Method for improving rinsing quality of strip steel in pickling and rolling unit

A strip and unit technology, applied in the field of improving the strip rinsing quality of pickling mills, can solve the problems that the strip rinsing quality is difficult to meet the standard requirements, the surface is prone to oxidation reaction, the surface reflectivity is insufficient, etc., and the strip rinsing can be improved. quality, improving the quality of cold-rolled products, reducing the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

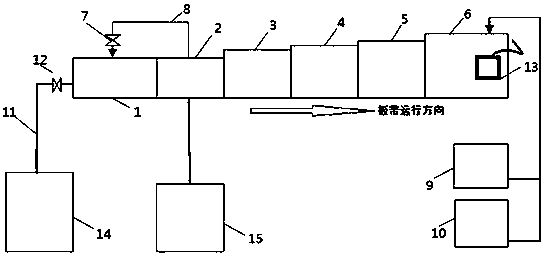

[0015] Embodiment 1: first the condensed water in the condensed water tank 9 is pumped into the 5# rinse tank 6, and observe the numerical value of the conductivity detector 13 in the 5# rinse tank 6, and find that the conductivity detector 13 in the 5# rinse tank 6 The detected conductivity is 35μs / cm, and the conductivity detector 13 sends a control command to the condensed water tank 9 to control the condensed water supply at 12-15m³ / h; The spray valve 7 no longer draws condensed water into the pre-rinse tank 1 through the spray water pipe 8; at this time, the pH value of the rinse water in the rinse tank 2 of 1# is 1.5, and the pH value of the rinse water in the rinse tank 3 of 2# The value is 3.0, the pH value of the rinse water in the 3# rinse tank 4 is 4.0, the pH value of the rinse water in the 4# rinse tank 5 is 5.5, and the pH value in the 5# rinse tank 6 is 7; The strip after pickling in tank 14 is rinsed sequentially through pre-rinsing tank 1, 1# rinsing tank 2, 2...

Embodiment 2

[0016] Embodiment 2: first the condensed water in the condensed water tank 9 is pumped into the 5# rinsing tank 6, and observe the numerical value of the conductivity detector 13 in the 5# rinsing tank 6, and find that the conductivity detector 13 in the 5# rinsing tank 6 The detected conductivity is 25μs / cm, and the conductivity detector 13 sends a control command to the condensed water tank 9 to control the condensed water supply at 8-10m³ / h; The spray valve 7 no longer draws the condensed water into the pre-rinse tank 1 through the spray water pipe 8; at this time, the pH value of the rinse water in the 1# rinse tank 2 is 2.0, and the pH value of the rinse water in the 2# rinse tank 3 The value is 3.5, the pH value of the rinse water in the 3# rinse tank 4 is 4.8, the pH value of the rinse water in the 4# rinse tank 5 is 6.2, and the pH value in the 5# rinse tank 6 is 7; The strip after pickling in tank 14 is rinsed through pre-rinsing tank 1, 1# rinsing tank 2, 2# rinsing ...

Embodiment 3

[0017] Embodiment 3: first the condensed water in the condensed water tank 9 is pumped into the 5# rinse tank 6, and observe the numerical value of the conductivity detector 13 in the 5# rinse tank 6, and find that the conductivity detector 13 in the 5# rinse tank 6 The detected conductivity is 13μs / cm, and the conductivity detector 13 sends a control command to the condensed water tank 9 to control the condensed water supply at 6-6.5m³ / h; Close the spray valve 7, and no longer pump the condensed water into the pre-rinse tank 1 through the spray water pipe 8; The pH value of the rinsing water in 3.8, 3# rinsing tank 4 is 4.7, the pH value of rinsing water in 4# rinsing tank 5 is 6.0, and the pH value in 5# rinsing tank 6 is 7; The plates and strips after pickling in wash tank 14 are rinsed sequentially through pre-rinse tank 1, 1# rinse tank 2, 2# rinse tank 3, 3# rinse tank 4, 4# rinse tank 5 and 5# rinse tank 6, after rinsing It was found that the surface reflectivity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com