Structure of combined cathode steel bar and cathode carbon block set

A technology of cathode carbon block and cathode steel rod, which is applied in the field of electrolytic cells, can solve the problems of complex structure of the cathode end, lack of large-scale industrial application, and large horizontal heat dissipation of the cathode end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

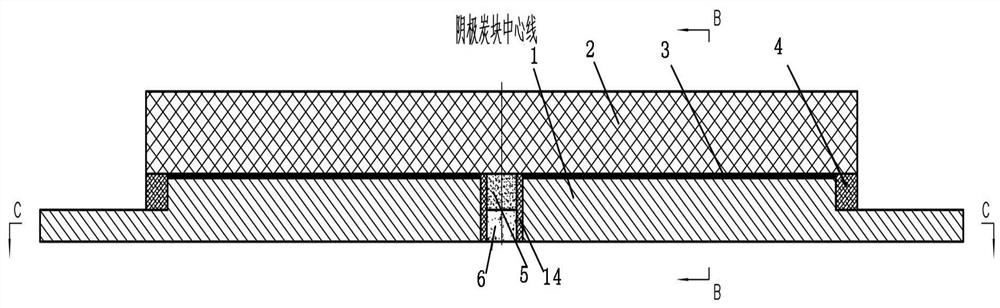

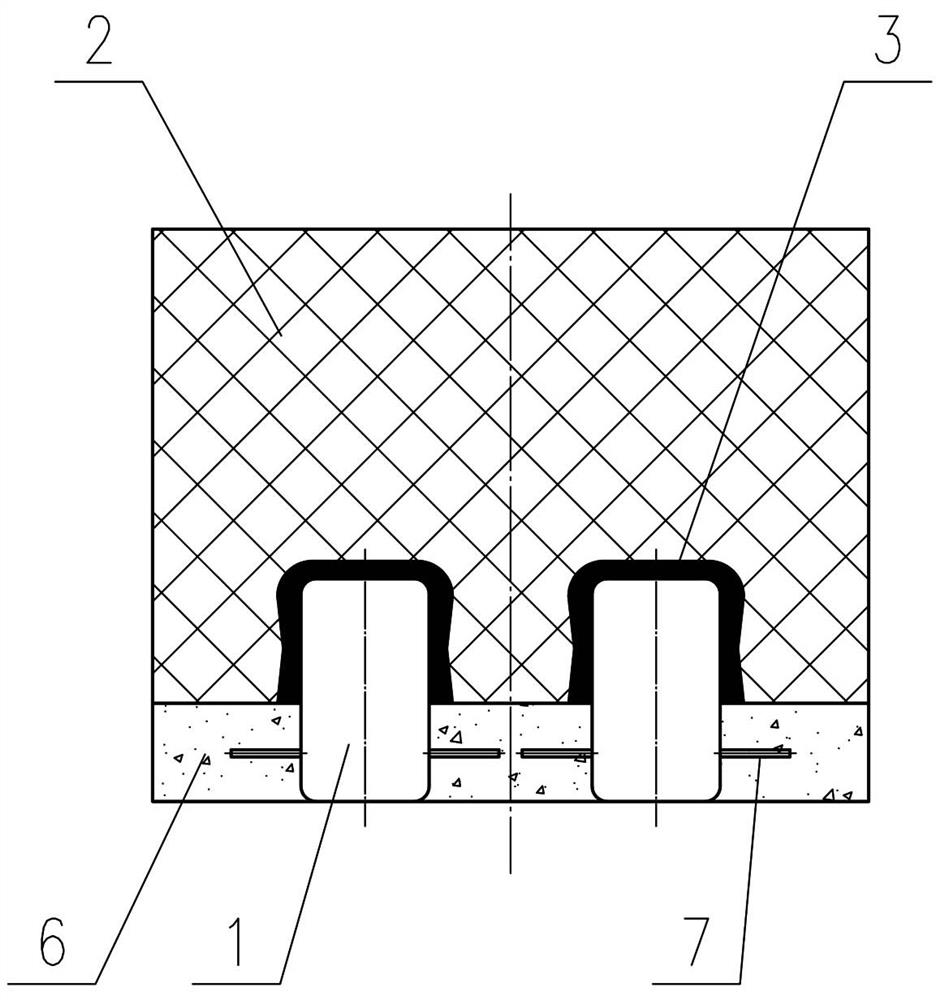

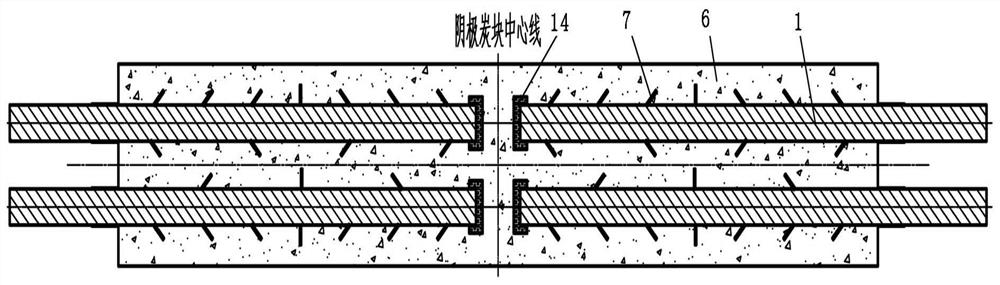

[0043] Such as Figure 1-3 As shown, a composite cathode steel rod and cathode carbon block group structure, the cathode steel rod 1 is fixed at the lower part of the cathode carbon block 2 through a solid carbon paste or phosphorus pig iron 3, and the cathode steel rod 1 is exposed at the lower part of the cathode carbon block 2 Casting with refractory and anti-seepage castable 6, the cross section of cathode steel rod 1 near the end of cathode carbon block 2 in the cathode block steel rod groove becomes smaller, and the end part is filled with high temperature resistant and compressible in the space formed in this area Material 4, to absorb the thermal expansion of the cathode steel rod. A central high temperature resistant compressible material 14 is provided outside the end of the cathode steel rod 1 below the middle of the cathode carbon block 2 to absorb the thermal expansion of the cathode steel rod. There are four cathode steel rods 1, which are arranged symmetrically...

Embodiment 2

[0049] Such as Figure 4As shown, a composite cathode steel rod and cathode carbon block group structure, the cathode steel rod 1 is fastened and fixed by carbon paste at the lower part of the cathode carbon block 2, and the exposed part of the cathode steel rod 1 is fire-resistant and seepage-proof at the lower part of the cathode carbon block 2 The pouring material 6 is poured, and the section of the cathode steel rod 1 close to the end of the cathode block 2 in the cathode block becomes smaller, and the space formed in this area is filled with a high-temperature-resistant compressible material 4 at the end to absorb the cathode Thermal expansion of the steel rod. A central high temperature resistant compressible material 14 is provided outside the end of the cathode steel rod 1 below the middle of the cathode carbon block 2 to absorb the thermal expansion of the cathode steel rod. There are four cathode steel rods 1, which are arranged symmetrically with the center line of...

Embodiment 3

[0054] Such as Figure 5 As shown, both sides of the protruding end of the cathode steel rod 1 in embodiment 1 increase its cross-sectional area by welding to reduce the resistance of this part of the cathode steel rod 1, and the others are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com