A sampling machine control method and device

A control method and sampling machine technology, applied in the direction of sampling device, computer control, program control, etc., can solve the problems of increased descending resistance, slow motor speed, drilling through the chassis of the carriage, etc., so as to improve safety, ensure safety, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

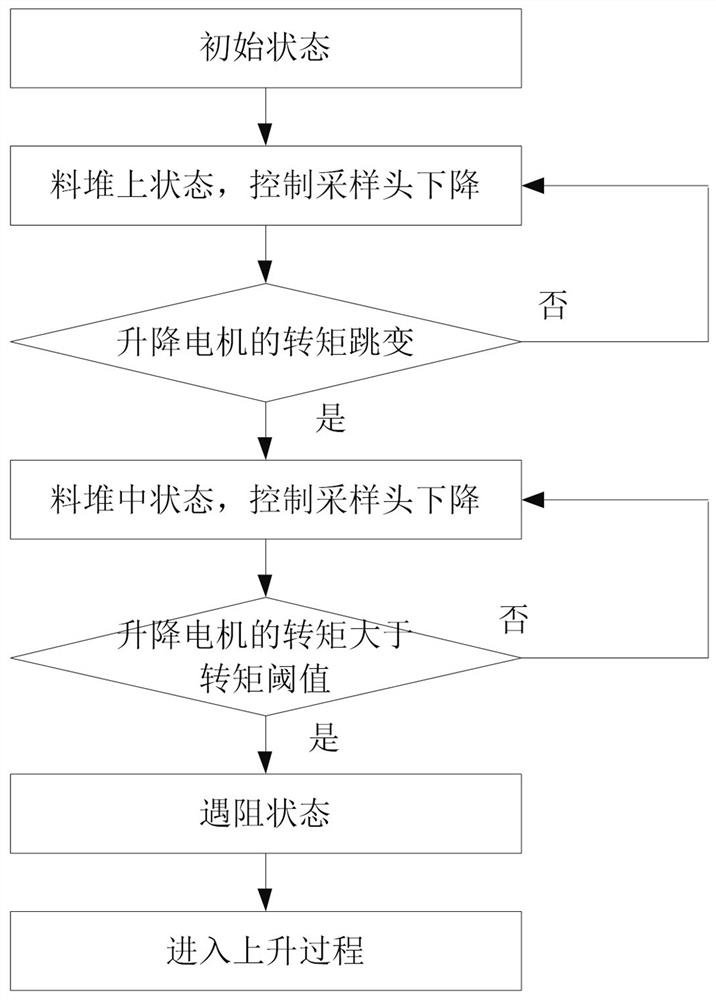

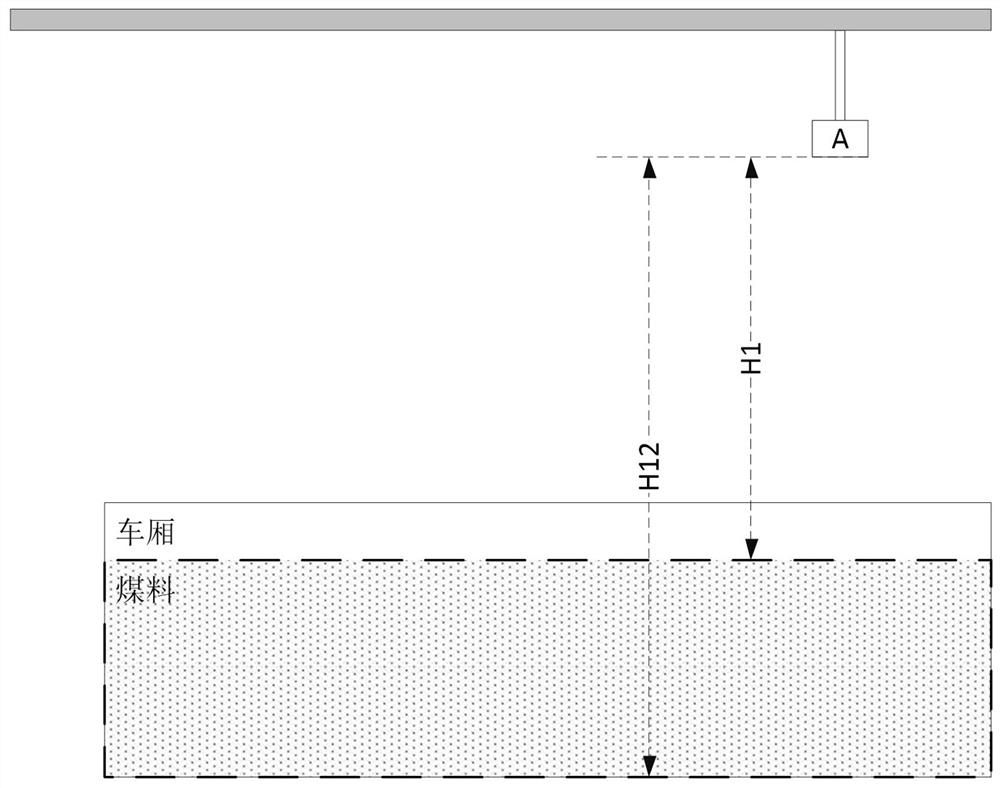

[0021] Such as figure 1 As shown, the sampling machine control method of this embodiment determines the position state of the sampling head according to the torque of the lifting motor during the descending process of the sampling head, and determines the descending speed of the lifting motor and the rotation speed of the rotating motor according to the position state.

[0022] In this embodiment, the position state includes the state on the stockpile, the state in the stockpile and the blocked state; when the torque belongs to the preset first torque interval, it is judged that the position state of the sampling head is the state on the stockpile; When the state of the material pile is on, when the torque jumps, it is judged that the position state of the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com