A Universal Correction Method for Sensor Systems

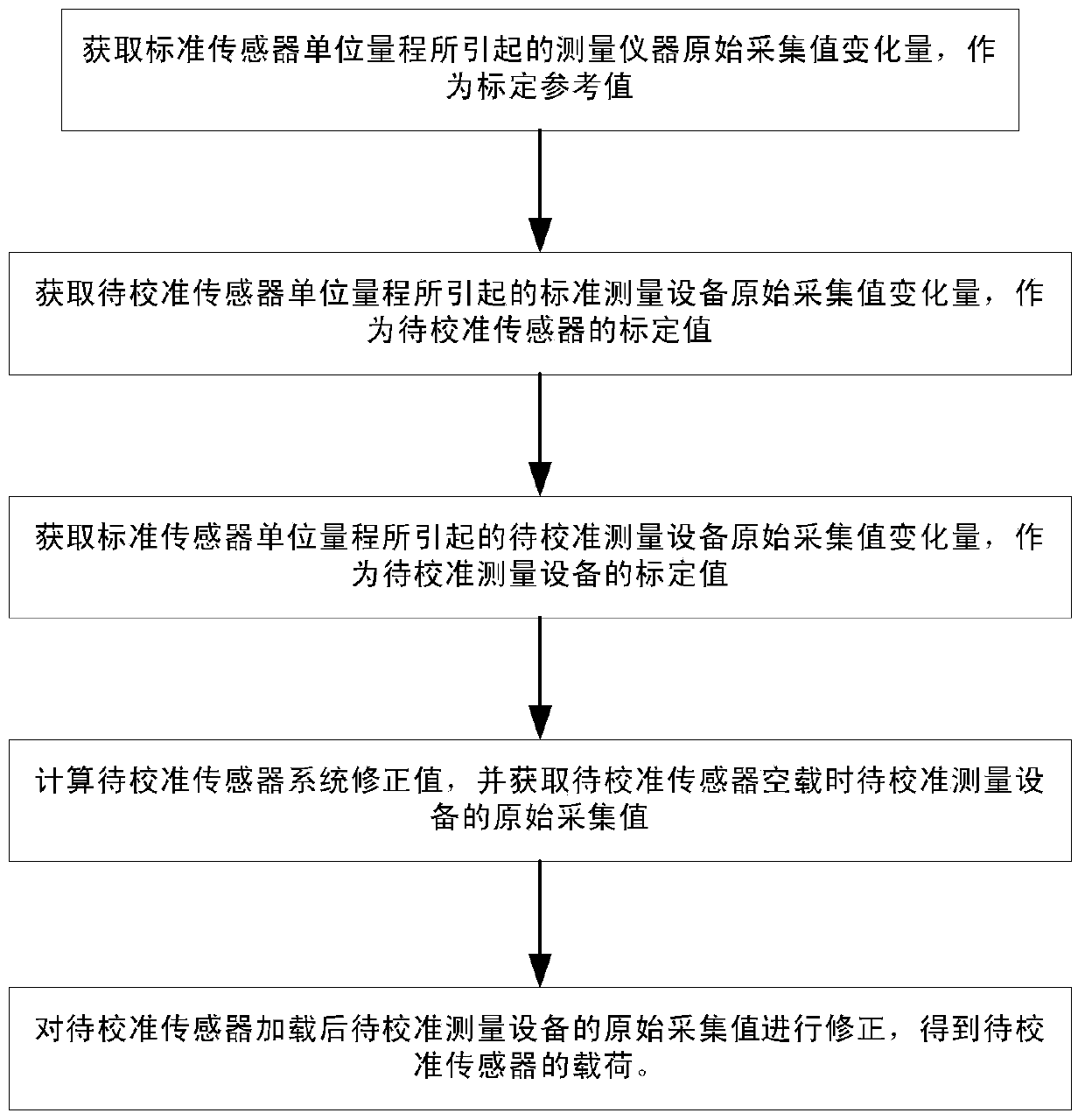

A sensor and standard sensor technology, applied in the direction of instruments, etc., can solve the problems affecting the convenience of use of the sensor, and achieve the effect of avoiding calibration work, simplifying the use process, and increasing the flexibility of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: the load cell S of different batches of the same model a ,S b Access to the same measuring device E m

