Method for mixing raw material and solvent in lubricant extraction process

A technology for lubricating oil and solvent is applied in the field of mixing raw material and solvent in lubricating oil extraction process, which can solve the problems of incomplete extraction, low yield of refined oil in the device, poor mixing effect of raw material and furfural solvent, etc., and achieves improved yield , the effect of enhancing liquidity and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

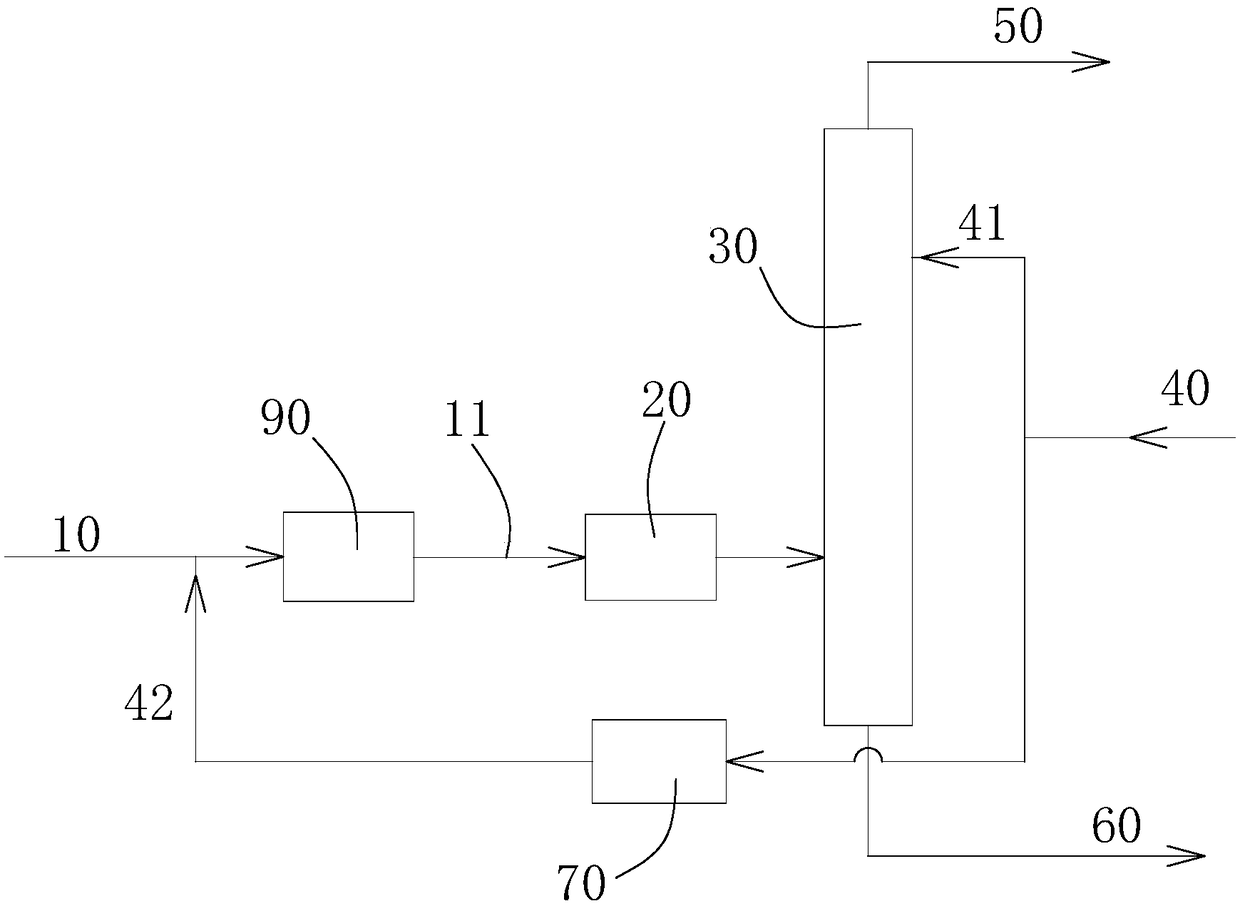

[0024] see figure 1 , a method for mixing raw materials and solvents in a lubricating oil extraction process, comprising the following processes:

[0025] (1) Furfural solvent 40 is divided into two parts, furfural solvent A42 and furfural solvent B41, wherein furfural solvent A42 is squeezed in the mixer 90 with pump 70, and simultaneously, raw material 10 enters in the mixer 90, after passing through the mixer 90 , the furfural solvent A42 and the raw material 10 form a premix 11, the premix 11 enters the raw material cooler 20 for cooling, and the cooled premix 11 enters the lower part of the extraction tower 30. The temperature of the premix 11 coming out of the raw material cooler 20 was 85°C. In premix 11, the mass ratio of furfural solvent A42 to raw material 10 is 15:100.

[0026] (2) In the extraction tower 30, the furfural solvent B41 enters from the upper part of the extraction tower 30, and the raw materials in the premix are upwardly contacted with the furfural...

Embodiment 2

[0031] A method for mixing raw materials and solvents in a lubricating oil extraction process, comprising the following processes:

[0032] (1) The furfural solvent is divided into two parts: furfural solvent A and furfural solvent B, wherein furfural solvent A and raw materials are mixed together by a mixer to form a premix, and the premix enters the lower part of the extraction tower after passing through the raw material cooler ; The temperature of the premix coming out of the raw material cooler is 100°C. In the premix, the mass ratio of furfural solvent A to raw materials is 20:100.

[0033] (2) In the extraction tower, the furfural solvent B enters from the upper part of the extraction tower, and the raw materials in the premix are in reverse contact with the furfural solvent B upwards. The temperature of the furfural solvent B entering from the upper part of the extraction tower is 135°C.

[0034] (3) Refined liquid is formed at the top of the extraction tower, and th...

Embodiment 3

[0038] A method for mixing raw materials and solvents in a lubricating oil extraction process, comprising the following processes:

[0039] (1) The furfural solvent is divided into two parts: furfural solvent A and furfural solvent B, wherein furfural solvent A and raw materials are mixed together by a mixer to form a premix, and the premix enters the lower part of the extraction tower after passing through the raw material cooler ; The temperature of the premix coming out of the raw material cooler is 95°C. In the premix, the mass ratio of furfural solvent to raw material is 18:100.

[0040] (2) In the extraction tower, the furfural solvent B enters from the upper part of the extraction tower, and the raw materials in the premix are in reverse contact with the furfural solvent B upwards. The temperature of the furfural solvent B entering from the upper part of the extraction tower is 130°C.

[0041] (3) Refined liquid is formed at the top of the extraction tower, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com