Soft-belt-free four-point-contact ball slewing support bearing

A slewing ring bearing and four-point contact technology, which is applied to rolling contact bearings, ball bearings, and rotating bearings, etc., can solve the problems of reducing the service life of slewing rings, low work efficiency, and increasing maintenance costs for enterprises, and achieves improvement. The effect of working efficiency, simple operation process and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

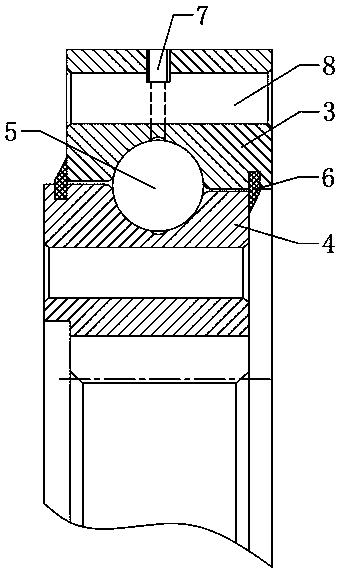

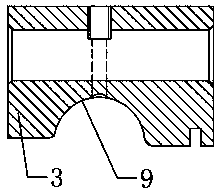

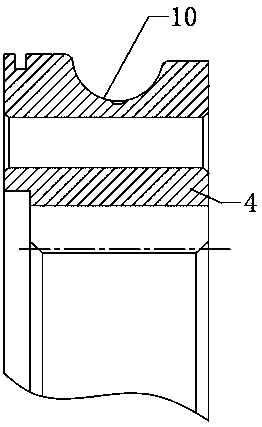

[0037] like Figure 1-3 As shown, a four-point contact ball slewing ring bearing without a soft belt includes an outer ring 3 without a soft belt, an inner gear ring 4 without a soft belt, and is placed between the outer ring 3 without a soft belt and the inner gear ring 4 without a soft belt The rolling element 5, the non-soft belt outer ring 3 and the non-soft belt internal gear 4 are all made of 40GrMo, and the inner diameter of the circumference of the non-soft belt outer ring 3 is provided with a non-soft belt annular groove-9, and the non-soft belt inner gear The outer diameter of the circumference of the ring 4 is provided with an annular groove without a soft band two 10, and the annular groove without a soft band one 9 is combined with the annular groove two 10 without a soft band to form a cavity with a circular cross section, and the cavity is placed with The steel ball is provided with a sealing ring 6 for dustproof effect at the junction of the non-soft belt outer...

Embodiment 2

[0044] like Figure 1-3 As shown, a four-point contact ball slewing ring bearing without a soft belt includes an outer ring 3 without a soft belt, an inner gear ring 4 without a soft belt, and is placed between the outer ring 3 without a soft belt and the inner gear ring 4 without a soft belt The rolling element 5, the non-soft belt outer ring 3 and the non-soft belt internal gear 4 are all made of 40GrMo, and the inner diameter of the circumference of the non-soft belt outer ring 3 is provided with a non-soft belt annular groove-9, and the non-soft belt inner gear The outer diameter of the circumference of the ring 4 is provided with an annular groove without a soft band two 10, and the annular groove without a soft band one 9 is combined with the annular groove two 10 without a soft band to form a cavity with a circular cross section, and the cavity is placed with The steel ball is provided with a sealing ring 6 for dustproof effect at the junction of the non-soft belt outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com