Wastewater treatment device

A technology for sewage treatment equipment and water storage cavity, which is applied in chemical/physical processes, dissolving, mixers, etc., can solve the problems of inconvenient disassembly and maintenance, low mixing efficiency, complex structure, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

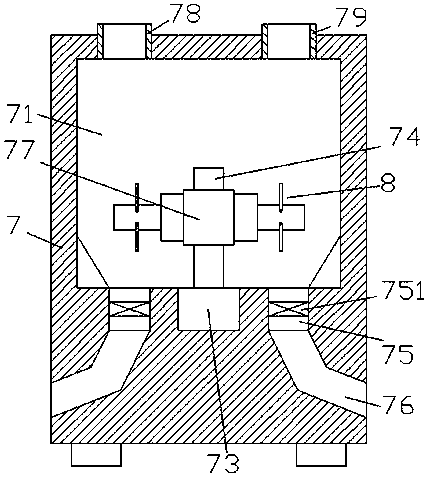

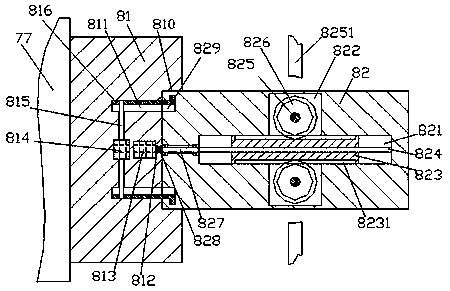

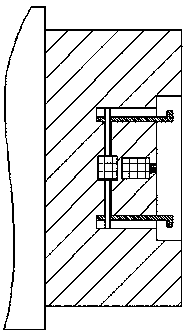

[0014] Combine below Figure 1-Figure 4 The present invention will be described in detail.

[0015] refer to Figure 1-Figure 4 , according to an embodiment of the present invention, a kind of sewage treatment equipment includes a main frame body 7, a water storage chamber 71 is arranged in the inner wall of the main frame body 7, and the top end surface of the main frame body 7 is connected with the water storage chamber The feeding chamber 78 and the dosing chamber 79 are respectively communicated between the 71, the feeding chamber 78 is used to pour sewage, the dosing chamber 79 is used to add medicine, and the bottom end surface of the water storage chamber 71 is fixed There is a first motor 73, and the top end of the first motor 73 is connected with a stirring shaft 74 pushed into the water storage chamber 71. The outer surface of the stirring shaft 74 is fixed with a fixing seat 77 in the upper direction. Stirring components 8 are arranged on the left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com