Ejection-out type heat radiating device and electronic calculation equipment

A heat dissipation device and pop-up technology, which is applied in the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., can solve the problems of increased radiator volume, loud noise, and high cost, and achieve increased convection speed, The effect of increasing heat dissipation efficiency and increasing heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

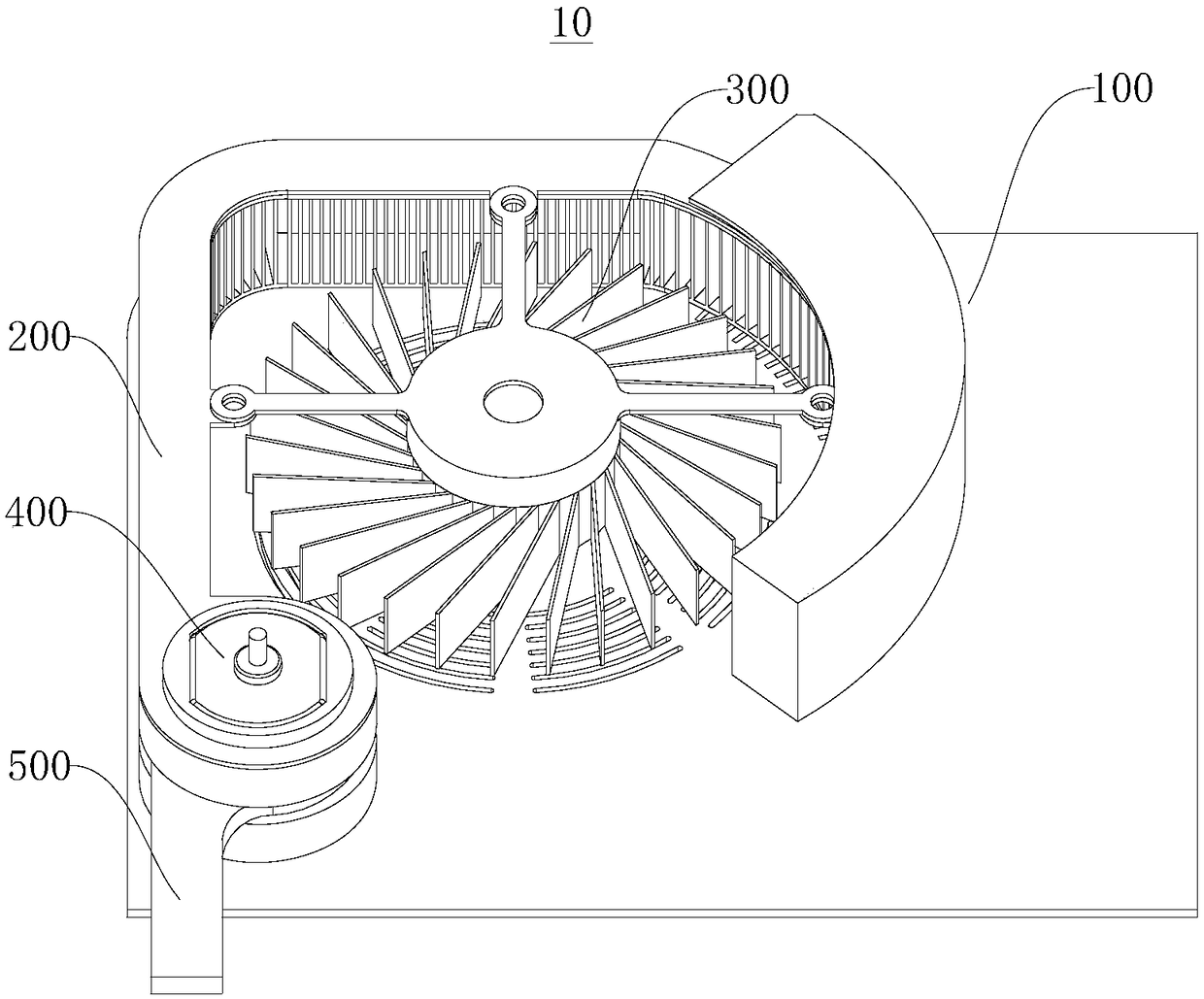

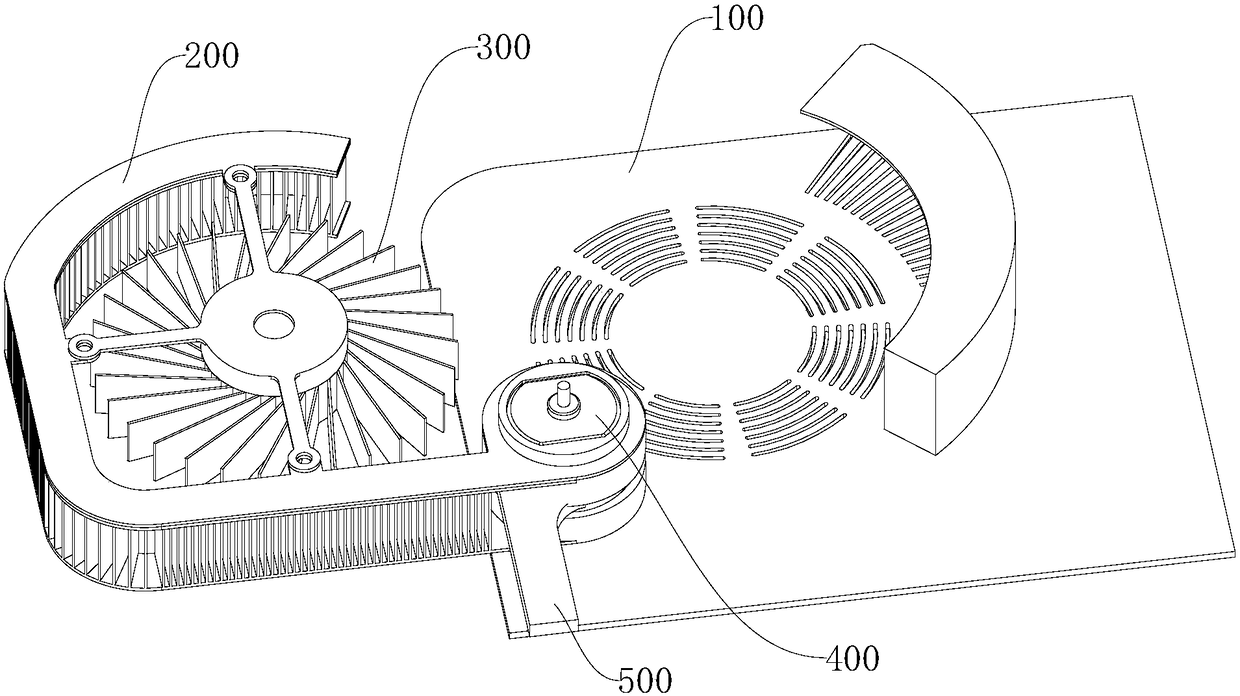

[0042] see figure 1 with figure 2 , this embodiment provides a pop-up heat sink 10, which has the characteristics of simple structure, convenient use, large heat dissipation area and high heat dissipation efficiency, and can adjust the heat dissipation efficiency according to the real-time temperature to further effectively dissipate heat.

