Rotary powder coating iron remover

A powder coating and rotary technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of uneven feeding, reduce the adsorption capacity of the magnetic frame, and affect the quality of powder coatings, so as to facilitate adsorption and expand area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

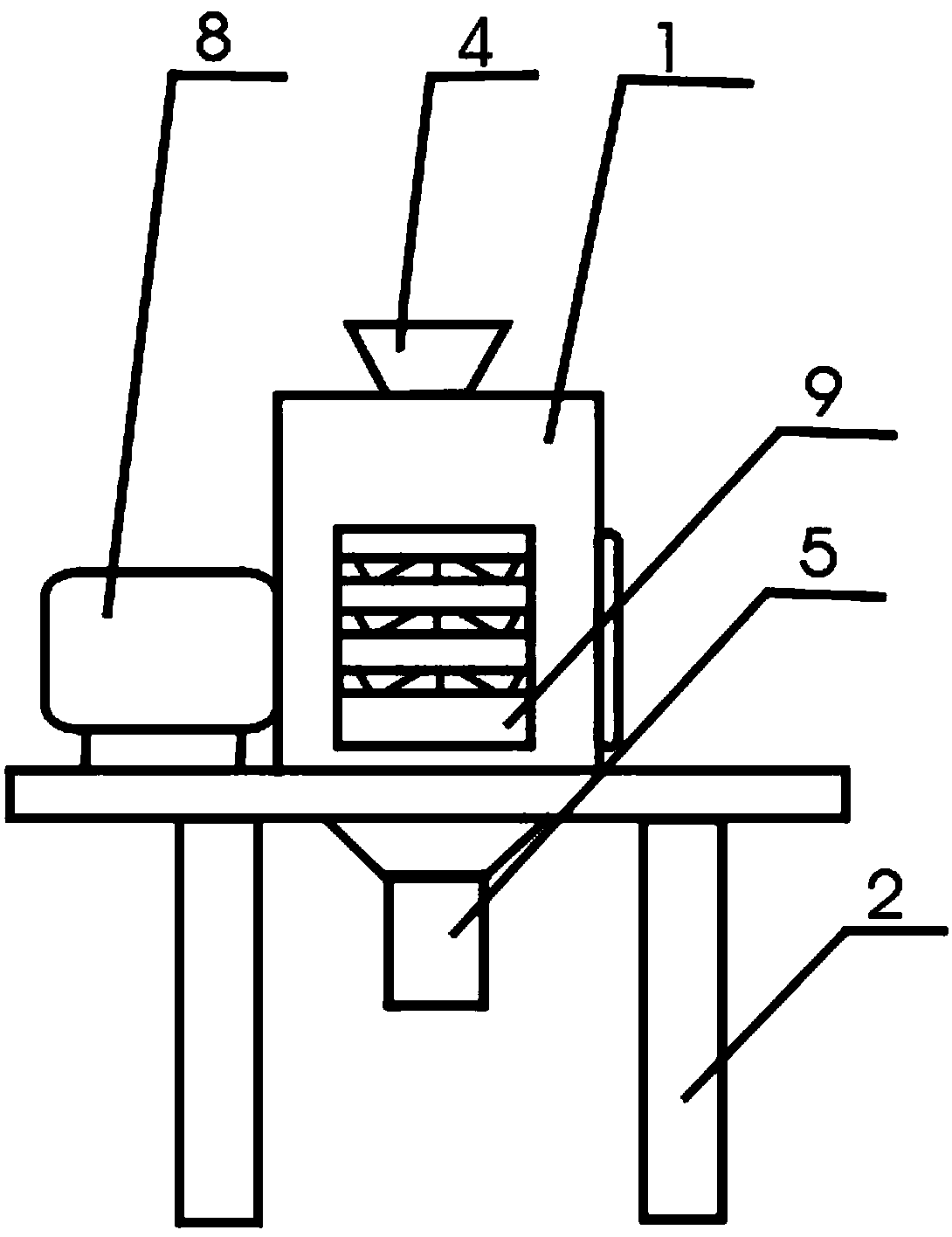

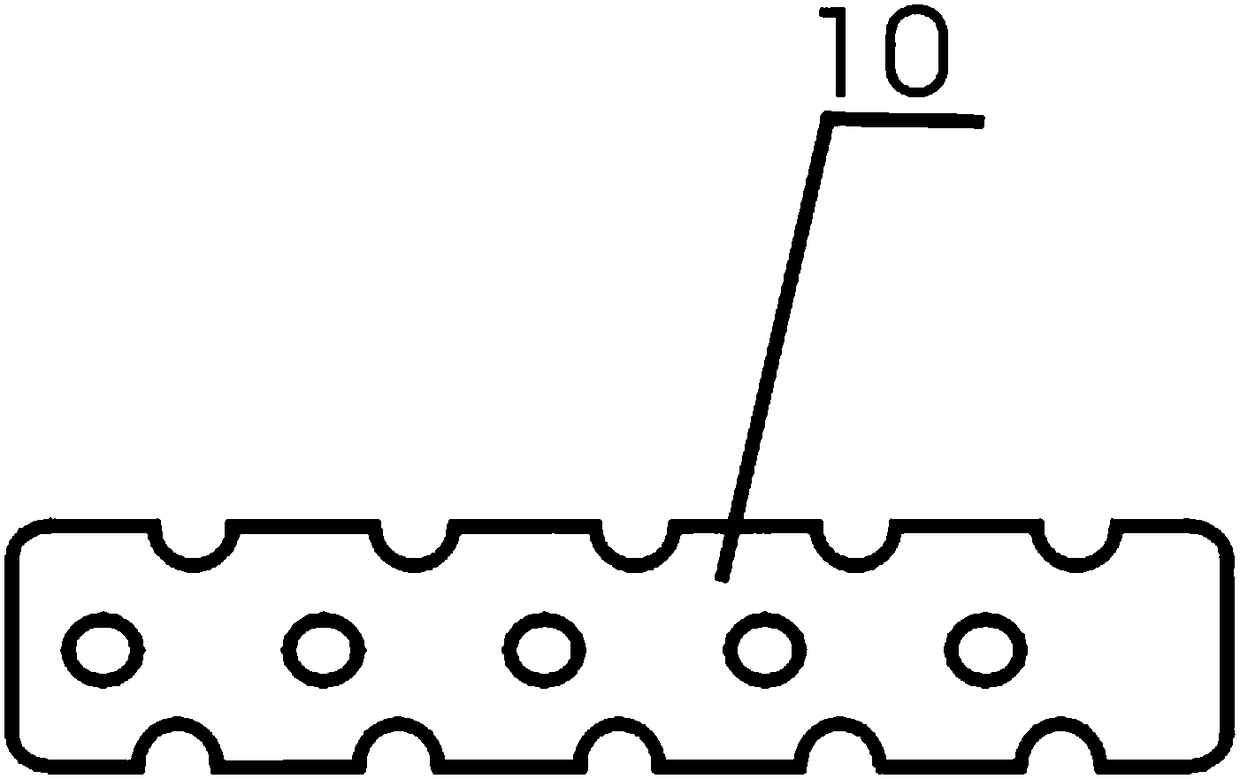

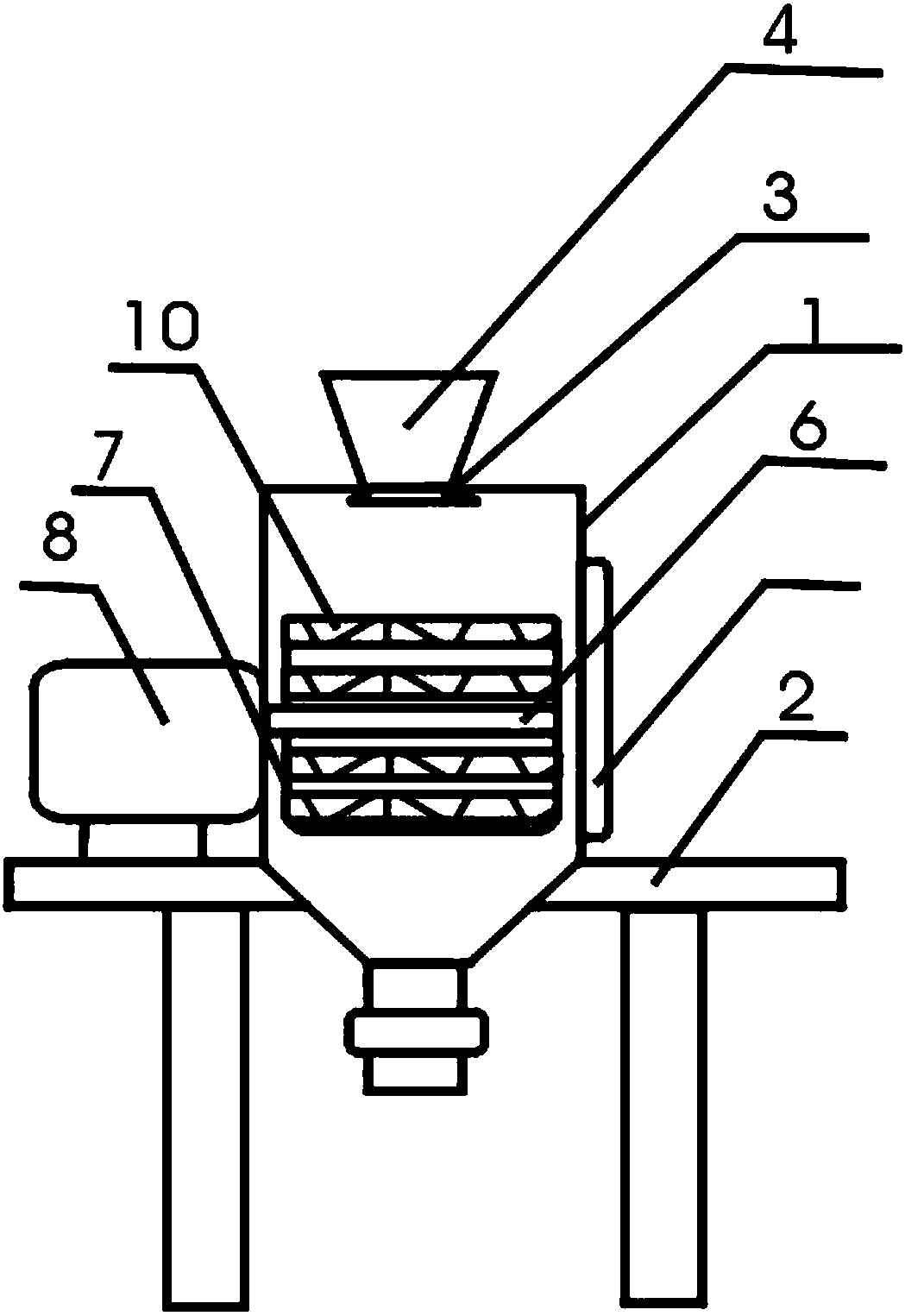

[0012] The invention is a rotary powder coating iron removal device, which includes a casing 1, a bracket 2, a diverter plate 3, a feed port 4, a discharge port 5, a rotating shaft 6, a magnetic frame 7, a motor 8, an observation window 9, and a casing 1 There is a feed port 4 on the upper side, a splitter plate 3 is installed inside the