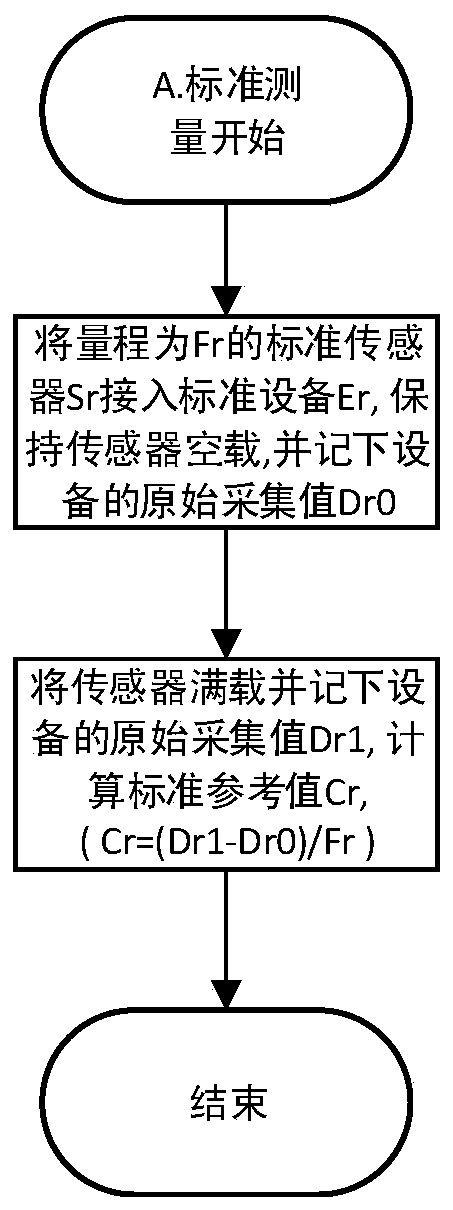

[0069] Select sensor S as standard r and measuring equipment E r , the standard sensor S r and standard measuring equipment E r connected to form a sensor system. Standard sensor S r In the case of not loading any weight, the original collection value at this time is 52.2, write down D r0 = 52.2. Standard sensor S r In the case of loading a full load of 500kg, the original collection value at this time is 5496.7, record D r1 =5496.7, get calibration reference value C r =(5496.7-52.2) / (500kg)=10.889 / kg.

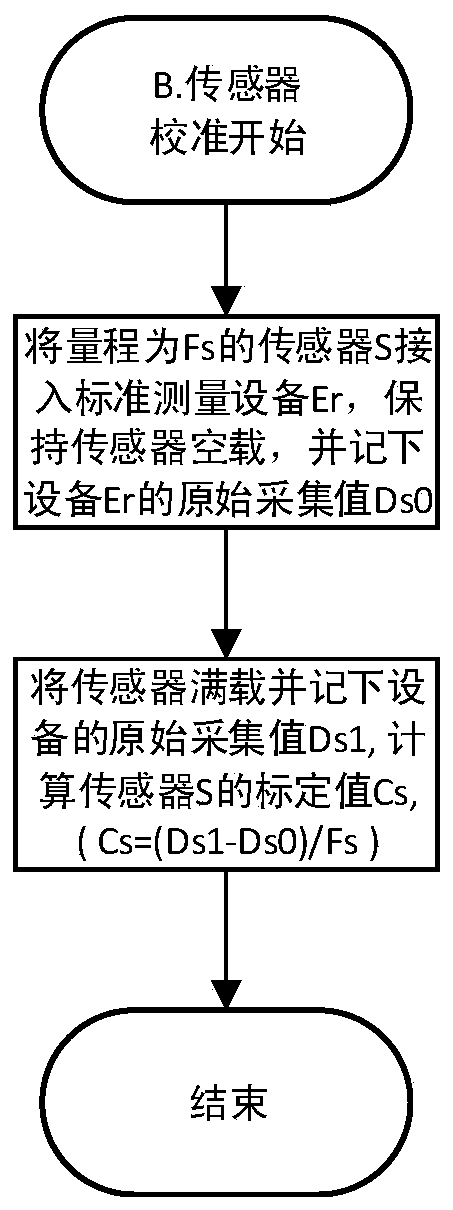

[0070] the sensor S a and standard measuring equipment E r connected to form a sensor system. Sensor S a In the case of not loading any weight, the original collection value at this time is 173.6, record D s0 = 173.6. Sensor S a In the case of loading a full load of 7kg, the original collection value at this time is 8163.8, record D s...

Embodiment 2

[0075] Embodiment 2: the same type of load cell S without range a ,S c Access to the same measuring device E m

[0076] the sensor S c and standard measuring equipment E r connected to form a sensor system. Sensor S c In the case of not loading any weight, the original collection value at this time is 181.6, write down D s0 = 181.6. Sensor S c In the case of loading a full load of 20t, the original collection value at this time is 10347.8, record D s1 =10347.8, calculate S c The calibration reference value C sc =(10347.8-181.6) / (20t)=508.31 / t.

[0077] When sensor S a and measuring equipment E m When connected to form a sensor system, the system correction value C a =(1141.5 / kg)·(6.7304 / kg) / (10.889 / kg)=705.55 / kg, system correction relationship The unit is kg. ,

[0078] When sensor S c and measuring equipment E m When connected to form a sensor system, the system correction value C c =(508.31 / t)·(6.7304 / kg) / (10.889 / kg)=314.18 / t, system correction relations...

Embodiment 3

[0079] Embodiment 3: load cell S a , temperature sensor S d Access to the same measuring device E m

[0080] The temperature sensor S d and standard measuring equipment E r connected to form a sensor system. temperature sensor d At 0°C, the original collection value is -72.3, write down D s0 =-72.3. temperature sensor d When loaded to 100°C, the original collection value is 9382.4, write down D s1 =9382.4, calculated temperature sensor S d Calibration reference value C′ s =(9382.4+72.3) / (100°C)=94.547 / °C).

[0081] When sensor S a and measuring equipment E m When connected to form a sensor system, the system correction value C a =(1141.5 / kg)·(6.7304 / kg) / (10.889 / kg)=705.55 / kg, system correction relationship The unit is kg. , the system corrects the relation,

[0082] When the temperature sensor S d and measuring equipment E m When connected to form a sensor system, the system correction value C d =(94.547 / ℃)·(6.7304 / kg) / (10.889kg)=58.439 / ℃ / , system correcti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com