Composite stack-up release film and preparation method thereof

A release film and composite technology, applied in the direction of chemical instruments and methods, printed circuit manufacturing, synthetic resin layered products, etc., to achieve the effects of reasonable formula, reduced process and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

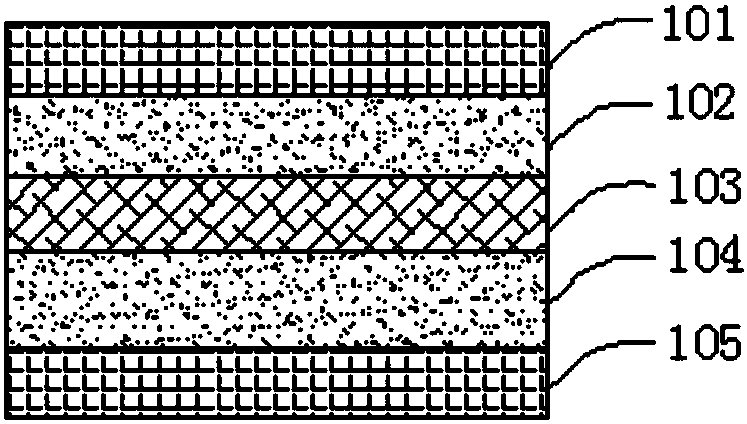

[0052] Embodiment 1: A kind of composite laminated release film 100, such as image 3 As shown, it includes an intermediate layer 103, a release layer and a buffer layer whose hardness is lower than that of the intermediate layer 103;

[0053]The intermediate layer 103 is a PE (polyethylene) layer; the intermediate layer 103 has opposite upper and lower surfaces;

[0054] The buffer layer has two layers and is respectively an upper buffer layer 102 and a lower buffer layer 104, and the upper buffer layer 102 and the lower buffer layer 104 are respectively formed on the upper and lower surfaces of the middle layer 103;

[0055] The release layer has two layers and is respectively an upper release layer 101 and a lower release layer 105, and both the upper release layer 101 and the lower release layer 105 are TPX (poly-4-methylpentene) layer; the upper release layer 101 is formed on the upper surface of the upper buffer layer 102, and the upper buffer layer 102 is bonded to the...

Embodiment 2

[0069] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated. The difference is that the middle layer 103 is a PET (polyethylene terephthalate) layer.

[0070] Both the upper buffer layer 102 and the lower buffer layer 104 are made of the following materials (by weight): TPX is 40%; PE is 0%; PP is 20%; EMMA is 40%.

[0071] The thickness of the middle layer is 30 μm, the thickness of the upper buffer layer is 20 μm, the thickness of the lower buffer layer is 60 μm, the thickness of the upper release layer is 20 μm, and the thickness of the lower release layer is 30 μm .

Embodiment 3

[0072] Embodiment 3: The structure of this embodiment is the same as that of Embodiment 1 and will not be repeated. The difference is that the middle layer 103 is a PP layer.

[0073] The upper buffer layer 102 and the lower buffer layer 104 are all made of the following raw materials (by weight): TPX is 30%; PE is 40%; PP is 20%; EMA (ethylene-methyl acrylate copolymer ) is 10%.

[0074] The thickness of the middle layer is 35 μm, the thickness of the upper buffer layer is 50 μm, the thickness of the lower buffer layer is 50 μm, the thickness of the upper release layer is 20 μm, and the thickness of the lower release layer is 20 μm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com