Soybean milk making machine

A soymilk maker and machine head technology, which can be used in home appliances, applications, kitchen utensils, etc. It can solve the problems of large noise, high pressure, and easy resonance of food processing machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

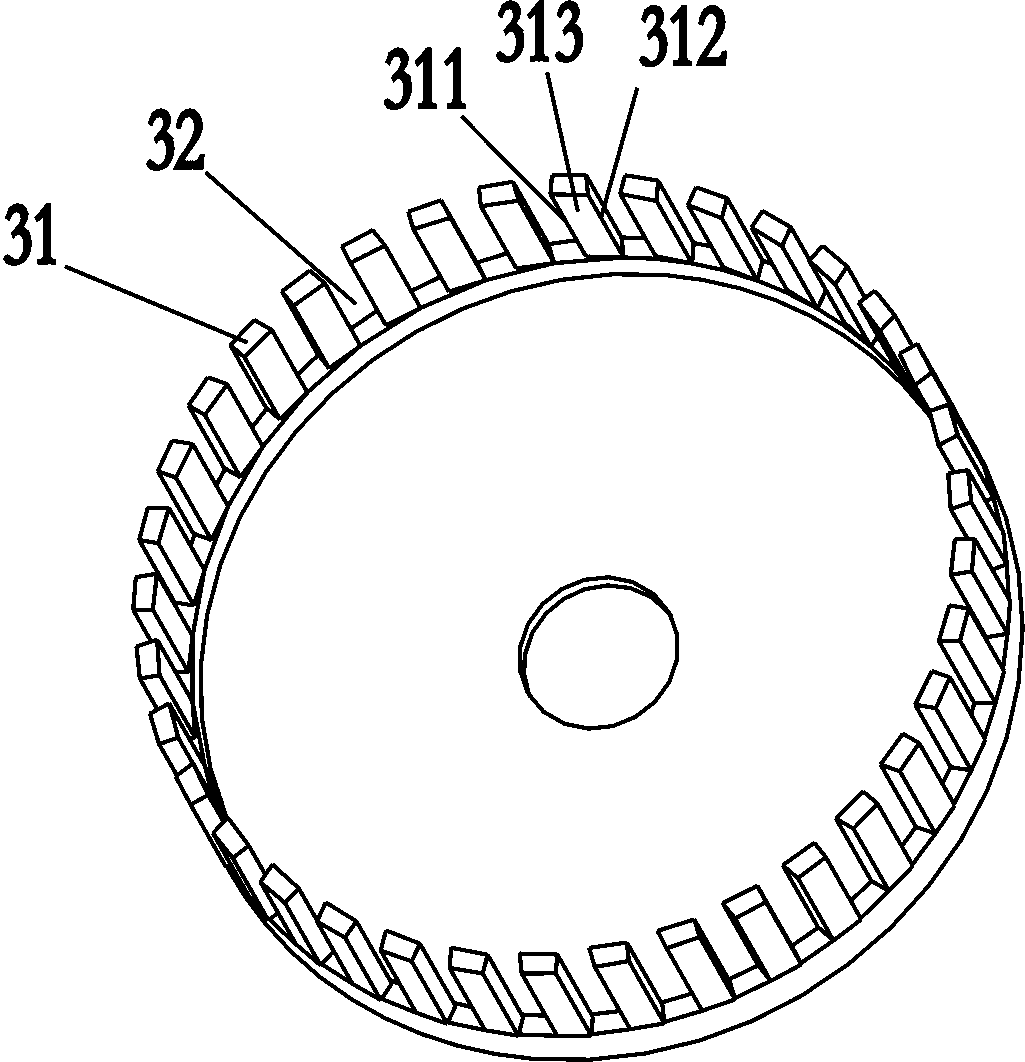

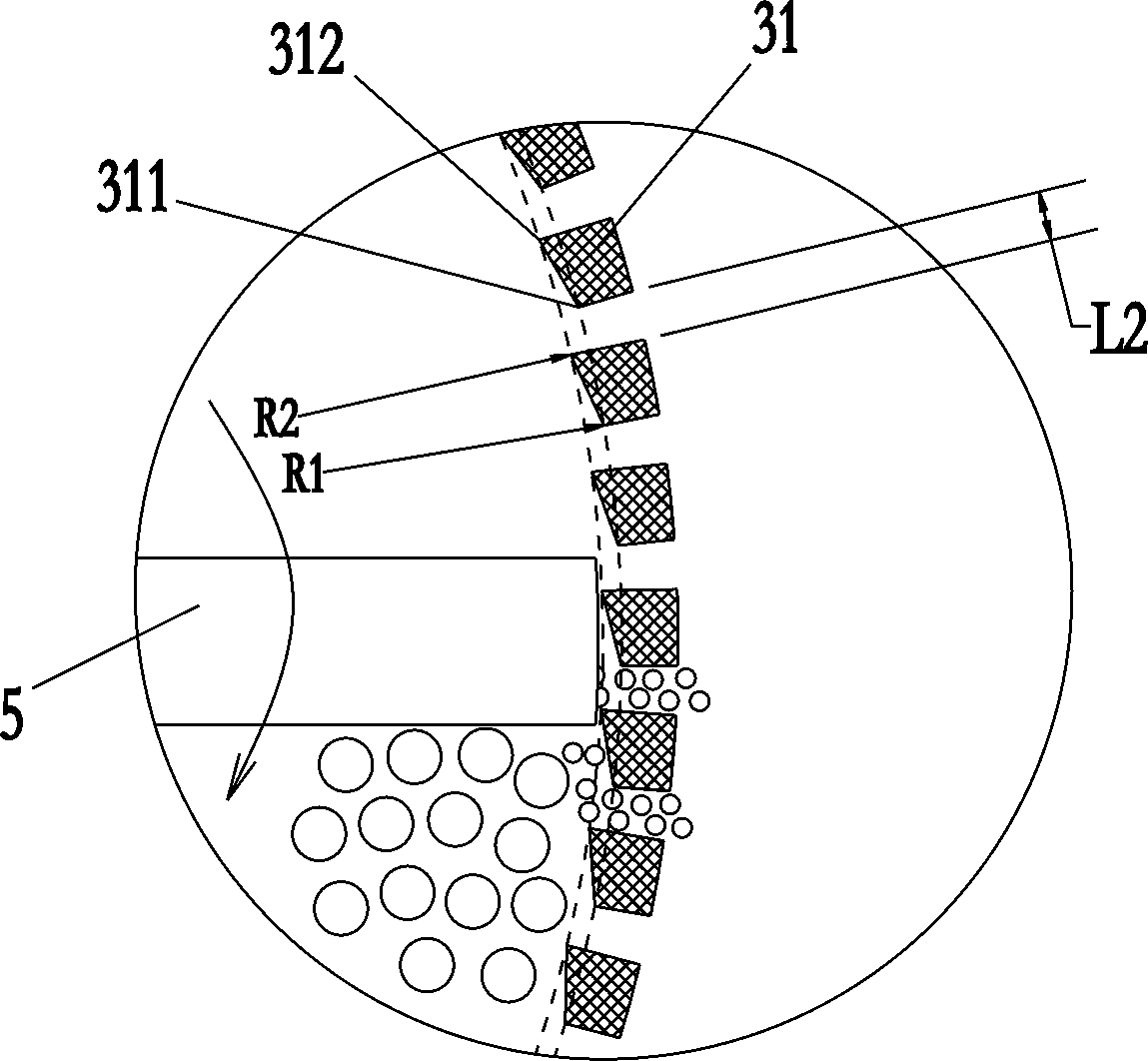

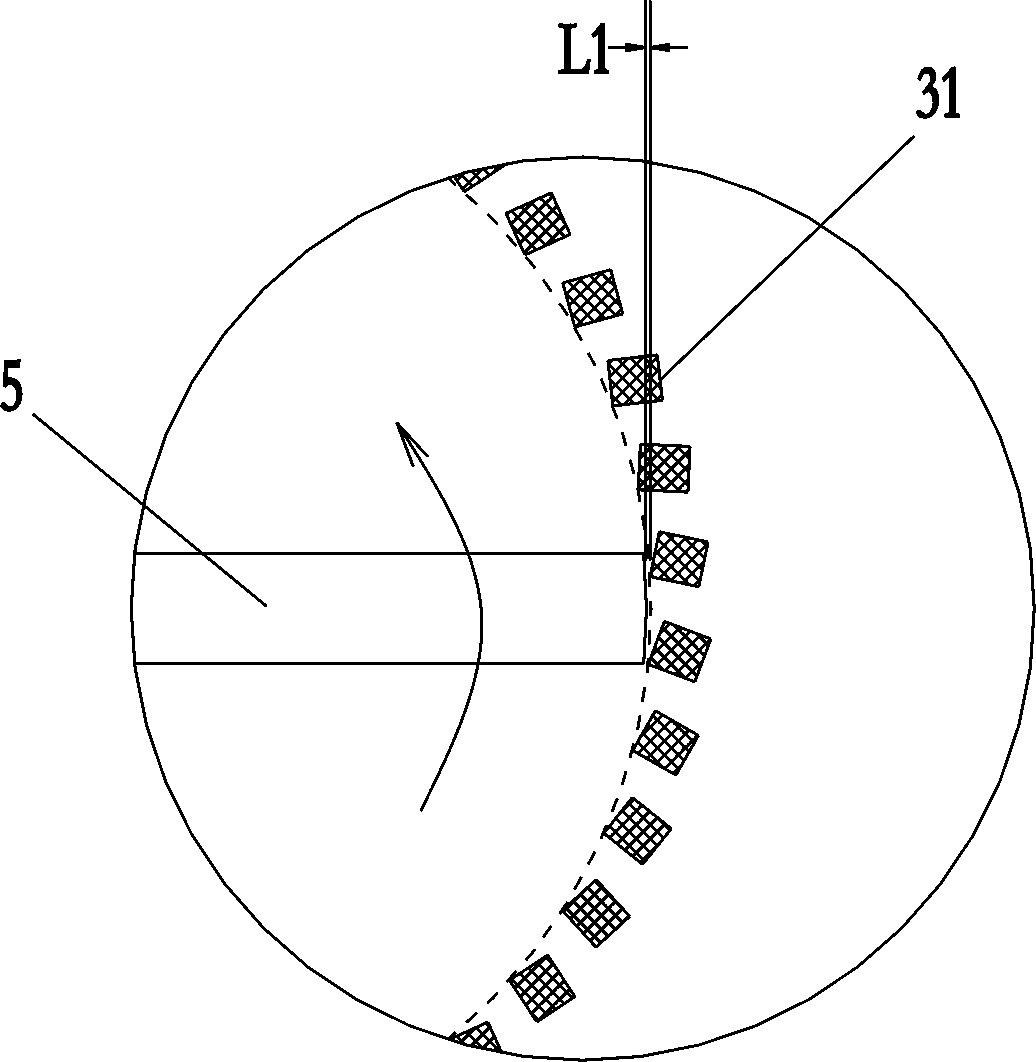

[0033] Such as figure 1 , figure 2 , image 3Shown is a schematic structural diagram of the first embodiment of the present invention. A soybean milk machine, comprising a machine head 1 and a cup body 2, the front end of the machine head is provided with a crushing cover 3, and a motor 4 is arranged in the machine head, and a crushing blade 5 is installed at the end of a rotating shaft 41 driven by the motor 4. The crushing blade 5 is located in the crushing cover 3, the bottom of the crushing