Medical garbage treatment equipment with convenient cleaning effect

A technology for processing equipment and medical waste, applied in grain processing, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of inconvenient cleaning, lack of automatic cleaning, etc., and achieve the effect of convenient operation, saving manpower, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

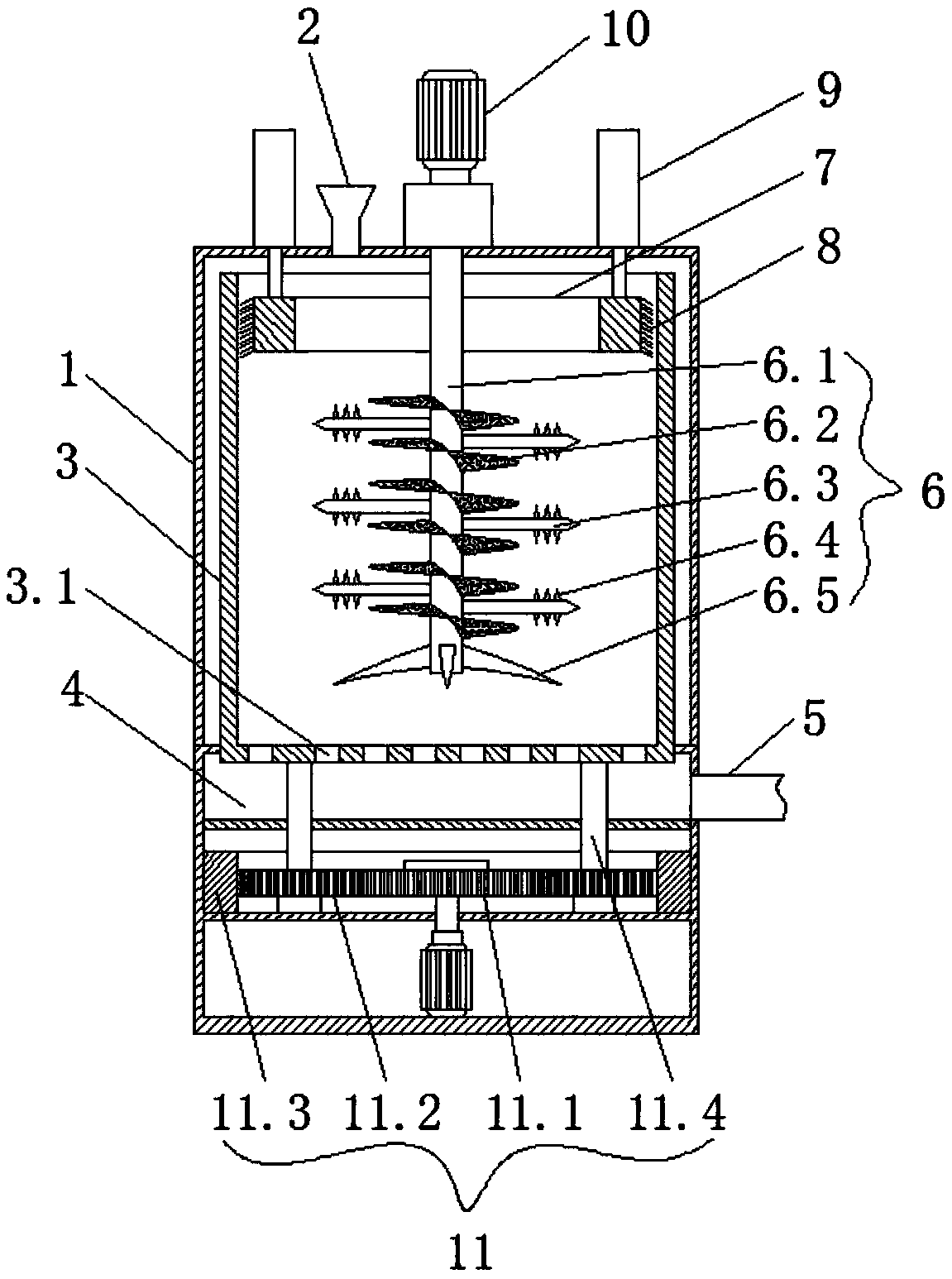

[0019] Such as Figures 1 to 2 As shown, this embodiment provides a medical waste treatment device that is easy to clean, including a housing 1, a feeding pipe 2 is arranged on the top of the housing 1, a rotating cylinder 3 with an upper end opening is arranged inside the housing 1, and the bottom of the rotating cylinder 3 is A number of through holes 3.1 are opened, and the housing 1 is provided with a waste material collection chamber 4 located below the rotating cylinder 3. Mechanism 6, the rotating cylinder 3 is provided with an annular block 7 that cooperates with the crushing mechanism 6, the crushing mechanism 6 is in the inner circle space of the annular block 7, and the outer circular surface of the annular block 7 is provided with a number of ring blocks that are in contact with the inner wall of the rotating cylinder 3 bristles 8, the top of the housing 1 is provided with two telescopic cylinders 9 arranged symmetrically with the center of the annular block 7, and...

Embodiment 2

