Aluminum electrolysis cathode steel rod, preparation method and aluminum electrolysis cell

A cathode steel rod and aluminum electrolysis technology, applied in the field of aluminum electrolysis equipment, can solve problems such as excessively high cathode voltage drop and horizontal current, and achieve the effects of reducing energy consumption, reducing horizontal current, and reducing the generation of horizontal current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A novel cathode steel rod for aluminum electrolysis and a preparation method thereof, wherein the cathode steel rod is a non-through-length steel-copper alloy rod. First divide the steel-copper alloy rod rough billet with a copper content of 6wt% into two equal parts, left and right, and carry out regional melting, starting from the left end of the steel-copper alloy billet to the right end for regional melting, and controlling the melting speed For 12cm / h, carry out 2 zone melting. During the first zone smelting, the melting temperature in the melting zone was controlled at 1484°C, and the copper content in the obtained right section was 8.1wt% when smelting from the left section to the right section; during the second zone smelting, the melting zone temperature was controlled at 1439°C, Regional smelting is carried out on the left section, the copper content in the obtained left section is 4.05%, and the finished aluminum electrolysis cathode steel rod is obtained. T...

Embodiment 2

[0066] A novel cathode steel rod for aluminum electrolysis and a preparation method thereof, wherein the cathode steel rod is a non-through-length steel-copper alloy rod. First, the steel-copper alloy rod rough billet with a copper content of 6wt% is unevenly divided into left and right two sections, and regional melting is carried out from the left end of the steel-copper alloy rod rough billet to the right end, and the melting speed is controlled at 12cm / h, perform 2 zone smelting. During the first zone smelting, the melting temperature in the melting zone was controlled at 1484°C, and the copper content in the obtained right section was 8.1wt% when smelting from the left section to the right section; during the second zone smelting, the melting zone temperature was controlled at 1439°C, Regional smelting is carried out on the left section, the copper content in the obtained left section is 4.05%, and the finished aluminum electrolysis cathode steel rod is obtained. This m...

Embodiment 3

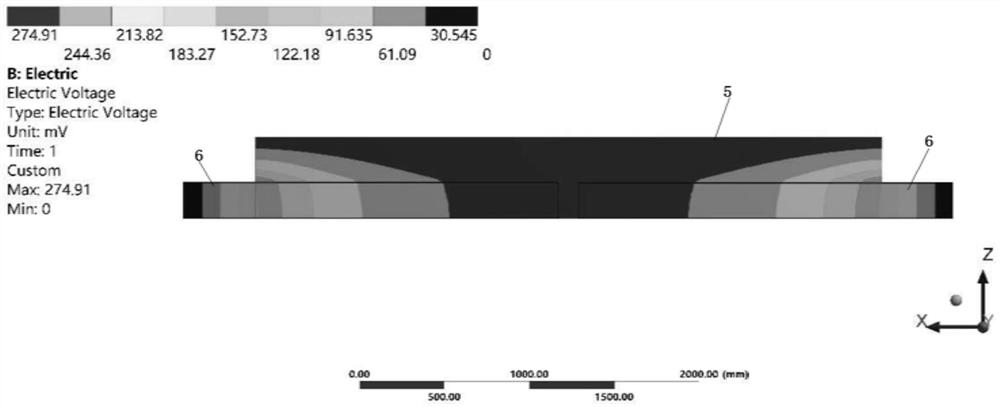

[0068] A novel aluminum electrolysis cathode steel rod and a preparation method thereof, wherein the cathode steel rod is a non-through-length steel-copper alloy rod. The steel-copper alloy rod rough billet with copper content of 6wt% is divided into figure 1 The quadrants shown, ie the first zone 1, the second zone 2, the third zone 3, and the fourth zone 4, carry out zone smelting. Melting is carried out from the end where the first section 1 of the steel-copper alloy rod rough billet is located (as the outlet end) to the other end, the melting speed is controlled at 14 cm / h, and smelting is carried out 4 times. During the first zone smelting, the smelting temperature in the melting zone was controlled at 1484°C, and the first section 1, the second section 2, the third section 3, and the fourth section 4 were sequentially smelted to obtain the fourth section 4 The copper content in the medium is 8.1wt%; during the second zone smelting, the temperature of the melting zone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com