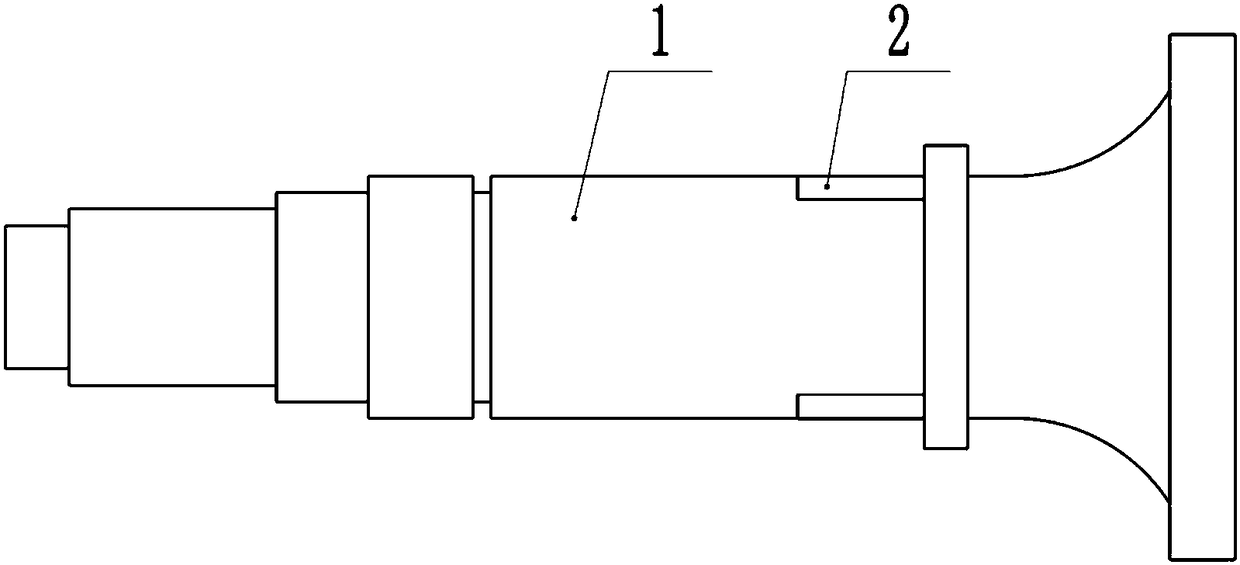

[0018] A wind power gearbox main shaft repair method for repairing such as figure 1 The spindle shown in includes the following steps:

[0019] ①Inspect the appearance of the parts, visually inspect the surface damage of the main shaft 1, whether there are scratches, wear, or even mechanical fatigue, etc., and then detect whether there are cracks and other defects on the surface of the main shaft 1;

[0020] ②Machining spindle 1 damages the surface, removes its wear or fatigue layer, and then cleans it with a cleaning agent;

[0021] ③Clamp the spindle 1 onto the machine tool and align the reference of the spindle 1, adjust the protective gas ventilation device, laser and powder feeding device, and set the laser parameters;

[0022] ④Start the machine tool to make the main shaft 1 start to rotate, and then start the protective gas ventilation device, laser and powder feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com