Automatic nut spot welding device

An automation device and nut technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of difficulty in adapting to large-scale production, safety of nut hand being crushed, and low precision of dimensional tolerance, so as to eliminate finger crushing , to ensure stability, precision, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

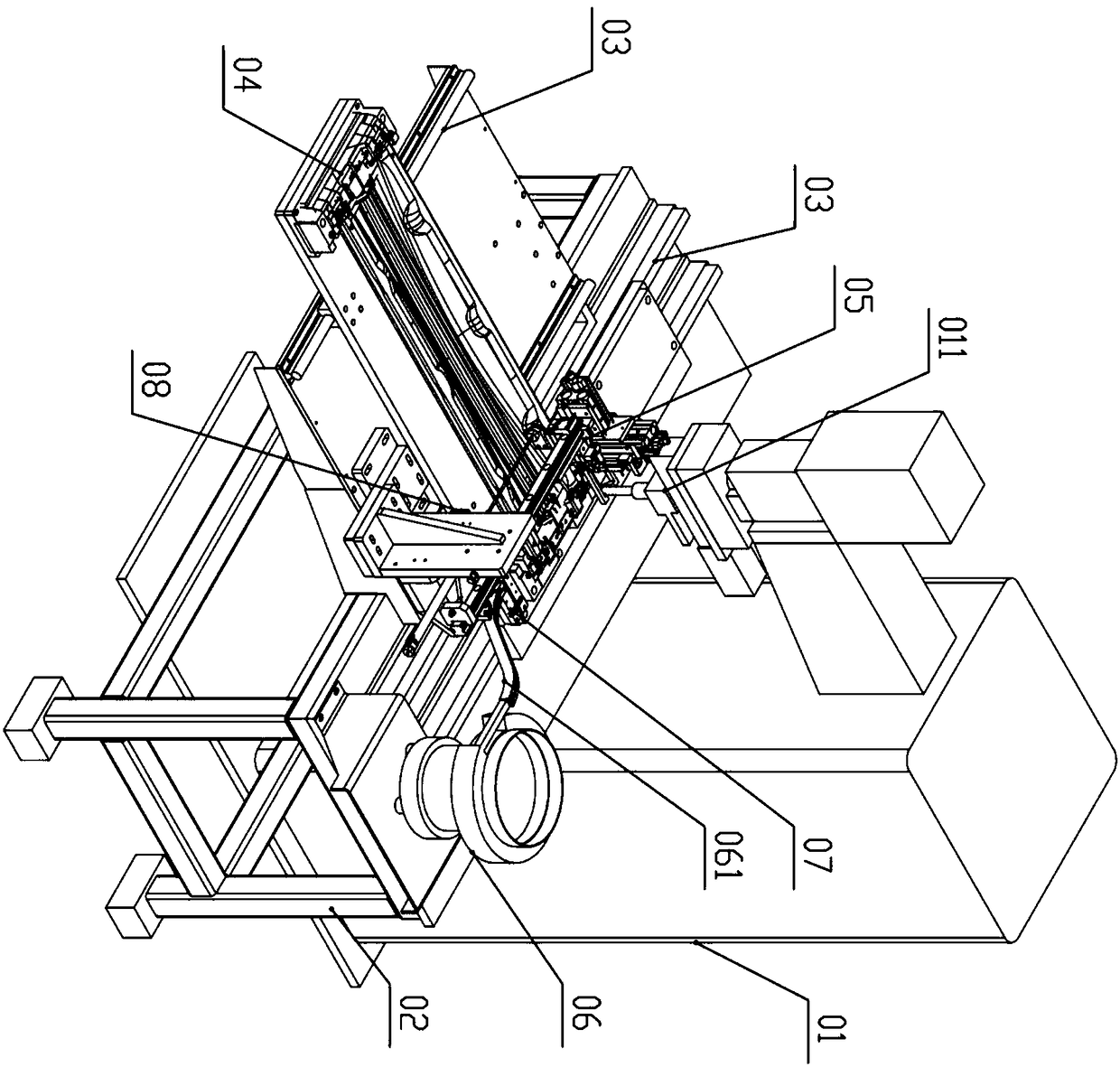

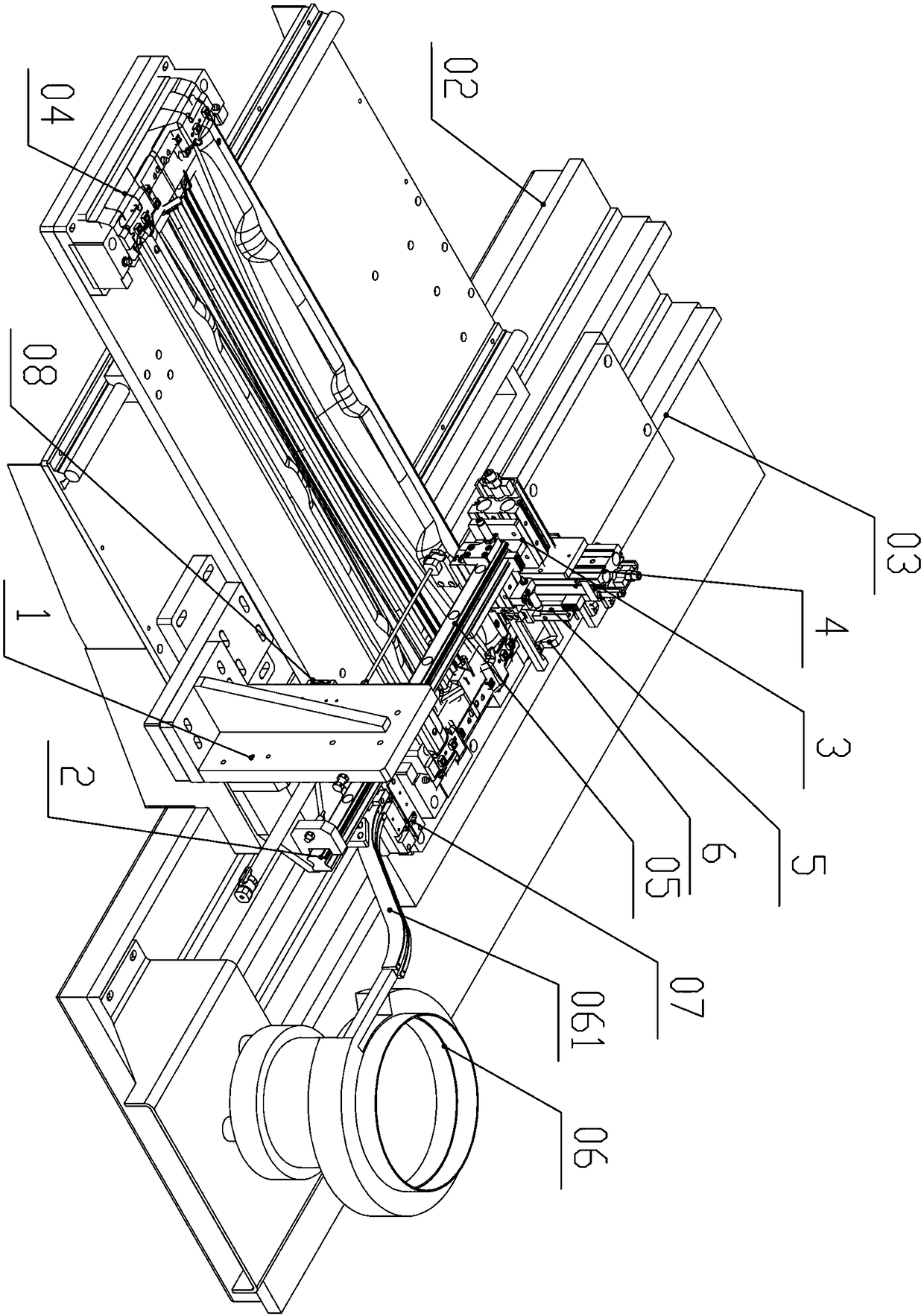

