Non-soft-belt large-taper-angle double-row tapered roller slewing bearing

A technology of slewing bearing and tapered roller, applied in the direction of roller bearing, rolling contact bearing, bearing of rotary motion, etc., to achieve the effect of simple operation process, improve work efficiency, and simplify the steps of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

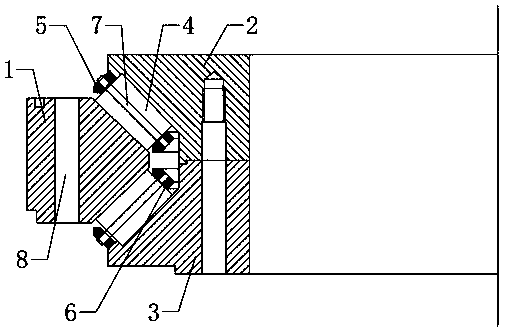

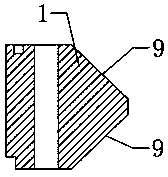

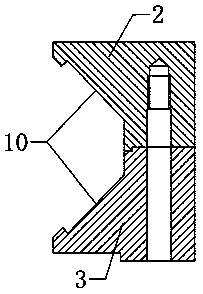

[0037] Such as Figure 1-3 As shown, a double-row tapered roller slewing bearing with no soft belt and large cone angle includes a soft belt outer ring 1, a soft belt first inner ring 2 and a soft belt second inner ring 3 of equal size. The outer ring 1 without soft belt, the first inner ring 2 without soft belt and the second inner ring 3 without soft belt are all made of 42GrMo, the first inner ring 2 without soft belt and the second inner ring 3 without soft belt are symmetrically arranged and passed through bolts Connecting, the first inner ring 2 without soft belt and the second inner ring 3 without soft belt are combined to form an inner ring structure, the thickness of the inner ring structure is greater than the thickness of the outer ring 1 without soft belt, and the circumferential direction of the outer ring 1 without soft belt There are two symmetrical and inclined first rolling working surfaces 9 without soft belts on the inner side, and a second rolling working s...

Embodiment 2

[0044] Such as Figure 1-3 As shown, a double-row tapered roller slewing bearing with no soft belt and large cone angle includes a soft belt outer ring 1, a soft belt first inner ring 2 and a soft belt second inner ring 3 of equal size. The outer ring 1 without soft belt, the first inner ring 2 without soft belt and the second inner ring 3 without soft belt are all made of 42GrMo, the first inner ring 2 without soft belt and the second inner ring 3 without soft belt are symmetrically arranged and passed through bolts Connecting, the first inner ring 2 without soft belt and the second inner ring 3 without soft belt are combined to form an inner ring structure, the thickness of the inner ring structure is greater than the thickness of the outer ring 1 without soft belt, and the circumferential direction of the outer ring 1 without soft belt There are two symmetrical and inclined first rolling working surfaces 9 without soft belts on the inner side, and a second rolling working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com