[0022] Such as figure 1 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the crushing mechanism 6 includes a stirring shaft 6.1, and the stirring shaft 6.1 is connected to a drive motor 10 arranged on the top of the housing 1. The stirring shaft 6.1 is provided with a spiral stirring piece 6.2 and a number of crushing blades 6.3, the crushing blades 6.3 and the spiral stirring pieces 6.2 are arranged alternately, and the upper and lower surfaces of all the crushing blades 6.3 are provided with a number of evenly distributed serrations 6.4, and the stirring shaft 6.1 The bottom is provided with a number of uniformly distributed downward-curved stirring blades 6.5.

[0023] In this embodiment, the combined mechanism of the helical stirring member, the crushing blade and the sawtooth in the crushing mechanism has a good crushing effect on medical waste and high working efficiency.

Embodiment 3

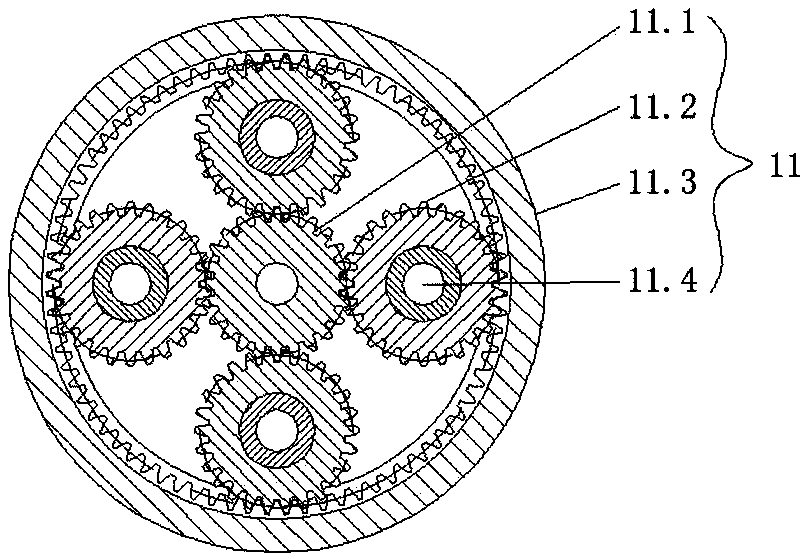

[0025] Such as Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the bottom of the rotating drum 3 is connected with a gear transmission mechanism 11 located below the waste collection chamber 4 for driving the rotating drum 3 to rotate. , the gear transmission mechanism 11 includes a center wheel 11.1, and the center wheel 11.1 is meshed with a number of planetary wheels 11.2 uniformly distributed around the center wheel 11.1. 11.2 is located on the ring gear of the inner gear cylinder 11.3, and the center of each planetary gear 11.2 is provided with a rotating shaft 11.4, and each rotating shaft 11.4 is movably connected with the bottom of the rotating cylinder 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com