Quenching method of soft band free slewing bearing sleeve ring

A technology of slewing bearings and ferrules, which is applied in the field of heat treatment of slewing bearings, can solve the problems of increasing equipment maintenance costs, reducing the service life of slewing bearings, and limiting the use range of slewing bearings, so as to simplify the steps of heat treatment, ensure accuracy, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

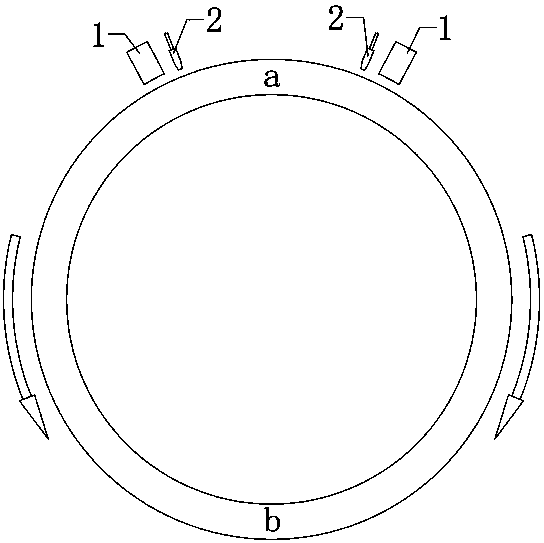

[0029] As shown in the figure, a quenching method for a slewing bearing ring without a soft belt includes the following steps:

[0030] Step 1. Positioning of the workpiece: install the workpiece horizontally on the working platform of the machine tool and fix it;

[0031] Step 2. Determine the center position of the workpiece: a distance measuring sensor is installed on the spindle of the machine tool. The distance measuring sensor is an ultrasonic distance measuring sensor. Center coordinates, record and store the coordinate values in the PLC programming control system of the machine tool, and determine the starting point a position, end point b position and the motion radius of the induction heater according to the coordinate values;

[0032]Step 3. Heating and cooling of the workpiece: At the initial position, the two induction heaters installed on the mobile device of the machine tool are located at the initial zero point a at the same time, and the distance between the...

Embodiment 2

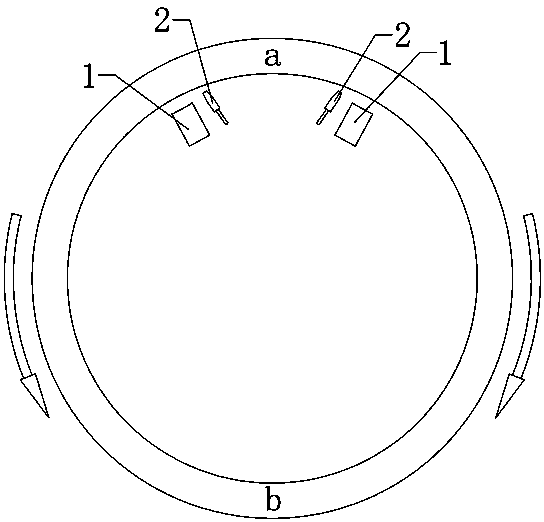

[0035] As shown in the figure, a quenching method for a slewing bearing ring without a soft belt includes the following steps:

[0036] Step 1. Positioning of the workpiece: install the workpiece horizontally on the working platform of the machine tool and fix it;

[0037] Step 2. Determine the center position of the workpiece: a distance measuring sensor is installed on the spindle of the machine tool. The distance measuring sensor is an infrared distance measuring sensor. Center coordinates, record and store the coordinate values in the PLC programming control system of the machine tool, and determine the starting point a position, end point b position and the motion radius of the induction heater according to the coordinate values;

[0038] Step 3. Heating and cooling of the workpiece: At the initial position, the two induction heaters installed on the mobile device of the machine tool are located at the initial zero point a at the same time, and the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com