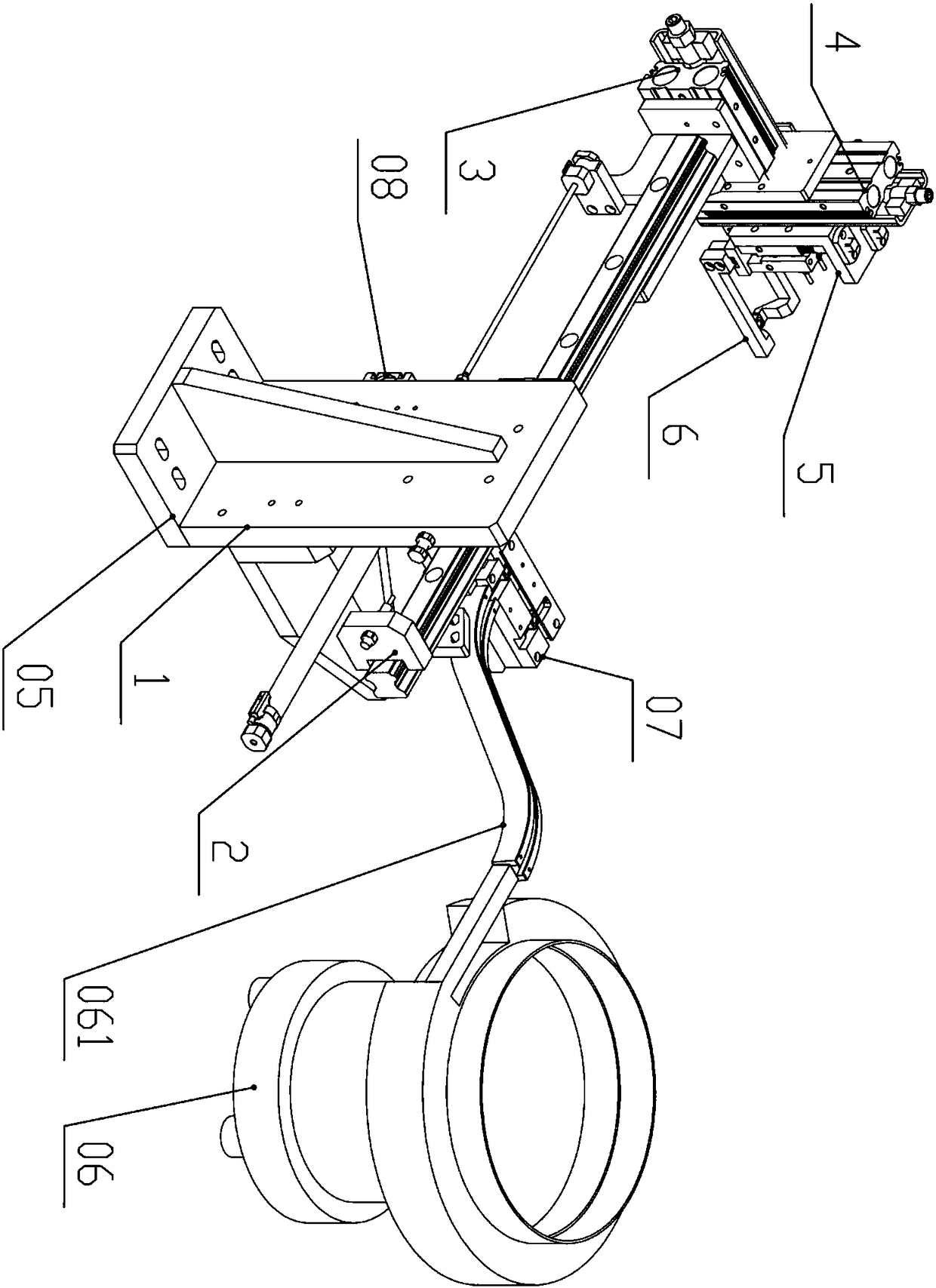

[0035] Figure 1 to Figure 10A nut spot welding automation device according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a spot welder 01 and a workbench 02. The workbench 02 is located below the spot welder 01. The spot welder 01 has a vertically downward upper electrode welding head 011, and the workbench 02 is below the welding head 011. In the middle of the workbench 02, there is a moving part 03 that can move linearly. The moving part 03 is slidably connected to the workbench 02 through a slide rail slider. The upper side of the moving part 03 is fixed with a profiling positioning part 04. There are several positioning columns, and the product is fixed on the upper surface of the profiling positioning part 04, and the product is located under the welding head 011.

[0036] A vibration pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com