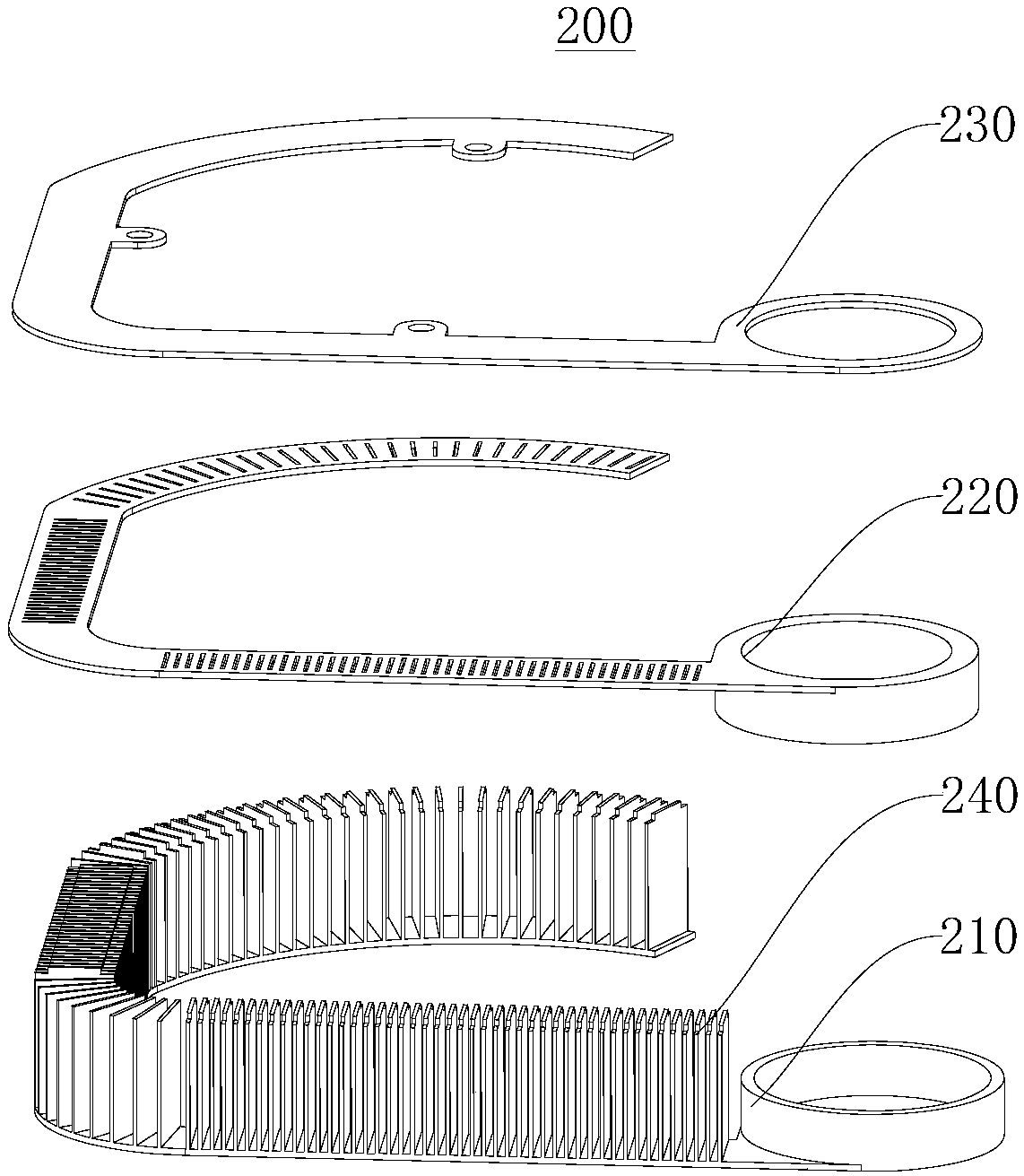

[0043] A pop-up heat dissipation device 10 provided in this embodiment includes a base 100 , a heat dissipation assembly 200 , a fan assembly 300 and a rotation assembly 400 . The rotating assembly 400 is connected with the base 100 . The fan assembly 300 is connected to the cooling assembly 200, and the cooling assembly 200 is connected to the rotating assembly 400, so that the cooling assembly 200 and the fan assembly 300 can rotate from the first position to the second position or from the second position driven by the rotating assembly 400 to the first position.

[0044] It should be noted that, in this embodiment, the first positi...

no. 2 example

[0080] Please refer to Figure 1 to Figure 12 , this embodiment provides an electronic computing device (not shown in the figure), including a housing (not shown in the figure) and the pop-up heat sink 10 as provided in the first embodiment. The pop-up heat sink 10 includes a base 100 , a heat sink assembly 200 , a fan assembly 300 and a rotating assembly 400 . The rotating assembly 400 is connected with the base 100 . The fan assembly 300 is connected to the heat dissipation assembly 200, and the heat dissipation assembly 200 is connected to the rotation assembly 400, so that the heat dissipation assembly 200 and the fan assembly 300 can rotate from the first position to the second position or from the second position driven by the rotation assembly 400 to the first position.

[0081] It should be noted that the electronic computing equipment provided in this embodiment includes, but is not limited to: a server, a personal computer, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com