Miniature rectangular high-voltage electrical connector

A technology of high-voltage electricity and connectors, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of cracking at the junction of the shell and the potting sleeve, failure to meet the design requirements, and cumbersome assembly procedures, etc., to achieve environmental adaptation Improved performance, reduced occupied space, and reduced installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

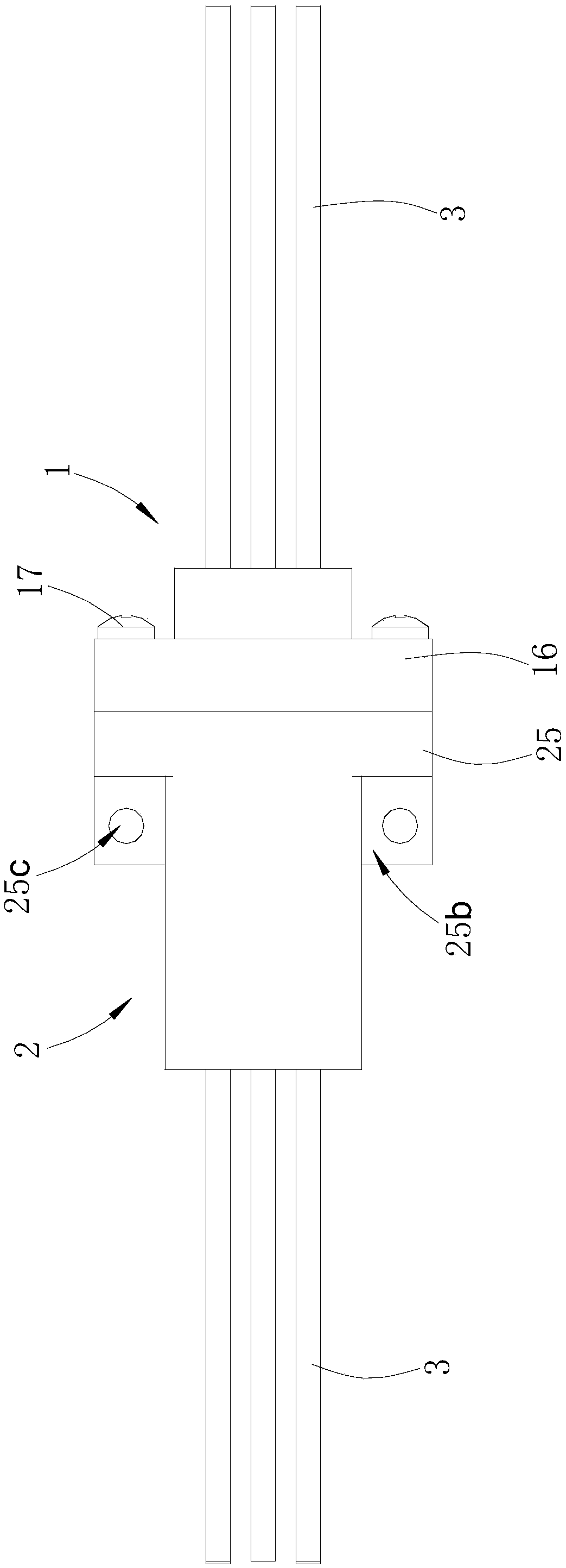

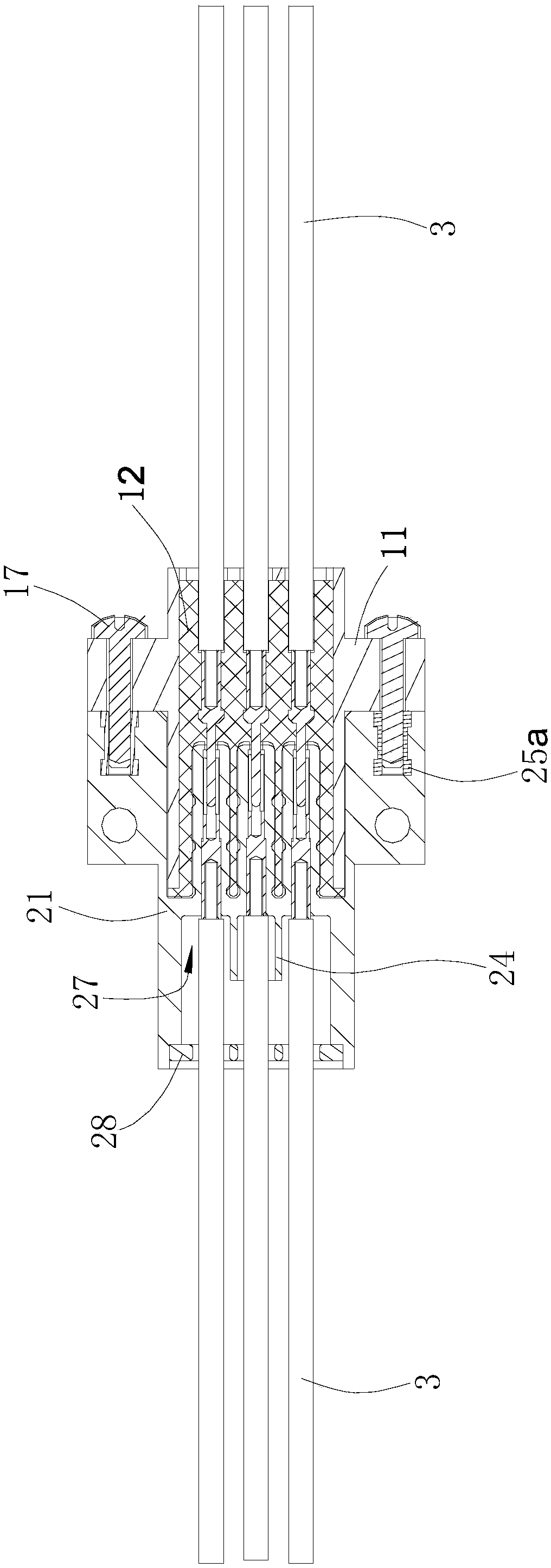

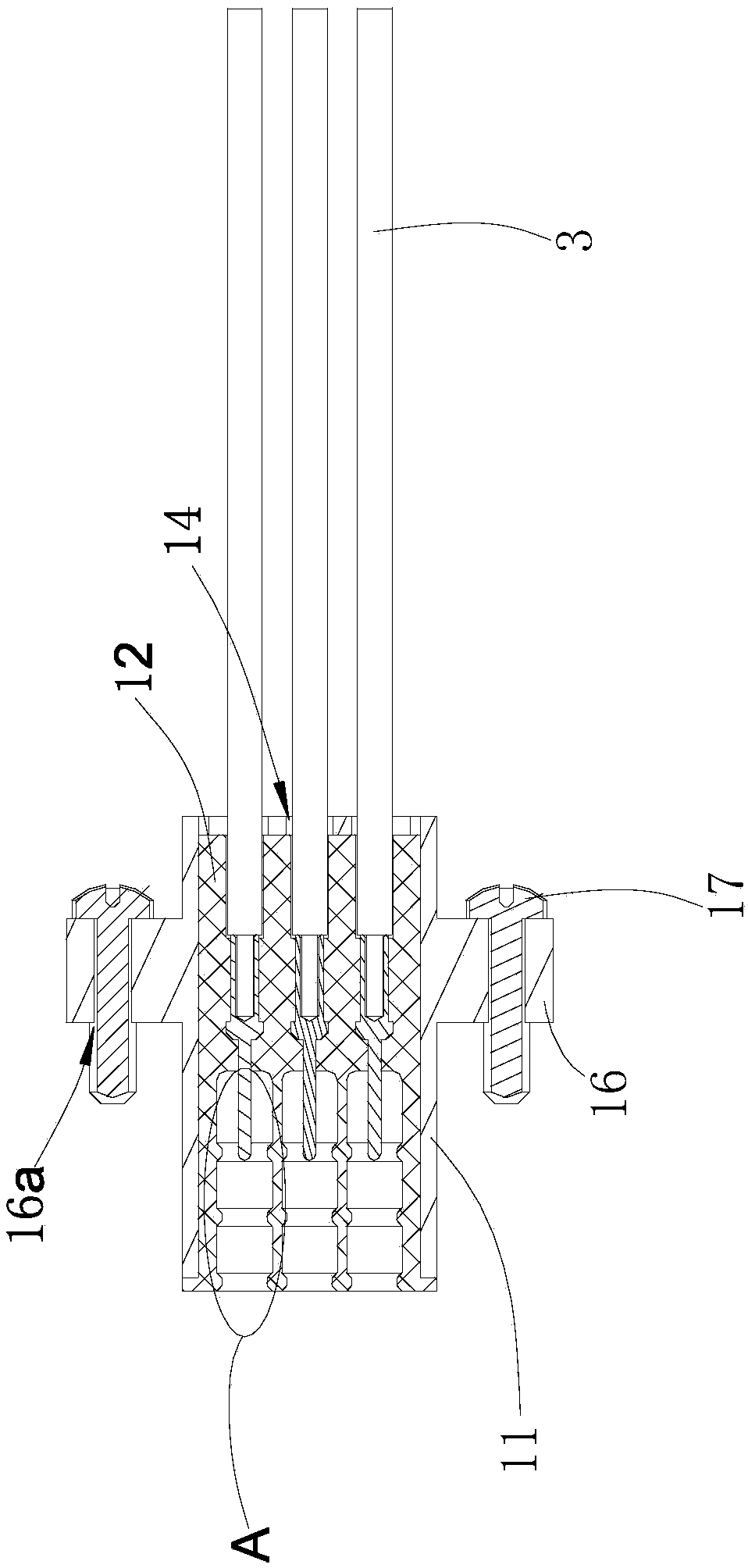

[0025] Such as Figures 1 to 6 as shown,

[0026] The electrical connector includes a socket 1 and a plug 2 adapted to the socket 1 .

[0027] The socket 1 includes a hollow socket housing 11, a soft board 12, and a metal pin 15. The housing 11 is made of insulating material, and the housing 11 is set on the outside of the soft board 12. The material of the soft board 12 is In order to resist low temperature silicone rubber, the installation soft board 12 and the socket housing 11 are sealed and bonded with silicone rubber 3040. The socket housing 11 can reliably hold the insulating installation board. There are six sockets at the rear of the installation soft board 12. The barrel groove 13 and the inserting barrel groove 13 are arranged in two rows in a rectangular shape. There are four sealing convex rings 13a extending inward on the side wall of each inserting barrel groove 13; Groove 14, wire groove 14 and inserting socket groove 13 one-to-one correspondence, is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com