Assembly method for phosphorous pig iron casting cathode for aluminum electrolysis

A technology of phosphorus pig iron casting and assembly method, which is applied in the field of improvement of phosphorus pig iron casting cathode assembly method for aluminum electrolysis, and achieves the effects of saving time, significant economic benefits, and improving assembly efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

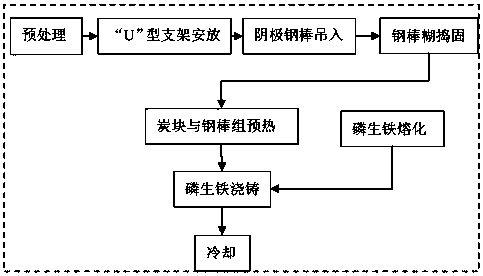

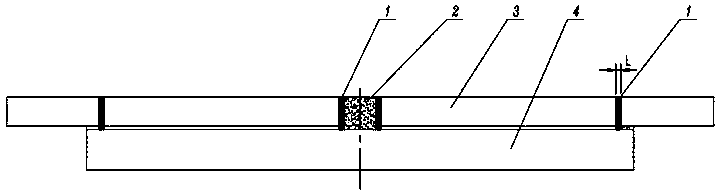

[0023] The assembly of the cathode carbon block group with double steel rods combined with the accompanying drawings figure 1 and figure 2 Description: According to the size of the dovetail groove of the cathode carbon block and the steel rod, the specific size of the "U"-shaped bracket is made: its width can not be changed due to the size of the steel rod and the dovetail groove of the cathode carbon block, take 20mm, the side wall thickness d0, and the distance between the side walls d. The size of the bottom thickness h0 and height h depends on the size of the dovetail groove of the assembled cathode carbon block and the size of the cathode steel rod. For example, the size of the end of the steel rod is 180*100mm 2 , the corresponding carbon block dovetail groove size is 195*110 (the narrowest point) mm 2 , then d0 is 4mm, d is 100mm, h0 is 15mm, and h is 180mm. according to figure 1 Process flow for assembly and casting: Pretreatment of steel rods and carbon block dove...

Embodiment example 2

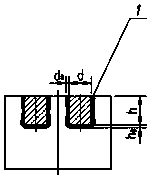

[0025] The cathode carbon block assembly of a single steel rod is assembled as image 3 , the size of the "U"-shaped bracket: its width can not be changed due to the size of the steel rod and the dovetail slot of the cathode carbon block, take 20mm, and the dimensions of the side wall thickness d0, side wall spacing d, bottom thickness h0 and height h are based on the size of the cathode carbon The size of the end of the block dovetail groove and the size of the cathode steel rod are determined: for example, the size of the end of the steel rod is 280*200mm 2 , the corresponding carbon block dovetail groove size is 310*220mm 2 , then d0 is 8mm, d is 200mm, h0 is 30mm, and h is 280mm. according to figure 1 Process flow, pretreatment of steel rods and carbon block dovetail grooves - cleaning the oxide layer on the surface of steel rods, blowing out the dust inside the cathode carbon block dovetail grooves with compressed air; placing a special "U"-shaped bracket on the dovetai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com