feed port 4, a discharge port 5 is provided on the lower side of the housing 1, a housing 1 and a motor 8 are installed on the upper side of the bracket 2, and the motor 8 is installed outside the housing 1 A rotating shaft 6 is installed inside the housing 1, the rotating shaft 6 is connected to the motor 8, the rotating shaft 6 is connected to the magnetic frame 7, an observation window 9 is provided on the outer side of the housing 1, and a magnetic rod 10 is provided on the magnetic frame 7, and the magnetic rod 10 is a concave-convex structure.

Embodiment 2

[0014] When in use, the present invention is opened, and the motor 8 drives the rotating shaft 6 to rotate, and then the rotating shaft 6 drives the magnetic frame 7 to rotate, and then the staff puts the powder coating into the casing 1 of the present invention through the feed port 4, and the feed port 4 is equipped with Splitter plate 3, splitter plate 3 can divert the incoming powder, so that the powder can pass through the magnetic frame 7 for impurity adsorption. When the magnetic frame 7 rotates, the iron filings are adsorbed in the concave-convex structure of the magnetic rod 10, which facilitates the adsorption of iron filings. When the magnetic frame 7 is adsorbed, the staff can observe the magnetic frame 7 in the shell 1 through the observation window 9. When it is found that the magnetic frame 7 absorbs too much iron filings, the magnetic frame 7 can be replaced or cleaned in time, which is convenient for the iron removal device in the later stage. run.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com