Oil tube head reducing joint for rod pumped well pump inspection operation

A technology of reducing joints and pumping wells, applied in drilling pipes, casings, drilling equipment, etc., can solve the problems of pollution of the natural environment, waste of resources, steam burns, etc., to avoid environmental pollution, reduce safety accidents, and avoid energy wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

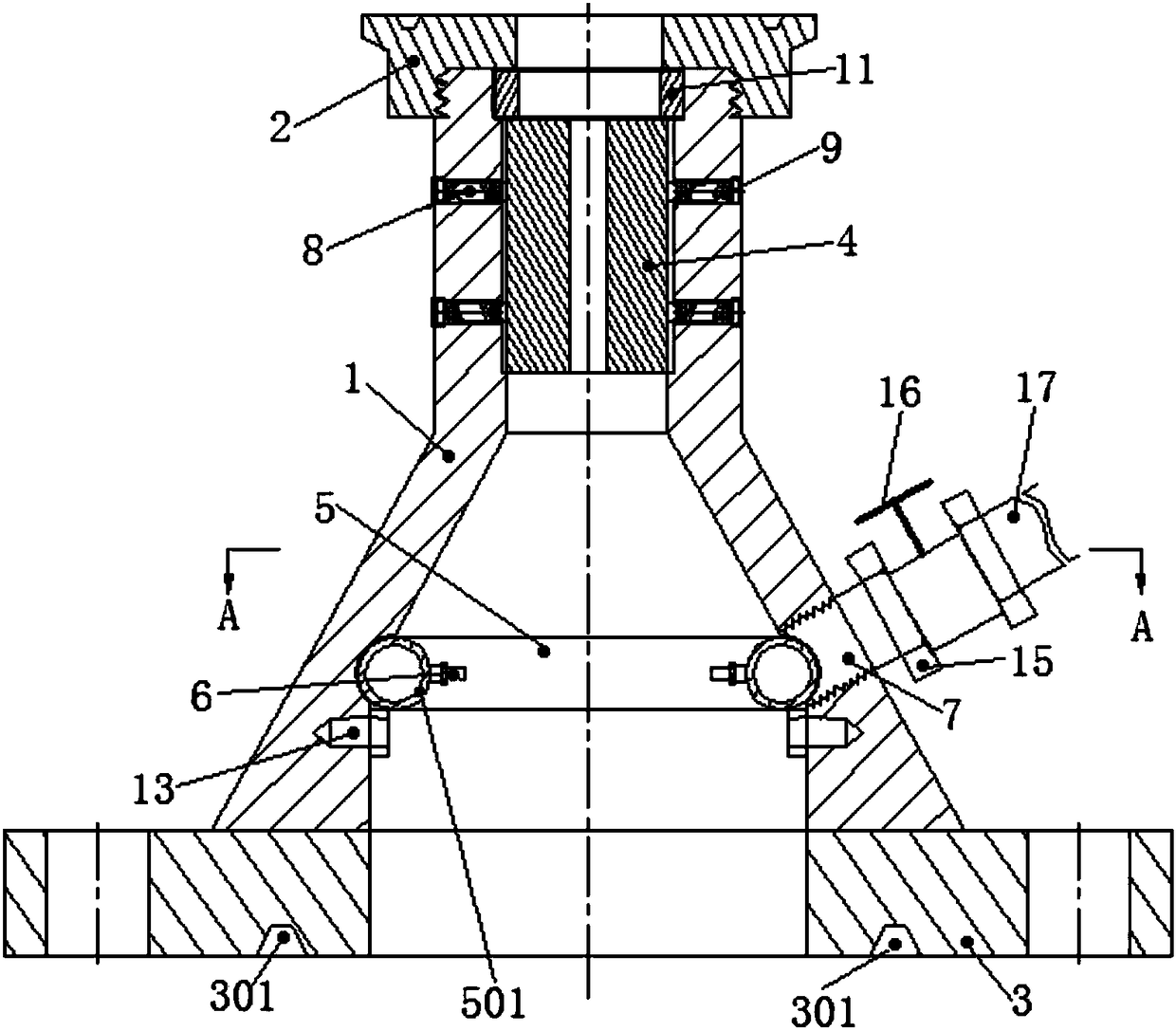

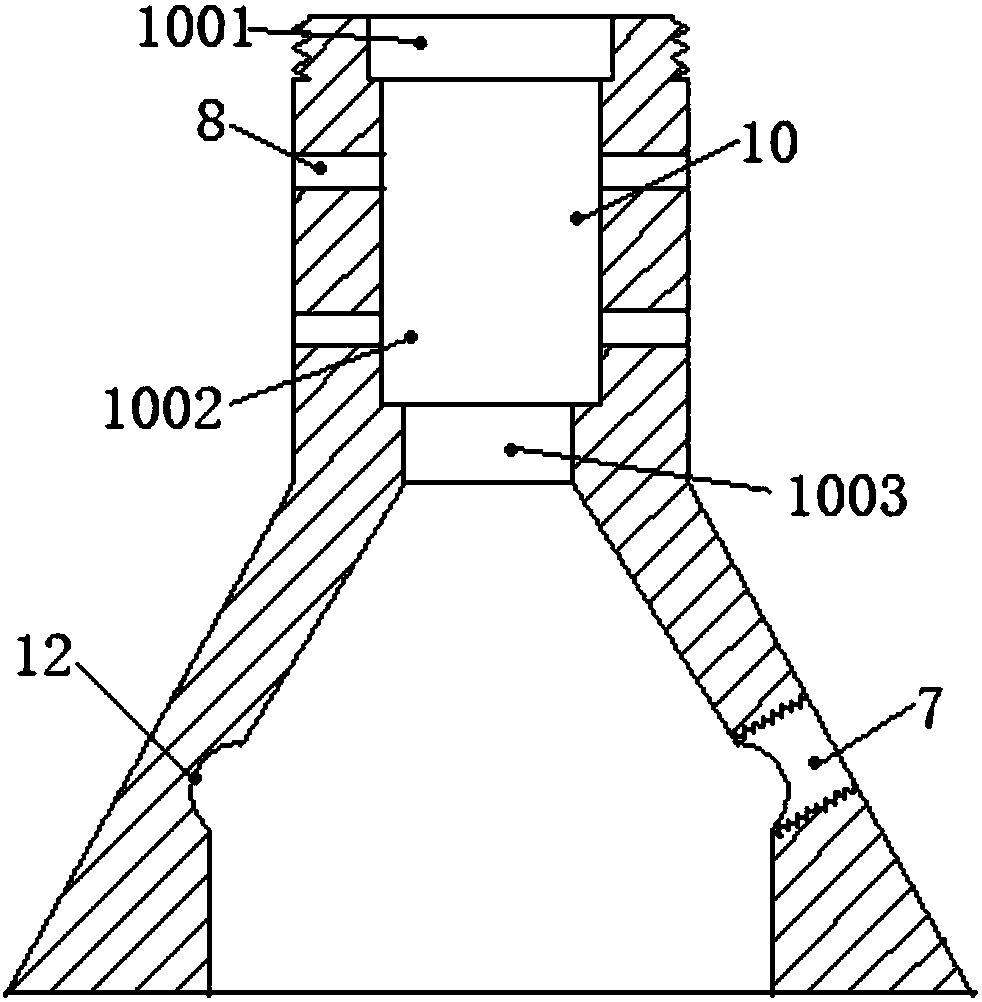

[0058] Before describing the embodiments of the present invention in further detail, it should be pointed out that the tubing head reducing joint used in the pumping unit well inspection pump operation in the embodiment of the present invention is not the tubing head reducing joint frequently used by those skilled in the art. The tubing head reducer in the middle is a connecting part between the big four-way of the Christmas tree in a pumping well and the total production valve. It is made of cast steel and is generally based on the pressure of the Christmas tree (25~70MPa) and use (water injection well). , Oil production wells), functional requirements (land use, offshore use) and other conditions, the diameter is generally changed from 180-350mm to 65mm, and its height is generally 150-200mm, which can only be used to switch the connection mode and hang and seal effect.

[0059] In order to make the objectives, technical solutions and advantages of the present invention clearer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com