Improved intelligent garbage treatment equipment

A garbage disposal equipment and intelligent technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large occupied area, small effect surface, inconvenient disposal, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

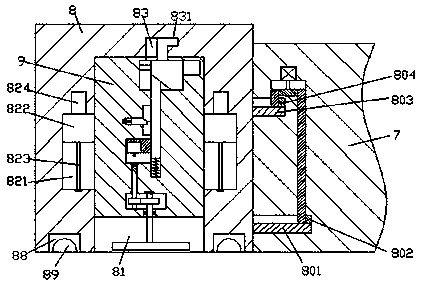

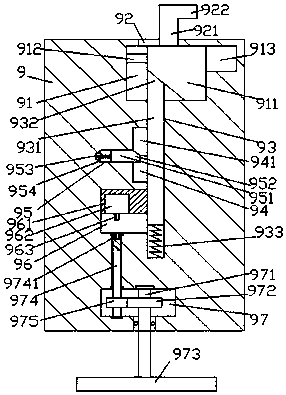

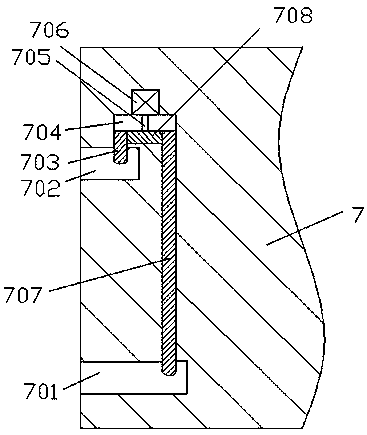

[0016] Such as figure 1 , figure 2 with image 3As shown, an improved intelligent garbage disposal device of the present invention includes a walking body 7, a fixing frame 8 installed on the front side of the walking body 7, and the upper and lower positions of the front end of the walking body 7 are provided with The opening of the first mounting groove 701 and the second mounting groove 702 forward, the upper inner walls of the first mounting groove 701 and the second mounting groove 702 respectively have a first locking arm 707 and a first locking arm 707 which can move up and down. The second lock arm 703, the walking body 7 between the first lock arm 707 and the second lock arm 703 is provided with a connecting groove 704, and the connecting groove 704 is slidably fitted with the The connecting arm 708 fixedly connected to the first locking arm 707 and the second locking arm 703, the connecting arm 708 is screwed and fitted with a vertically arranged threaded post 705...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com