Handcraft papermaking device

A handmade papermaking and paper trough technology, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of increasing operating difficulty and labor intensity for operators, difficulty in unifying standards, and unaffected quality of handmade paper. Standardized steps, unified quality, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

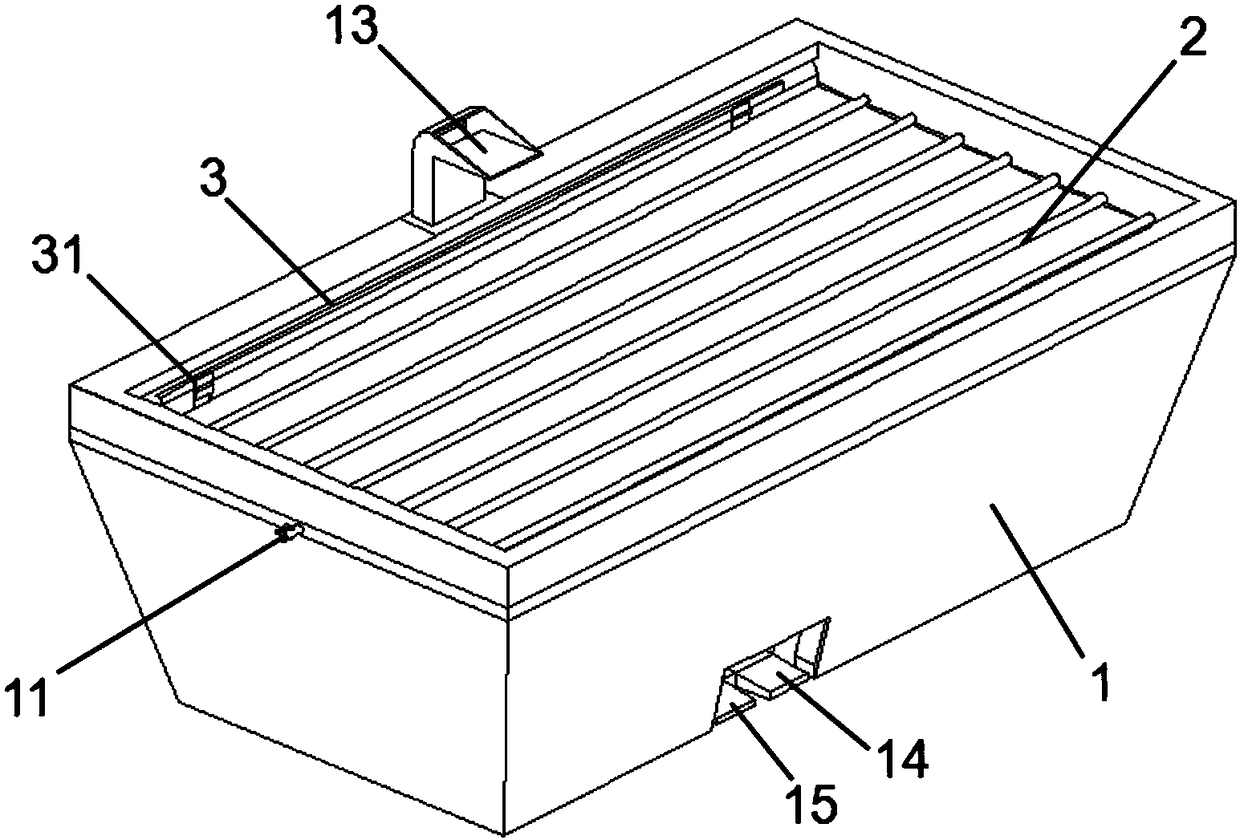

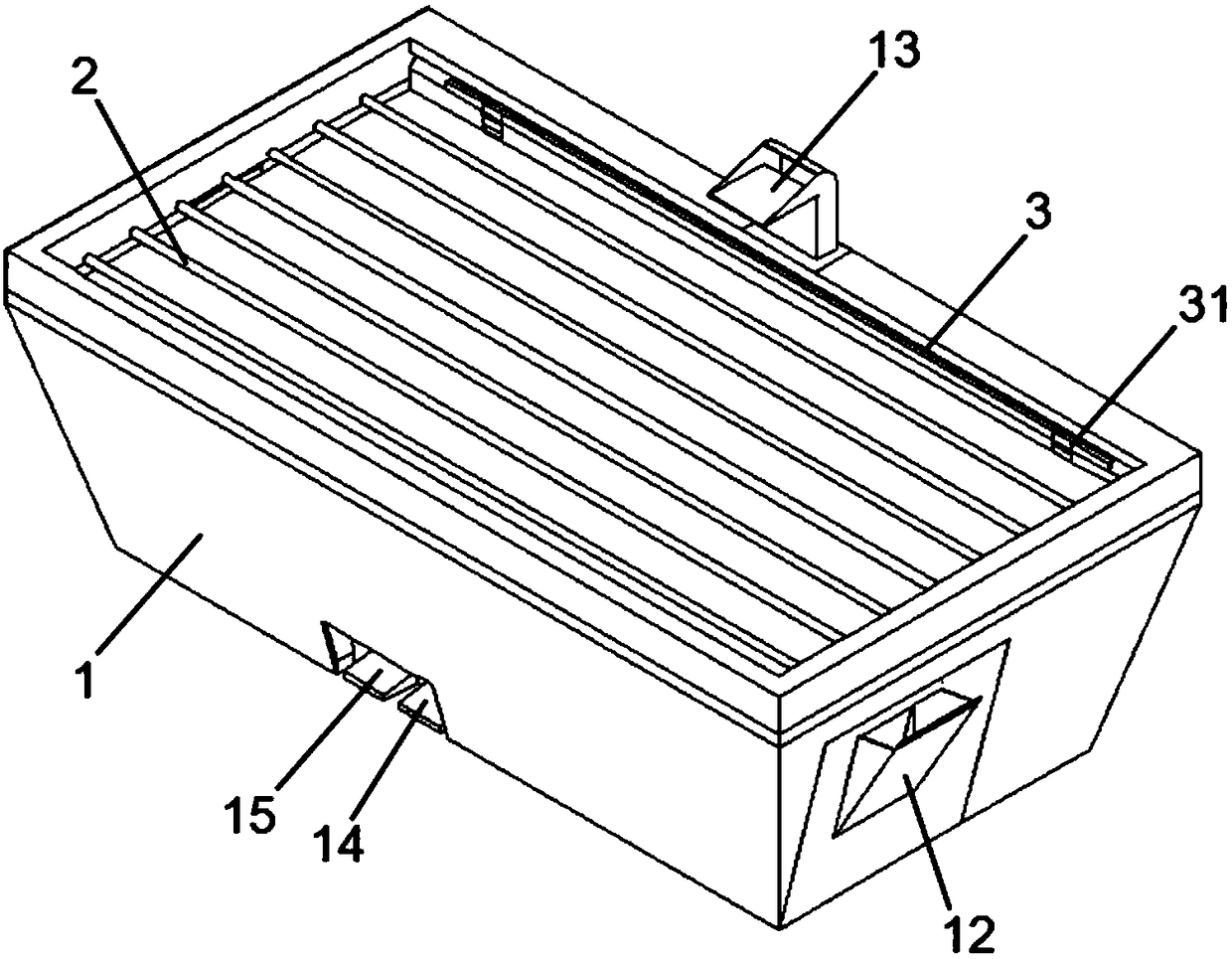

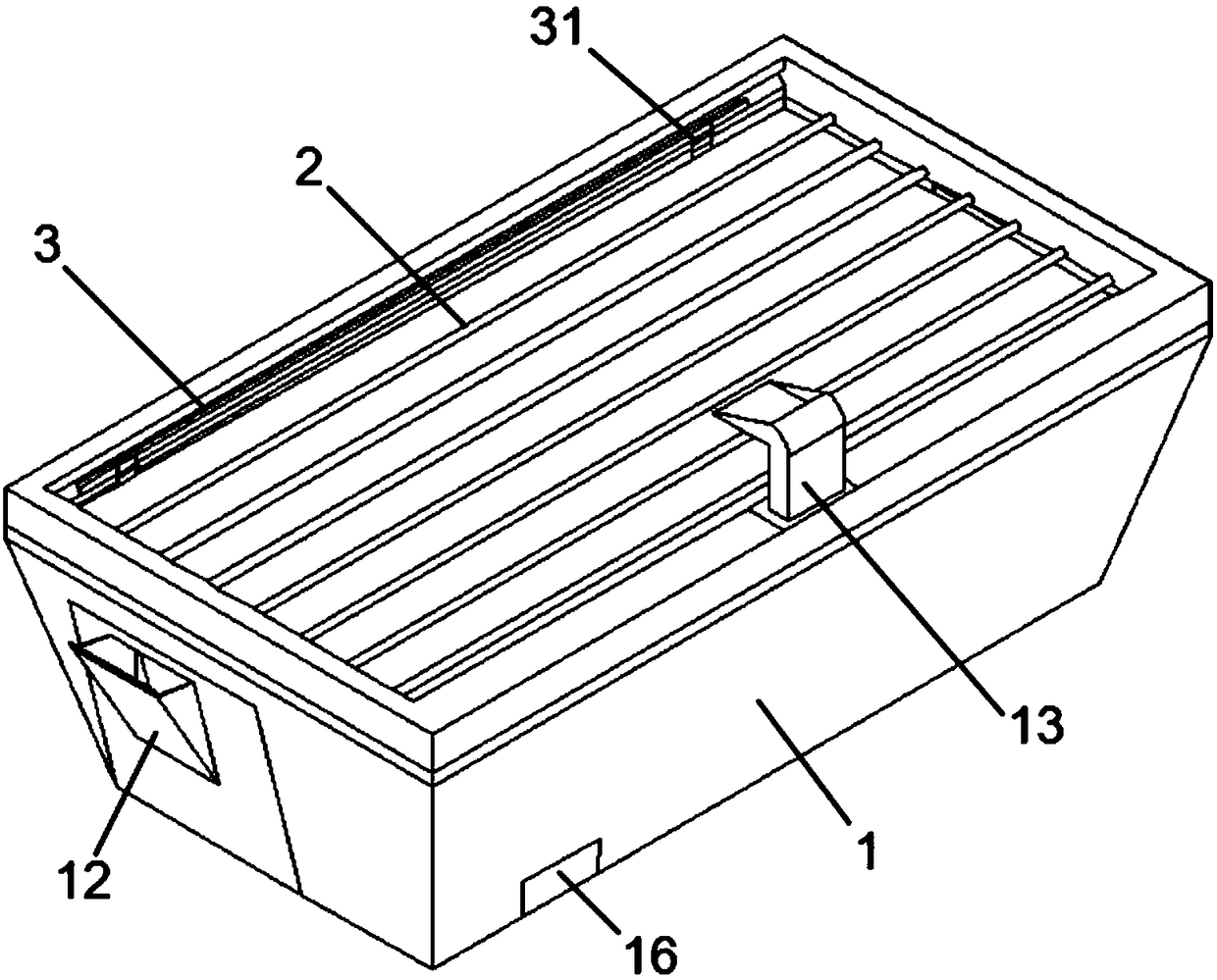

[0023] see below Figure 1 ~ Figure 4 The manual papermaking device according to the present invention will be described in detail.

[0024] The manual papermaking device of the present invention is mainly used for manual papermaking, such as Figure 1 ~ Figure 4 As shown, the handmade papermaking device mainly includes a papermaking tank 1 for accommodating the mixed solution of water and pulp, and a paper curtain 4 that is detachably connected with the papermaking tank 1 (such as Figure 4 As shown), the paper curtain supporting member for supporting the paper curtain 4, the paper curtain positioning member for realizing the detachable connection between the paper curtain 4 and the papermaking tank 1, and the water supply device and the water supply device respectively communicated with the papermaking tank 1 Pulp supply device. specifically:

[0025] The papermaking tank 1 is the main structure of the whole handmade papermaking device, which is used to hold the mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com