Gas bearing device for free piston type refrigerating machine

A gas bearing and piston type technology, applied in the field of fluid circulation equipment, can solve the problems of reduced working efficiency and motion accuracy, shortened service life of gas bearings, increased clogging of gas bearings, etc., to reduce the probability of clogging, prolong service life, prevent Reduced effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

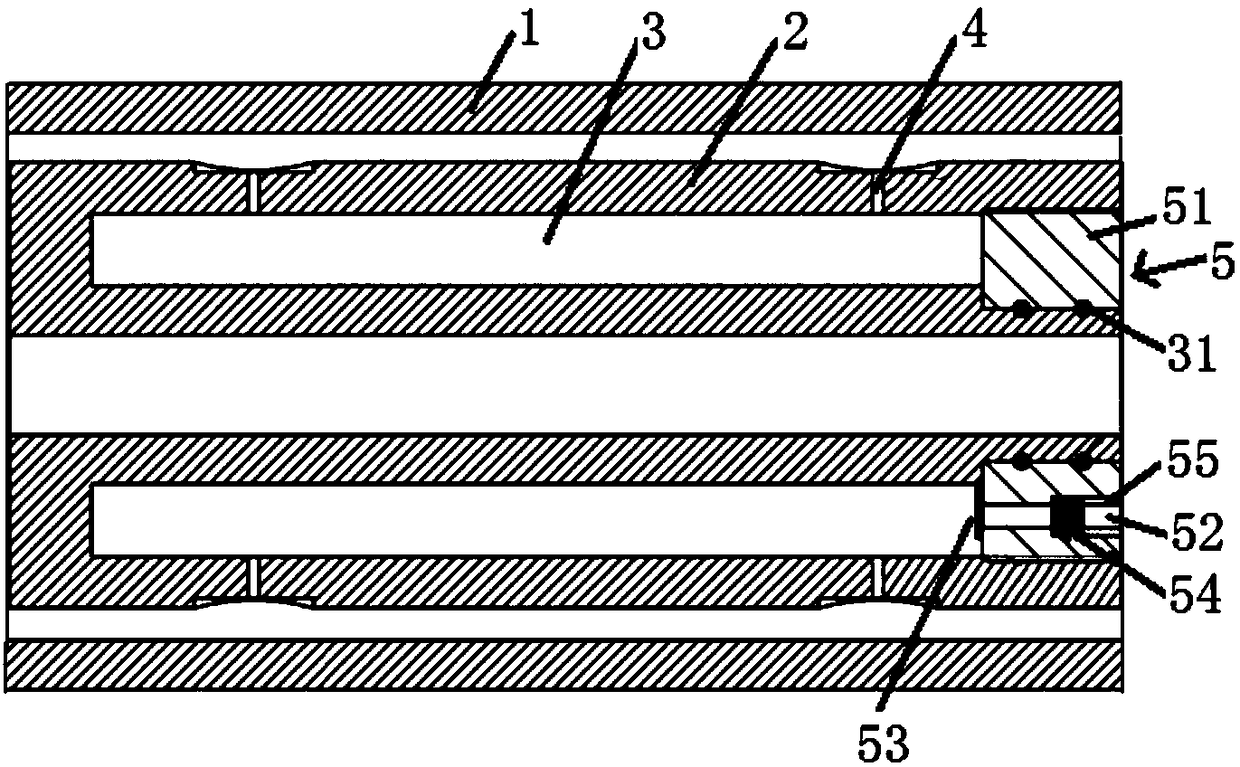

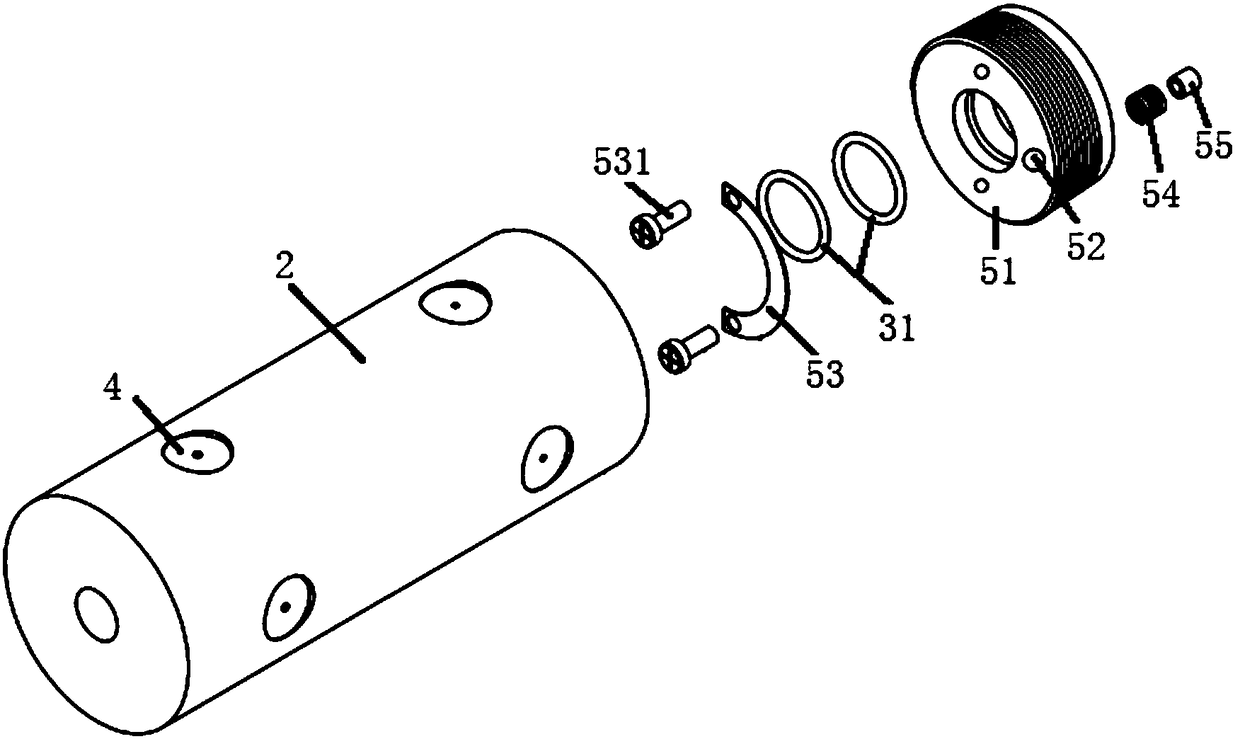

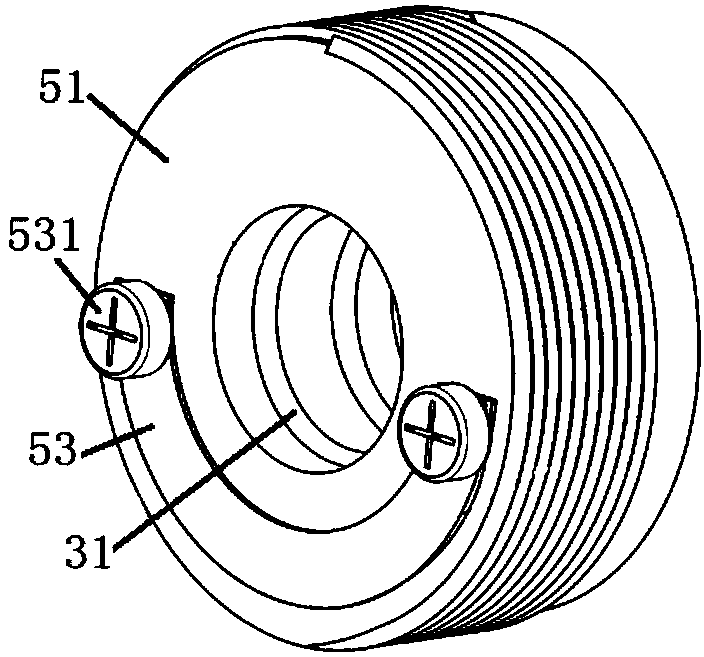

[0026] to combine Figure 1 to Figure 5 As shown, a gas bearing device for a free piston refrigerator provided in this embodiment includes a cylinder 1, a piston body 2, an air charging chamber 3, a flow limiting mechanism 4 and a one-way air intake mechanism 5, and the air charging chamber 3 is arranged inside the piston body 2, and the flow limiting mechanism 4 embedded on the outer surface of the piston body 2 communicates with the inflation chamber 3, and the side of the inflation chamber 3 close to the top of the piston body 2 passes through The one-way air intake mechanism 5 is connected to the compression chamber formed by the piston body 2 and the cylinder 1 in one row, and the one-way air intake mechanism 5 includes a valve seat 51 provided with an air inlet hole 52, which can cover the The lift self-control reed 53 of the air intake hole 52 and the filter element 54 arranged in the air intake hole 52, the two ends of the lift self-control reed 53 are fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com