Piezoelectric electret material assembly, preparation method and application

A technology of piezoelectric electret and components, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve problems such as inability to achieve grounding, and achieve structural The effect of simplicity, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

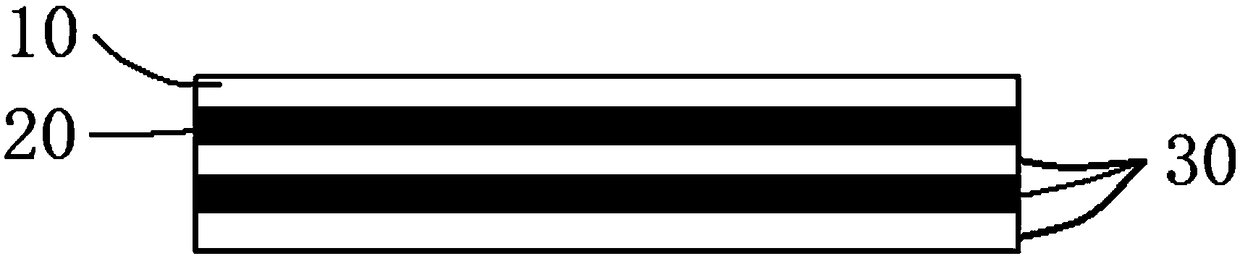

[0028] figure 1 It is the front view of the composite layer of the piezoelectric electret sensor in the first embodiment.

[0029] Such as figure 1 As shown, the composite layer of the piezoelectric electret sensor includes: an insulating layer 10 , a metal ground layer 20 and a piezoelectric electret material assembly 30 arranged in sequence.

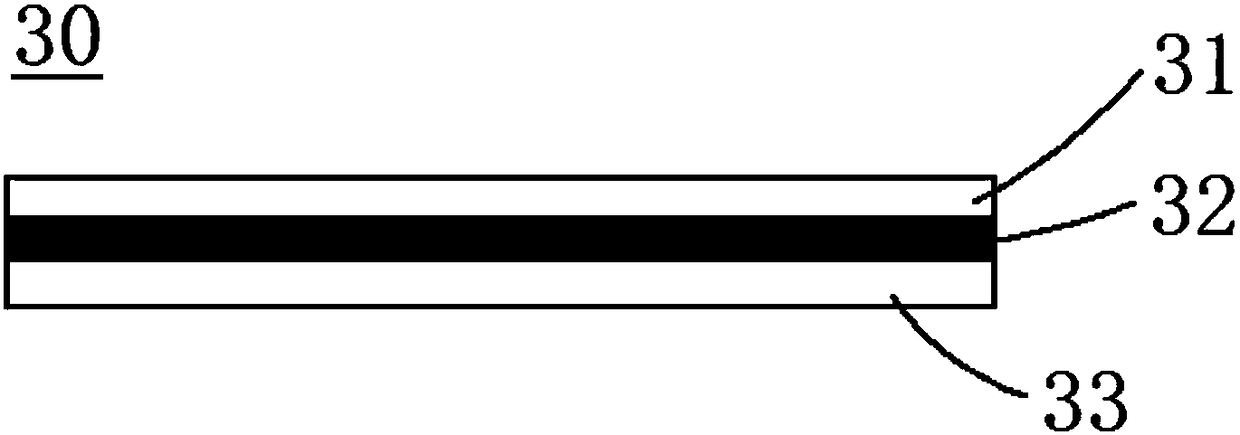

[0030] figure 2 It is the front view of the piezoelectric electret material assembly of the first embodiment.

[0031] Such as figure 2 As shown, the piezoelectric electret material assembly 30 includes: a piezoelectric electret layer 31 , a metal positive electrode layer 32 and an insulating layer 33 arranged in sequence.

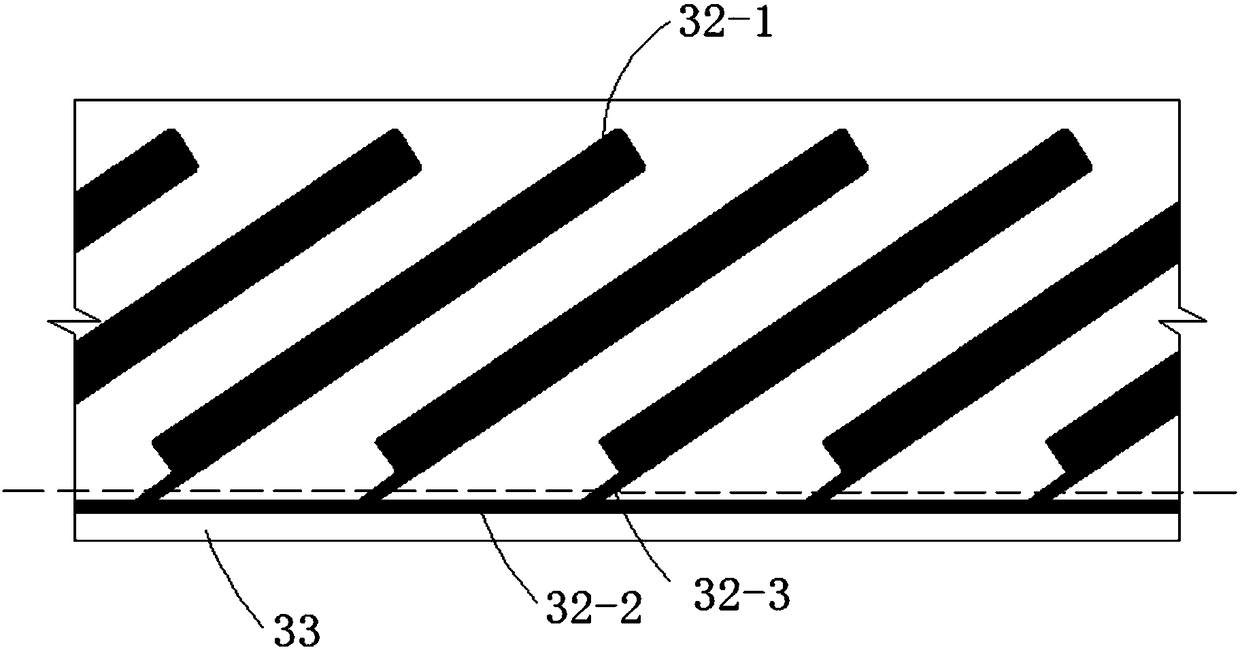

[0032] image 3 It is a top view of the metal positive electrode layer and the insulating layer of the first embodiment.

[0033] Such as image 3 As shown, the metal positive electrode layer 32 includes: several independent and repeated metal electrode units 32-1, connecting electrodes 32-2 and pins 32-3 ...

Embodiment 2

[0049] Figure 5 It is the front view of the composite layer of the piezoelectric electret sensor in the second embodiment.

[0050] Such as Figure 5 As shown, the composite layer of the piezoelectric electret sensor includes: an insulating layer 10 , a metal ground layer 20 , a piezoelectric electret material assembly 30 , a metal ground layer 40 and an insulating layer 50 arranged in sequence.

[0051] Figure 6 It is the front view of the piezoelectric electret material assembly of the second embodiment.

[0052] Such as Figure 6 As shown, the piezoelectric electret material assembly 30 includes: a piezoelectric electret layer 31 , a metal positive electrode layer 32 and an insulating layer 33 arranged in sequence.

[0053] Figure 7 It is a top view of the metal positive electrode layer and the insulating layer of the second embodiment.

[0054] Such as Figure 7 As shown, the metal positive electrode layer 32 includes: several independent and repeated metal elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com