cover 3 is open, and the peripheral wall of the crushing cover 3 has a plurality of baffles 31 extending toward the bottom of the cup body 2, and a discharge plate 31 is formed between adjacent baffles 31. The hole 32 is located in the crushing cover. The single baffle 31 has a first edge 311, a second edge 312 and a baffle surface 313 connecting the first edge 311 and the second edge 312. On the same horizontal section, Taking the center of the rotating shaft 41 as the center, the ...

Embodiment 2

[0048] Such as Figure 5 , Figure 6 , Figure 7 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the pulverizing blade 5 includes multiple blades, and a single blade has a transverse cutting portion 51 and a grinding blade integrated with the cutting portion 51. The grinding part 52 is located at the edge of the cutting part and is bent downward relative to the cutting part 51 , and the grinding part 52 and the spoiler 31 form grinding and pulverization. In addition, a skirt 33 connecting the baffle 31 is provided at the bottom of the baffle 31 , and the bottom of the skirt 33 is flared outwards, which facilitates the slurry at the bottom of the cup to be sucked into the crushing cover.

[0049] In this embodiment, the pulverizing blade has two symmetrical blades, and the blade 511 on the cutting part extends to the grinding part 52, wherein the gri...

Embodiment 3

[0053] Such as Figure 8 , Figure 9 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and the second embodiment is that: in this embodiment, the bottom of the crushing cover is also provided with a skirt 33 connected to the spoiler 31, and the inner wall of the skirt 33 is provided with grinding teeth 331 , the grinding portion 52 extends to the skirt 33 and forms grinding and crushing with the grinding teeth 331 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com