Four-grade purification system and method for all pollutants of coal-fired flue gas

A coal-fired flue gas and purification system technology, applied in the field of resources and environment, can solve the problems of poor dust removal effect, high removal efficiency, and difficult fine removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings; Forms commonly known to those skilled in the art.

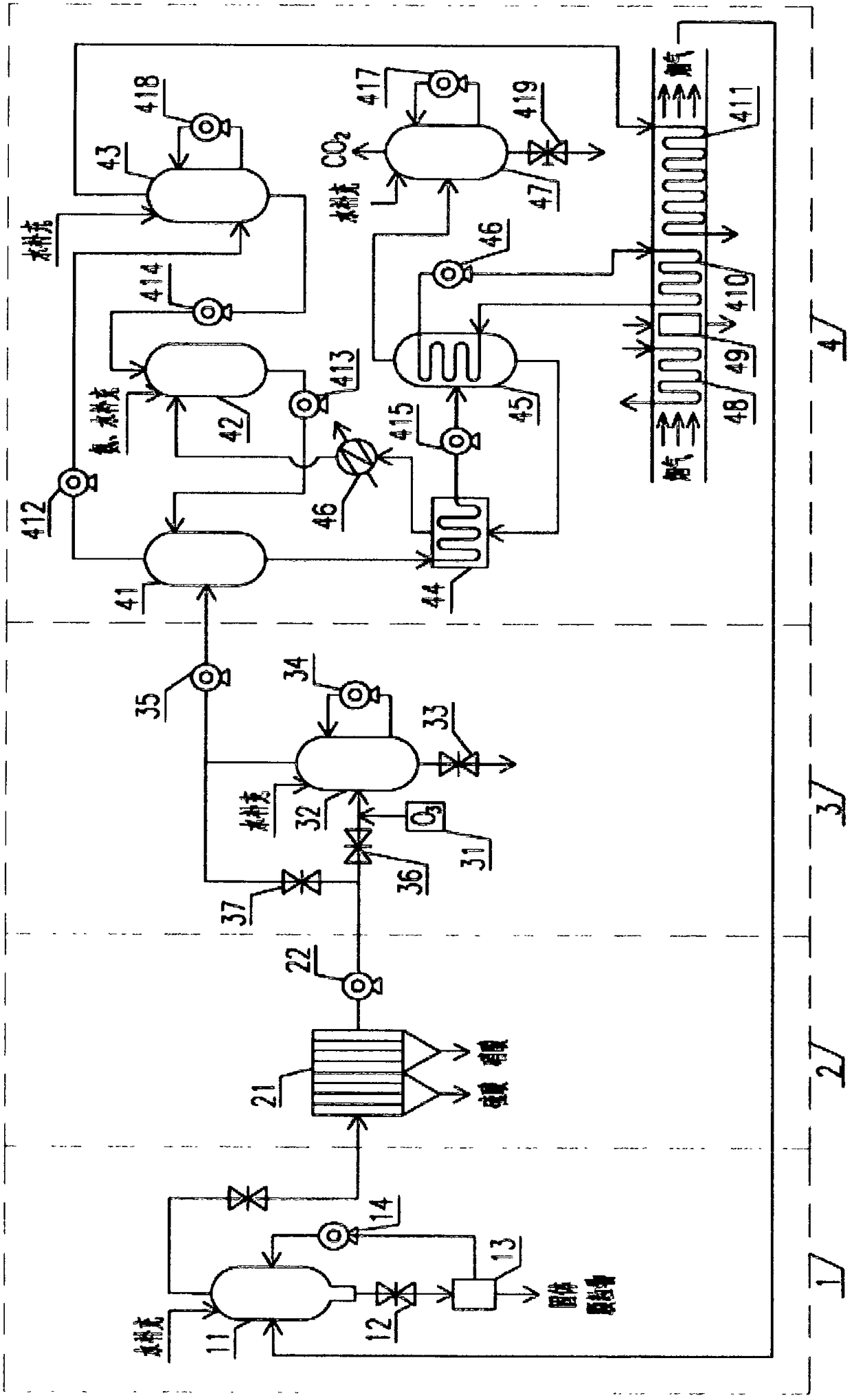

[0061] In an exemplary embodiment of the present invention, a four-stage purification system for all pollutants in coal-fired flue gas is provided. Please refer to figure 1 , the system includes: first level: tower purification system; second level: combined activated carbon fiber purification system; third level: ozone purification system; fourth level: ammonia decarbonization system.

[0062] Each component of the four-stage purification system for all pollutants in the coal-fired flue gas of this embodiment will be described in detail below.

[0063] The first stage: the tower type wet purification system includes the spray tower 11, its function is to use the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com