Automobile bumper carrying and classified storage equipment

A technology of automobile bumper and storage equipment, which is applied in the field of automobile bumper handling and classification storage equipment, which can solve the problems of low efficiency, large floor area, large labor force, etc., and achieve the goal of increasing capacity, avoiding leakage and pollution, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

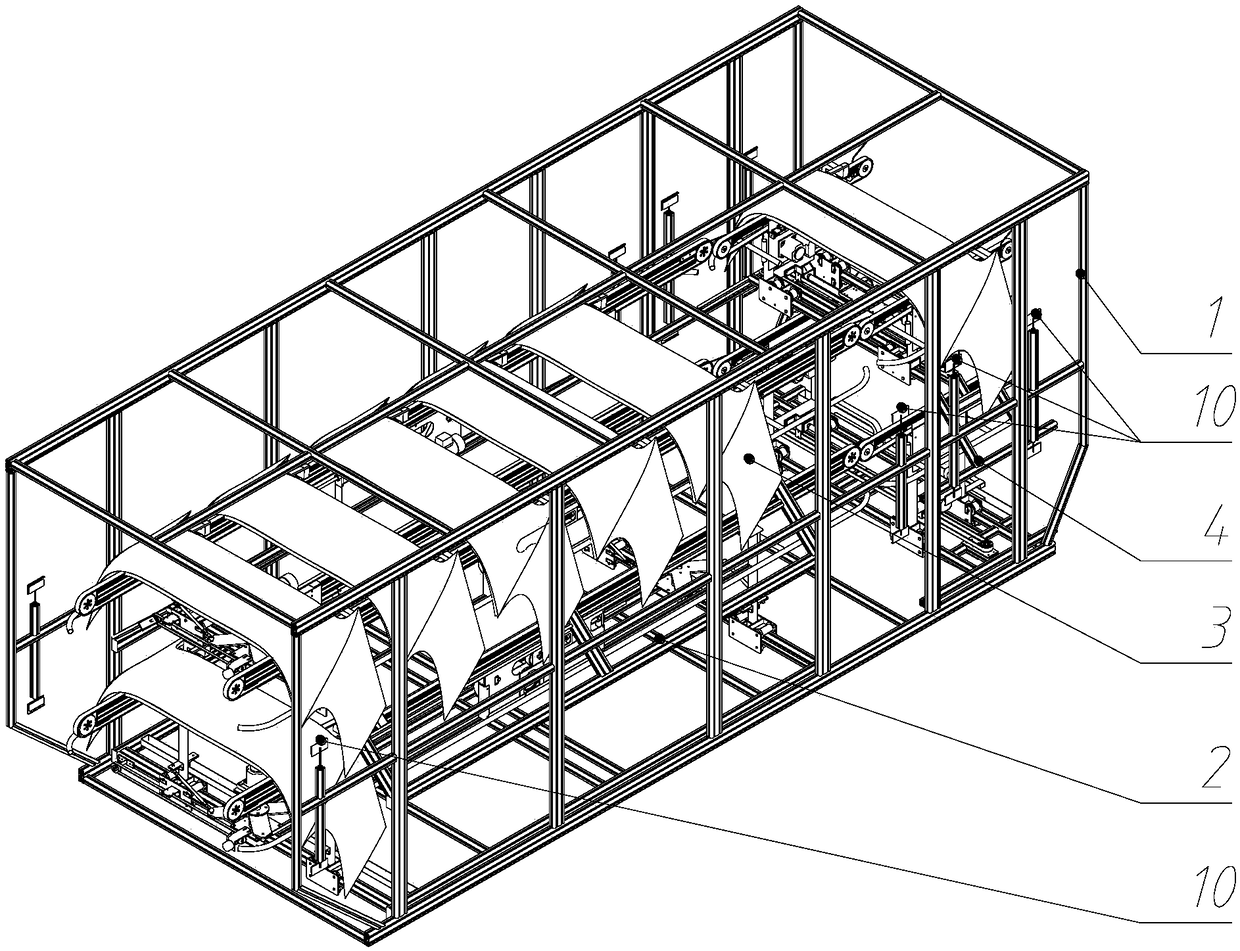

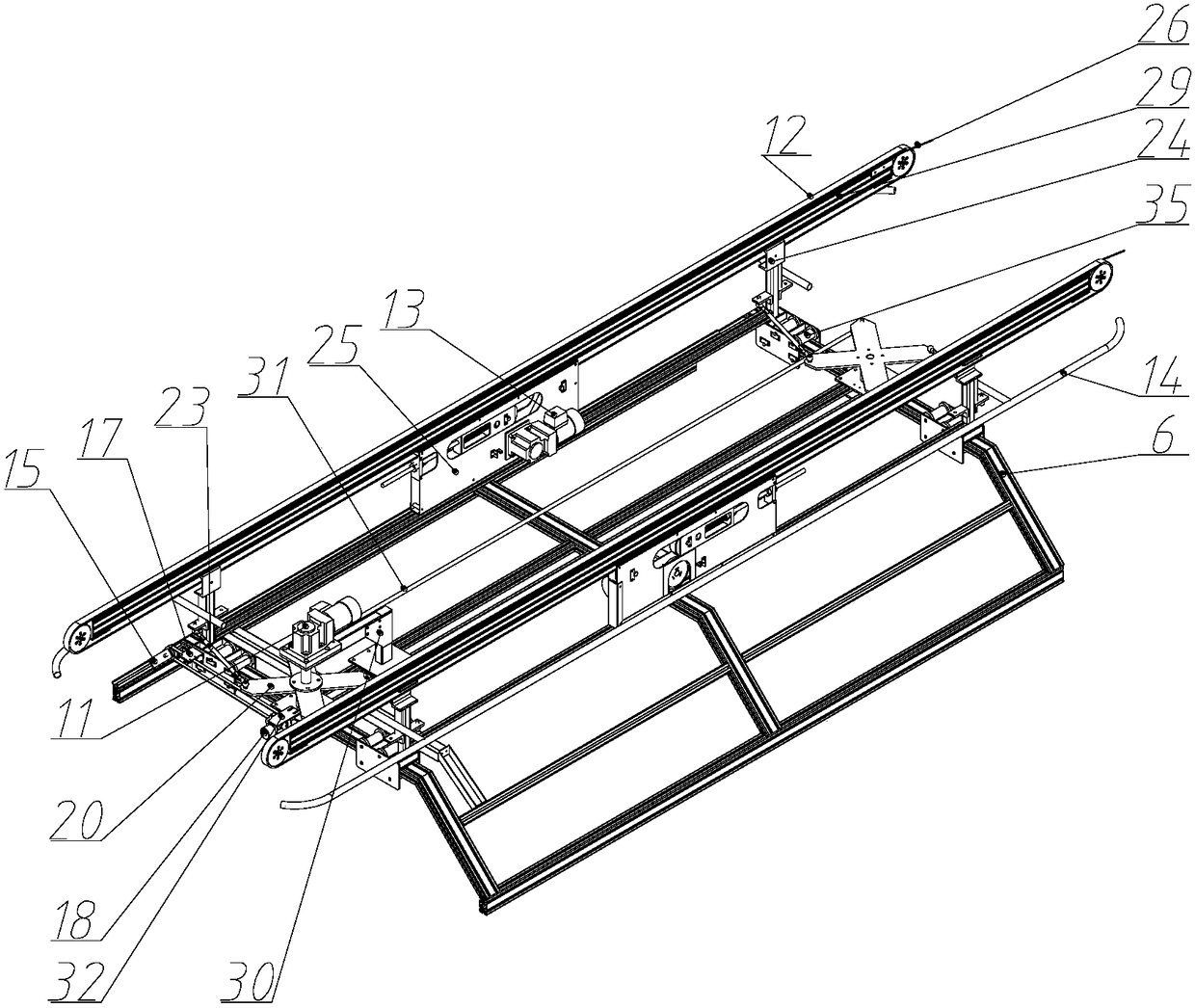

[0034] The invention provides a kind of automobile bumper handling classification storage device (see Figure 1-15 , referred to as equipment), is characterized