Double-working medium coal-fired power generation system and method

A technology of power generation system and dual working medium, applied in steam generation, steam generation device, machine/engine, etc., can solve the problems that affect the structural strength of the wall surface insulation furnace wall, the furnace wall surface cannot be effectively cooled, and the boiler exhaust gas temperature is high. , to achieve the effect of reducing the number of heating surfaces, excellent power generation cost, and high heat exchange intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

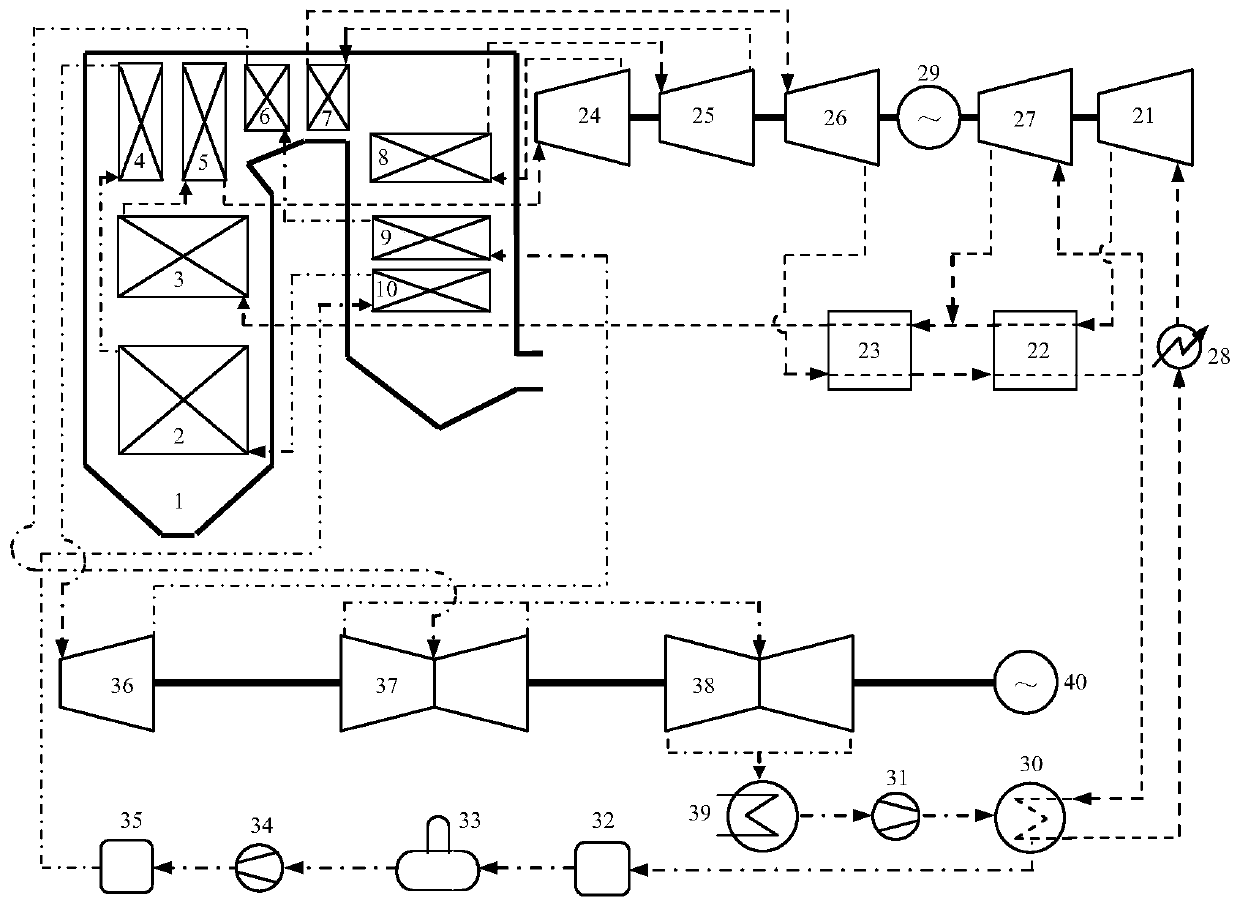

[0024] Such as figure 1 As shown, the biomass direct combustion power generation system according to the embodiment of the present invention mainly includes a boiler 1, a supercritical carbon dioxide cycle, and an ultra-supercritical steam cycle.

[0025] The boiler 1 has a furnace, a horizontal flue and a tail flue. The lower part of the furnace is equipped with a water-cooled wall 2 and an air-cooled wall 3. The upper part of the furnace is equipped with a steam superheater 4 and a carbon dioxide superheater 5. The horizontal flue is equipped with high-temperature steam Reheater 6, carbon dioxide secondary reheater 7, carbon dioxide primary reheater 8, low-temperature steam reheater 9 and economizer 10 are installed in the tail flue.

[0026] attached figure 1 The case where two boilers 1 are connected in parallel is shown. In other embodiments, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com