in that the equipment includes a frame 1, a front storage position 2, an end storage position 4 and a grating sensor 10; The end of the warehouse position 4 is used to detect the storage and delivery of the automobile bumper 3;

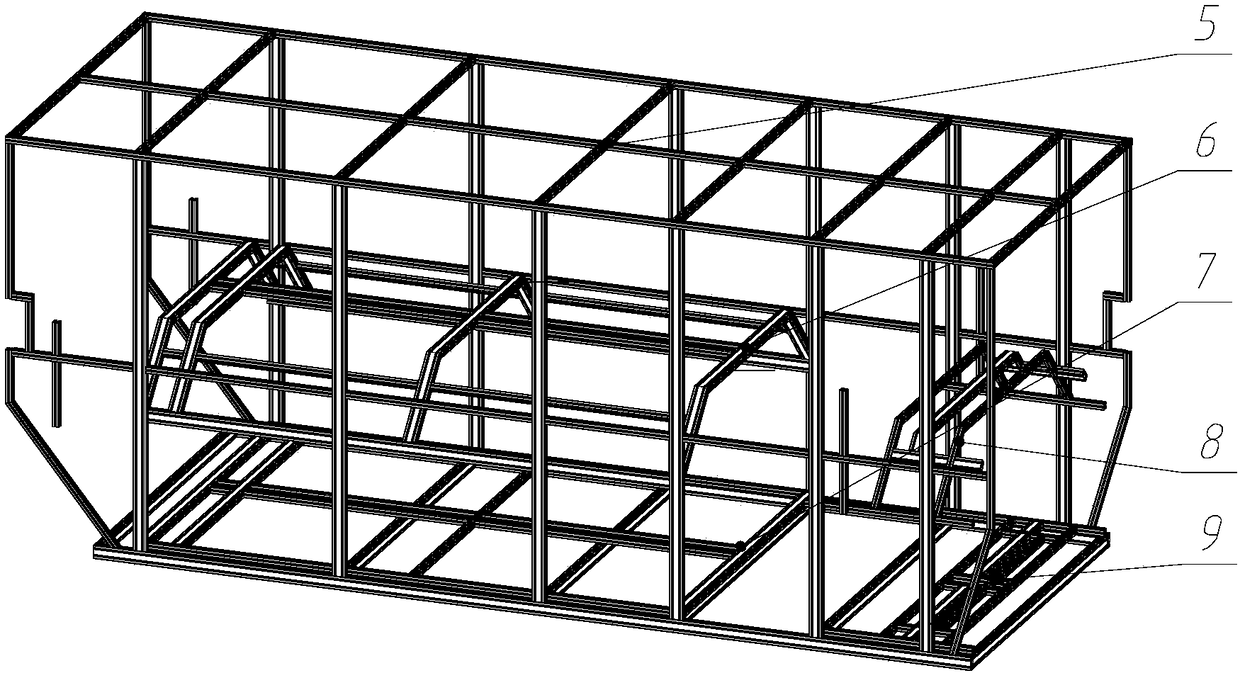

[0035] The frame 1 adopts aluminum profiles; the frame 1 includes a dust-proof frame 5, a front-end storage position oblique support frame 6, a front-end storage position straight support frame 7, an end storage position oblique support frame 8 and an end storage position straight support frame 9; The dust-proof frame 5 is the main structure of the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com